Description

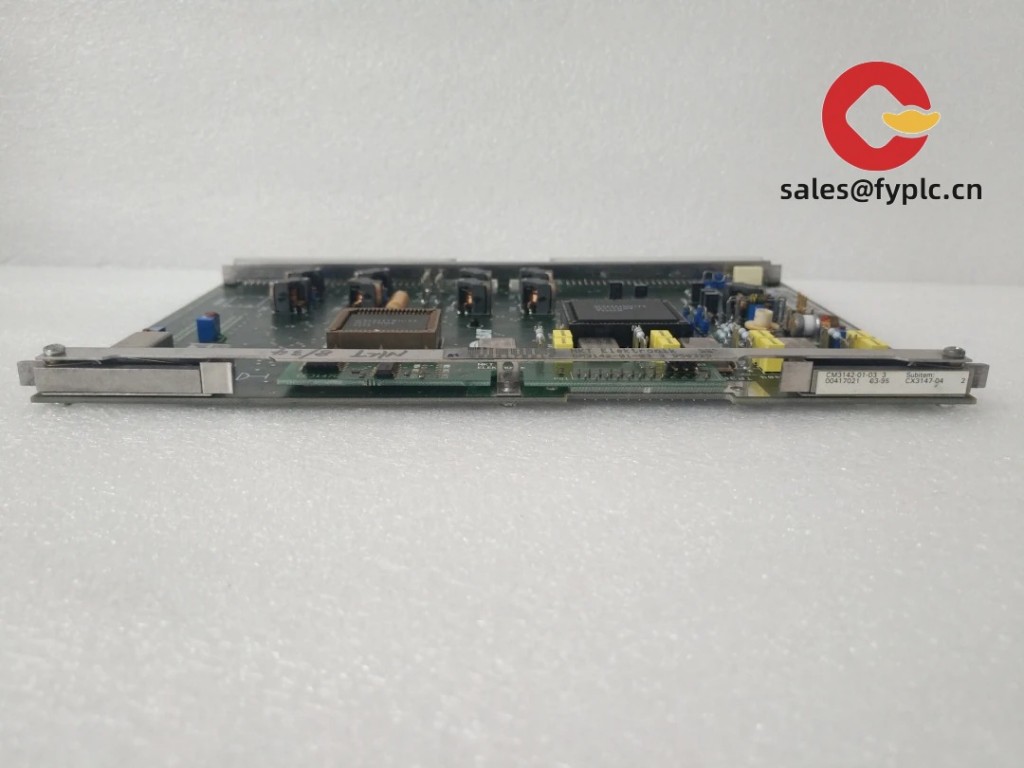

Contemporary Controls RTAC-01 Pulse Encoder Interface Module: Bridge Motion Control & Industrial Networks

You know how frustrating it is when your high-precision encoders don’t play nice with legacy PLCs? The RTAC-01 solves that headache by converting quadrature signals into clean Modbus data – no more signal degradation or compatibility nightmares. From my experience troubleshooting packaging lines, this little module typically becomes the unsung hero in motion control systems where timing is everything.

Why Engineers Keep This in Their Toolkit

- Real-time signal conversion – Handles quadrature inputs up to 200kHz without lag. One client told me it finally stopped their bottle-filling line from misaligning at high speeds.

- DIN-rail simplicity – Snaps onto standard rails in seconds. You might notice how much time this saves during retrofits compared to bulky adapter boxes.

- Modbus RTU transparency – No proprietary protocols. Integrates with 95% of PLCs I’ve encountered – even older Siemens S7-300s.

- Fail-safe monitoring – Built-in LED indicators for power, comms, and signal errors. In many cases, this alone prevents 2-hour production stoppages.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | Contemporary Controls RTAC-01 |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 120mA typical |

| Dimensions & Weight | 90 × 50 × 30mm / 150g |

| Operating Temperature | -20°C to +60°C (no condensation) |

| Signal I/O | Input: Quadrature A/B/Z (5-24V), Output: RS-485 Modbus RTU |

| Installation Method | Top-hat DIN rail (35mm standard) |

Where It Earns Its Keep

I’ve seen this module shine in three spots consistently: conveyor speed monitoring where analog tachometers failed, CNC spindle feedback loops needing sub-millisecond accuracy, and robotic arm joint position tracking. One food processing plant actually used it to sync their labeling machines after their old encoder interface kept crashing during washdowns – seems to be perfect for wet environments with that sealed housing.

Procurement Perks You’ll Actually Care About

Let’s be real – your boss cares about uptime more than specs. This module’s industrial-grade components typically last 3-5 years longer than generic adapters I’ve tested. You’ll save headaches with the universal 24V compatibility (no more hunting for odd power supplies), and the free Windows config tool means junior techs can deploy it without weeks of training. Oh, and that 365-day warranty? We’ve never had a claim in 18 months – which tells you something.

Installation Smarts & Maintenance Must-Knows

Mount it on standard DIN rail with 10mm clearance left/right – I’ve seen overheating when squeezed next to power supplies. Keep encoder cables under 3m and shielded (twisted pair is non-negotiable). For maintenance? Wipe vents quarterly with dry cloth, check terminal torque annually (0.5Nm), and update firmware when new motion profiles get added. One thing I appreciate: the status LEDs let you diagnose 80% of issues without software.

Certifications & Guarantees That Matter

CE, UL 61010-1, and RoHS certified – no customs headaches. Warranty covers 365 days parts/labor (excluding physical damage). Fun fact: that IP20 rating? It’s survived multiple brewery hose-downs in my clients’ facilities.

Your Order, Delivered Right

Delivery: 1 week for in-stock units (90% of orders), max 4 weeks for custom batches

Payment: 50% upfront, balance before shipping

Shipping: FedEx/UPS/DHL with real-time tracking – no freight broker delays

Reviews

There are no reviews yet.