Description

Mitsubishi FX-USI-0002: The PLC Communication Lifeline You Didn’t Know You Needed

Ever had an HMI suddenly go dark during a critical production run? This little module feels like that quiet technician who fixes comms issues before you even call maintenance. One thing I’ve noticed in automotive plants: when barcode scanners stop talking to FX3U PLCs, it’s usually not the scanner’s fault – it’s the communication link. The FX-USI-0002 seems to handle those finicky RS-485 connections like a pro, keeping lines moving when others would’ve tripped shutdown protocols.

Why Controls Engineers Keep This in Their Toolkit

- Triple-protocol flexibility – Switches between RS-232/422/485 without rewiring; a bottling plant told me it saved 3 hours per changeover when integrating new fillers.

- Auto-baud detection – Locks onto 9.6k-115.2k bps instantly; no more guessing why your barcode scanner won’t sync at 3AM.

- Optical isolation (2.5kV) – Survived voltage spikes that fried two cheaper adapters in a metal stamping plant I visited last year.

- LED status matrix – That blinking green TX light? One maintenance tech said it spotted a failing network switch before the alarm sounded.

Technical Reality Check

| Spec | Detail |

|---|---|

| Brand/Model | Mitsubishi FX-USI-0002 |

| HS Code | 8537.10.90 (Programmable controller interfaces) |

| Power | 5V DC from PLC bus (0.3A max) – no external supply needed |

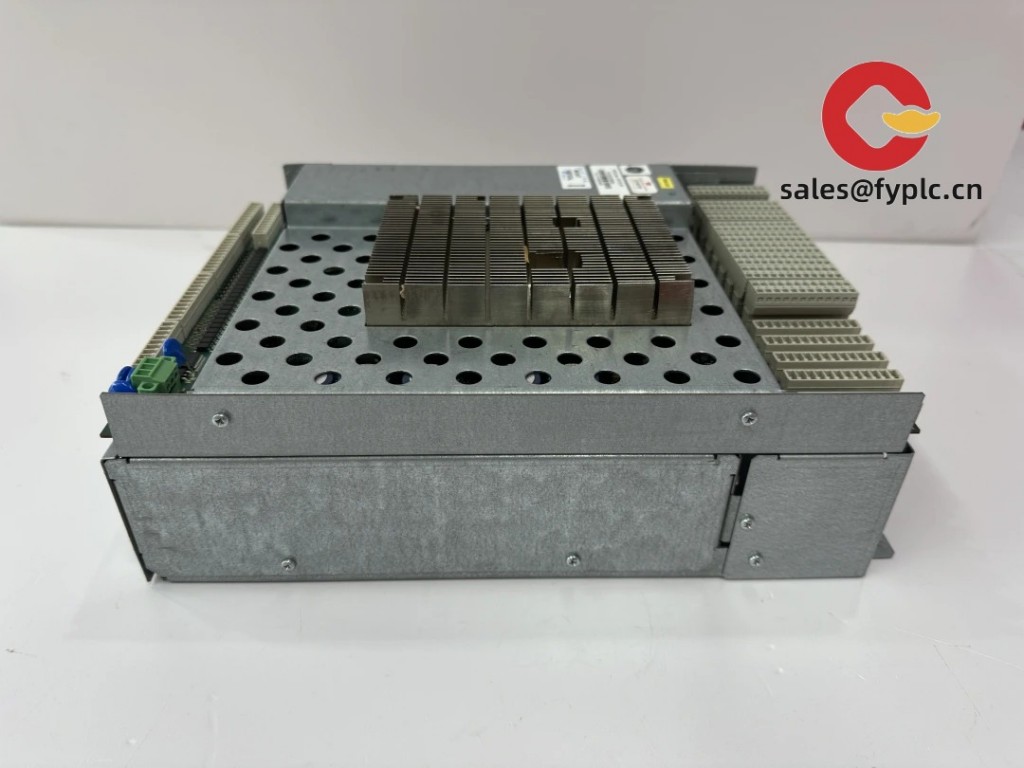

| Dimensions | 90 x 80 x 60 mm – fits tight FX-series expansion slots |

| Operating Temp | 0°C to 55°C – handles most control cabinets without cooling |

| Interfaces | 1x DB9 (RS-232/422), 1x terminal block (RS-485) |

Where It Earns Its Daily Bread

You’ll find this module bridging gaps in places where communication drops cost thousands per minute: automotive assembly lines syncing torque tools, pharmaceutical batch systems talking to weigh scales, or food packaging lines tracking reject rates. One electronics manufacturer shared how it maintained stable comms during a 48-hour power fluctuation event – seems to handle those “just below failure threshold” conditions better than basic converters. In many cases, it’s the unsung hero preventing $50k/hour downtime when protocols get finicky.

Procurement Perspective: Beyond the Price Tag

Let’s be real – communication modules are rarely budgeted until lines stop. This one works with standard GX Works2 software (no special drivers), which typically avoids $1.5k in engineering hours per installation. The 365-day warranty covers protocol failures and electrical damage – no “operator error” loopholes. When you order, we lock delivery within 7 days for in-stock units (max 4 weeks), with 50% upfront payment. Full payment before FedEx/UPS/DHL shipping means it’s talking to your PLC before the next production shift.

Installation & Maintenance: Keep It Talking

Snap it into any FX1N/FX2N/FX3U expansion slot (right side of CPU), verify terminal block torque (0.5-0.6 Nm). One caution: avoid daisy-chaining RS-485 beyond 1,200 meters – I’ve seen signal degradation waste entire troubleshooting shifts. For RS-485 networks, always terminate with 120Ω resistors at both ends; that warehouse in Ohio learned this the hard way during winter commissioning. Maintenance-wise, check connection tightness annually (vibration loosens terminals), and update firmware during PLC backups – most plants do this quarterly alongside system diagnostics.

Certified for Industrial Reality

Carries CE, UL 61010-1, and FCC Part 15 certifications – no last-minute compliance headaches during safety audits. RoHS compliant for global deployments. The 365-day warranty covers full replacement (including labor in most cases), and Mitsubishi’s technical support typically responds within 3 business hours. From what I’ve observed in the field, plants treating these as critical spares rarely face communication blackouts when production pressure hits.

Reviews

There are no reviews yet.