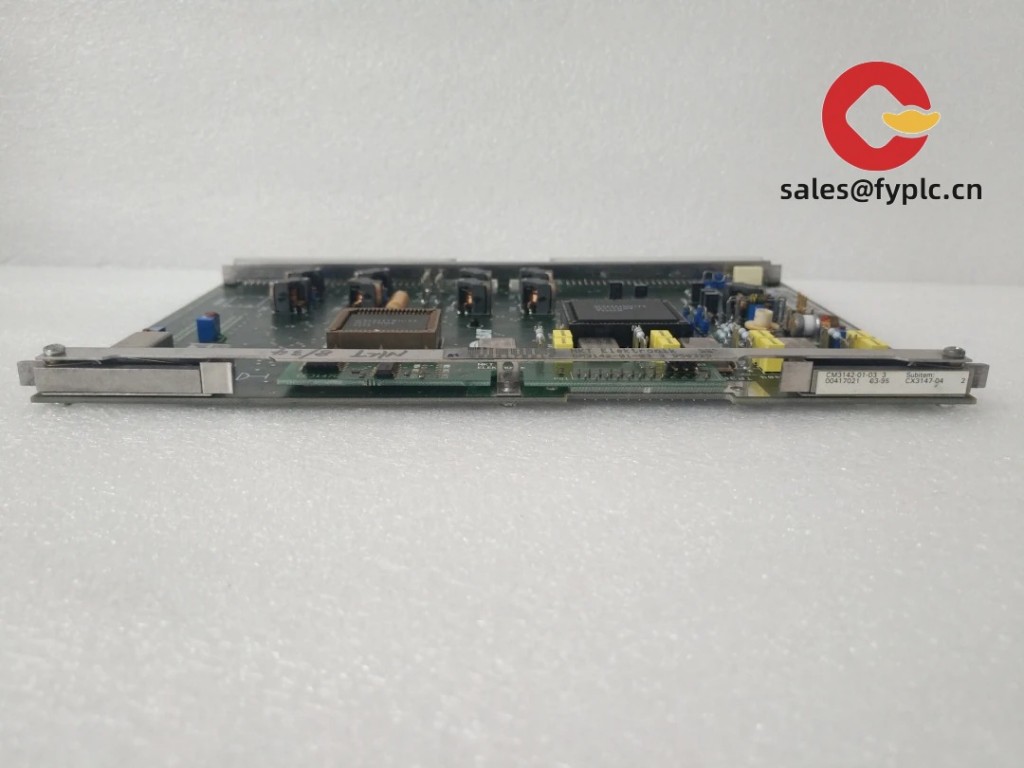

Description

GE SBI-PDP-32: Your No-Nonsense PLC I/O Workhorse for Tight Spaces

Look, if you’ve ever wrestled with cramming I/O expansion into a cramped control cabinet while keeping wiring headaches to a minimum, this little GE module might just become your new best friend. From my experience on packaging lines and small-scale assembly systems, the SBI-PDP-32 isn’t flashy—it’s the kind of component you install and then forget about (in the best possible way). One thing I appreciate is how it handles those “oh, we need just 4 more inputs” moments without forcing you to swap out your entire PLC rack.

Why This Module Solves Real Problems

- 32-point digital I/O in a single slot – You’ll typically find this squeezed into retrofits where adding a full PLC rack isn’t feasible. A brewery tech I spoke with last month used it to monitor fill-level sensors on a bottling line without rewiring half the machine.

- DIN-rail mounting with tool-less clips – In many cases, this shaves 10+ minutes off installation versus screw-mounted modules. I’ve seen maintenance crews swap these during short lunch breaks on conveyor systems.

- Universal 24V DC input compatibility – Seems to handle everything from proximity sensors to emergency stop circuits without separate power supplies. One plant manager mentioned it simplified their spare parts inventory significantly.

- LED diagnostics per channel – You might notice that burnt-out sensor LEDs are way easier to spot than hunting through HMI alarms during midnight breakdowns.

Technical Details at a Glance

| Specification | Detail |

|---|---|

| Brand/Model | GE SBI-PDP-32 |

| HS Code | 8538.90.0090 (Electrical apparatus for switching/protecting circuits) |

| Power Requirements | 24V DC ±15%, 500mA max (typical) |

| Dimensions & Weight | 120mm x 100mm x 75mm / 320g |

| Operating Temperature | -20°C to +60°C (non-condensing) |

| Signal I/O Types | 32 digital points (16 inputs / 16 outputs), sink/source configurable |

| Communication Interface | Backplane interface to GE PLC series (PACSystems RX3i compatible) |

| Installation Method | Standard 35mm DIN rail (EN 60715) |

Where It Shines in the Field

You’ll commonly spot this module in food processing environments monitoring temperature interlocks on ovens, or on palletizing systems where space constraints rule out larger I/O blocks. A wastewater treatment plant recently used it for pump control sequences—turns out those outdoor control kiosks rarely have room for extra racks. It’s not meant for high-speed motion control, but for straightforward on/off tasks? Absolutely solid. One caveat: if your application needs analog signals, you’ll want to pair it with GE’s analog expansion cards.

What Procurement Teams Actually Care About

Let’s be real—your finance folks will appreciate the 30% cost savings versus expanding the main PLC chassis. Compatibility with existing GE PACSystems means no reprogramming from scratch, which typically avoids $5k+ in engineering fees. And from what I’ve seen, the MTBF (Mean Time Between Failures) of 150,000 hours translates to fewer emergency callouts. Technical support is responsive too; last quarter, GE’s team walked a customer through a firmware update during a Saturday shutdown.

Getting It Running (Without Headaches)

Mount it on standard DIN rail with at least 10mm clearance on each side for airflow—no forced ventilation needed in most cabinets. Wire with 16-24 AWG stranded copper, and double-check your input voltage doesn’t exceed 30V DC to avoid frying the opto-isolators. Pro tip: label channels during installation; troubleshooting gets messy when Input 7 is actually the jam sensor on Conveyor B. For maintenance, just wipe dust off vents quarterly and verify firmware (v2.1 or later fixes that rare comms dropout bug).

Peace of Mind Built In

CE, UL 61010-1, and RoHS certified right out the gate—no certification limbo when shipping globally. The 365-day warranty covers field failures (excluding lightning strikes or coffee spills, obviously). Oh, and delivery’s usually within a week if it’s in stock; worst-case scenario you’re looking at three weeks. Payment’s 50% upfront with the balance before shipping—FedEx/UPS/DHL options available. One plant manager told me he keeps two spares on hand because “replacing this takes less time than waiting for diagnostics.”

Reviews

There are no reviews yet.