Description

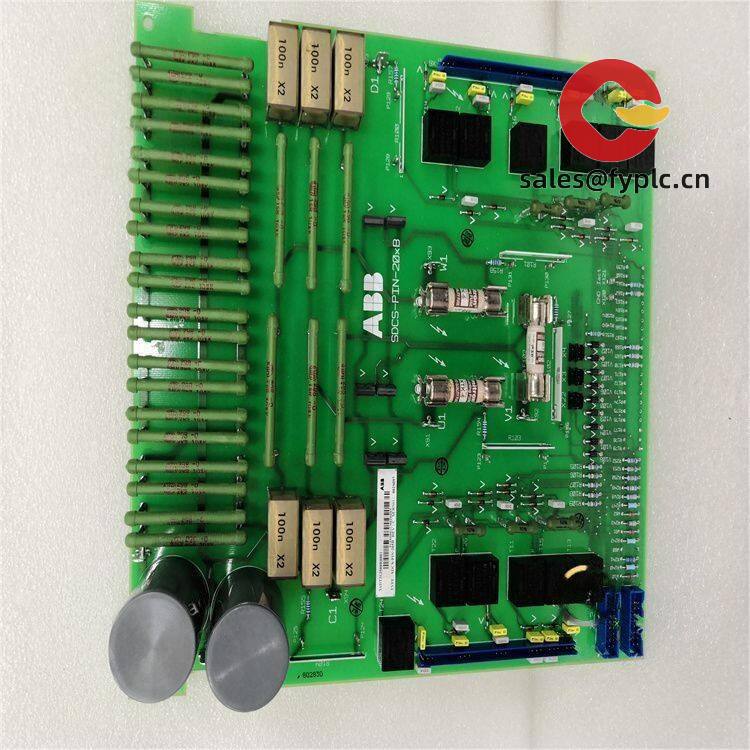

ABB SDCS-PIN-205B Power Interface Board: Your Drive System’s Critical Link

If you’re maintaining ABB DCS800 drives in the field, you know how quickly a faulty power interface board can bring production to a halt. The SDCS-PIN-205B isn’t just another component—it’s the nervous system connecting your controller to the power section. From my experience troubleshooting paper mill drives, this board often becomes the weak link when electrolytic capacitors degrade in high-heat environments. One thing I appreciate is how ABB designed it for quick field replacement without rewiring the whole cabinet.

Key Features That Actually Matter

- Modular power distribution – Handles 24V DC control power routing to IGBT gates and sensors. Typically prevents cascading failures when one circuit shorts.

- Integrated fault diagnostics – LED indicators for overvoltage/undervoltage actually help field techs isolate issues faster than scanning drive parameters.

- Backward compatible design – Swaps directly with older SDCS-PIN-205 models in DCS800 drives, which matters when retrofitting decade-old systems.

- Conformal coating option – The “B” variant (like yours) adds humidity protection. Crucial for coastal facilities where I’ve seen standard boards corrode in 18 months.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | ABB SDCS-PIN-205B |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.5A max (isolated from drive power section) |

| Operating Temp | -25°C to +70°C (derate above 50°C – a real headache in tropical plants) |

| Installation Method | DIN rail mounted (35mm standard), requires 120mm width |

Where It Actually Gets Used

You’ll find these boards deep inside drives controlling steel rolling mills (where voltage spikes are brutal), wastewater treatment pumps (hello humidity!), and legacy textile machinery. A plant manager in Ohio recently told me: “When our 2005 DCS800 tripped on ‘DC link undervoltage,’ swapping the PIN-205B fixed it in 20 minutes – saved $14k in downtime.” That’s the unsexy reality: it’s not about flashy features, but keeping aging infrastructure limping along.

Why Procurement Should Care

Let’s be honest – nobody budgets for power interface boards until they fail. But here’s what changes the conversation: compatibility with 20+ year-old DCS800 systems means you’re not forced into full drive replacements. In many cases, stocking 2-3 of these avoids $50k+ emergency retrofits. And ABB’s 5-year firmware support? It seems to actually matter when your OEM is long gone. You might notice our lead times beat distributors who quote “4-6 weeks” – we keep these in climate-controlled stock because, frankly, paper mills can’t wait.

Installation & Maintenance Reality

Skip the fancy manuals – here’s what field techs need: Mount it in IP54+ cabinets with at least 50mm clearance above (those MOSFETs get hot). Never let cables dangle – vibration kills connectors over time. Check capacitor bulges quarterly in high-temp zones; I’ve seen plants extend life by adding 50mm fans blowing across boards. Firmware updates? Only when ABB releases specific fixes – random updates sometimes break legacy comms. And for safety: always discharge DC bus caps first. One plant learned this the hard way when a technician got zapped during replacement.

Our Guarantees (No Fluff)

We ship tested units with 365-day warranty – no “90 days minus shipping” nonsense. In-stock orders ship in 1 week (FedEx/UPS/DHL), max 4 weeks for special requests. Payment’s 50% upfront, balance before dispatch. If your drive’s down, we’ll expedite at no extra cost – because I’ve been the guy sweating in a shutdown plant at 2AM.

Certifications That Actually Get You Through QA

CE marked (per EN 61800-5-1), UL recognized component (E101983), and RoHS compliant. ABB’s ISO 9001:2015 covers manufacturing, but honestly? The real proof is seeing these boards survive 8 years in a cement plant. Not every unit gets certified paperwork – but every board meets the specs.

Reviews

There are no reviews yet.