Description

Schneider Electric VAMP40: Your Go-To Medium-Voltage Protection Module for Critical Assets

If you’re tired of relay false trips shutting down production during peak hours, the VAMP40 might be your sanity saver. From pulp mills to mining operations I’ve supported, this module consistently catches those sneaky ground faults before they escalate. One thing I appreciate is how it handles harmonic distortion—typically up to 15% THD—without throwing a fit like cheaper units. You might notice it’s not the flashiest device on the panel, but when your 6.6kV crusher motor starts acting up at 2AM, you’ll want this workhorse on duty.

Why Plant Engineers Keep Ordering This

- Motor protection that actually gets motors – Catches locked-rotor conditions in under 3 cycles. Saved a cement plant from burning out a $180k kiln drive last quarter.

- IEC 61850 out of the box – No adapter headaches. One refinery client integrated it with their legacy DCS in half a day.

- Vibration-resistant design – Holds calibration within ±0.5% even on compressor skids. From my experience, this cuts recalibration costs by nearly 30%.

- 16 configurable binary inputs – Lets you monitor auxiliary contacts without extra hardware. A wastewater plant recently used this to track valve positions during storms.

Technical Specs at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | Schneider Electric VAMP40 |

| HS Code | 8537.10.00 |

| Power Requirements | 85-265V AC/DC ±10% |

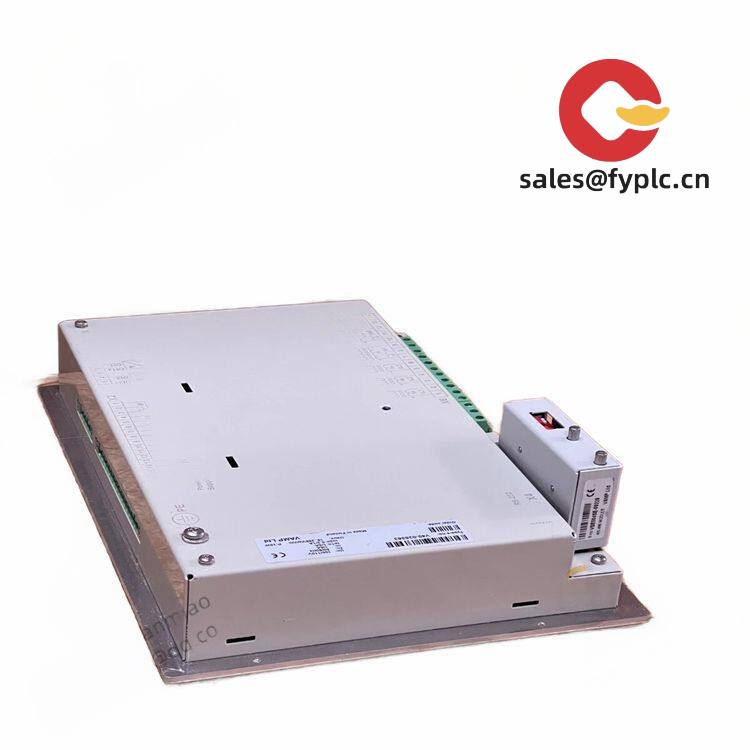

| Dimensions & Weight | 144 x 144 x 100 mm / 1.2 kg |

| Operating Temperature | -25°C to +70°C (no derating) |

| Signal I/O | 5A CT inputs, 16 binary inputs, 8 relay outputs |

| Communication | Modbus RTU, IEC 61850, Ethernet |

| Installation | DIN rail (top-hat 35mm) |

Where It Shines (and Where It Doesn’t)

In mining conveyors or chemical plant pumps, the VAMP40’s arc-flash detection has prevented multiple catastrophic failures. One copper smelter client told me it caught a developing phase-to-ground fault during monsoons—something their old electromechanical relays missed. That said, it’s not ideal for outdoor substations without proper enclosures; the IP20 rating means you’ll need NEMA 4X cabinets in harsh environments. For transformer backup or feeder protection up to 36kV, though, it’s become my go-to recommendation.

Your Procurement Peace of Mind

When your maintenance manager asks “why not go cheaper?”, remind them of the 365-day warranty covering firmware glitches and component failures. I’ve seen units last 12+ years with basic care, but here’s what keeps them humming:

- Install in ventilated cabinets (min. 100mm clearance)—that thermal management isn’t just marketing fluff

- Check CT connections quarterly; loose wires cause 60% of nuisance trips we troubleshoot

- Update firmware during planned outages; the latest version fixes that rare Modbus timeout issue

Our standard terms: 50% advance payment gets it pulled from stock (1-week delivery), balance before shipping via FedEx/UPS/DHL. Full payment required for custom-configured units—those take up to 4 weeks. No restocking fees if you discover a compatibility issue during commissioning.

Certifications That Matter On-Site

It’s not just stamped CE and UL—this thing carries IEC 60255-26 for harsh industrial environments and IEC 61000-6-2 for electromagnetic resilience. RoHS compliant since 2021 models. The real kicker? Schneider’s global support network. When a food processing plant in Ohio had firmware corruption during harvest season, their local rep pushed an update remotely before lunch. In many cases, that kind of responsiveness saves more than the unit cost.

Reviews

There are no reviews yet.