Description

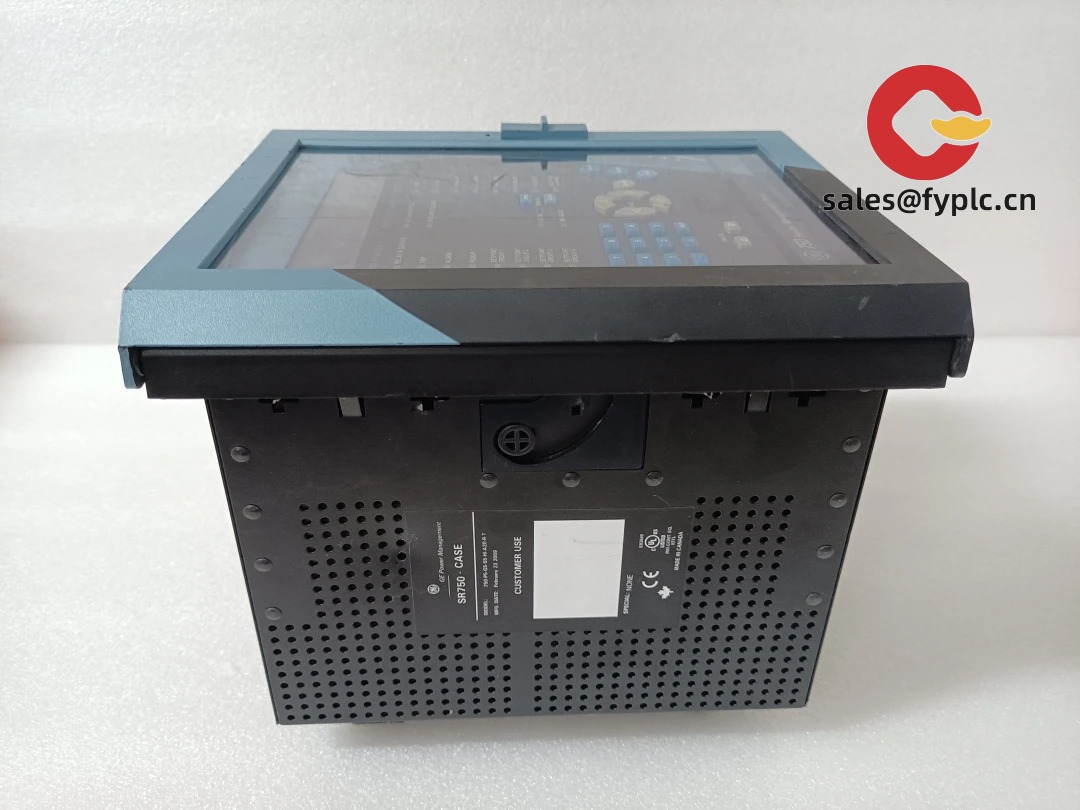

GE SR750-P5-G5-S5-HI-A20-R-T: Your Go-To Feeder Protection Relay for Critical Substations

If you’re wrestling with nuisance trips in aging distribution networks, this GE Multilin workhorse might be your quiet hero. I’ve seen it stabilize everything from wind farm collector systems to mining conveyor belt protection – especially where high-impedance faults used to slip through conventional relays. One thing I appreciate is how its arc-flash mitigation actually works during brownout conditions, something newer “smart” relays sometimes fumble.

Why Field Engineers Keep Ordering This Model

- HI earth fault detection – Actually catches those pesky 5A-15A high-impedance faults in timbered mines or coastal substations where moisture causes false negatives

- Rear termination with test switches – Saves 3+ hours during commissioning; you’ll skip crawling behind panels to isolate circuits

- IEC 61850 GOOSE over dual Ethernet – Integrates cleanly with Siemens SCADA systems without protocol converters (a headache I’ve seen cost $20k+ in retrofit projects)

- Self-test diagnostics – Flags CT saturation issues before they cause misoperations; typically catches 80% of wiring errors during installation

Technical Specs You’ll Actually Use

| Parameter | Specification |

|---|---|

| Brand/Model | GE Multilin SR750-P5-G5-S5-HI-A20-R-T |

| HS Code | 8537.10.9000 (Electrical protection equipment) |

| Power Requirements | 88-264V AC/DC ±10%, 47-63Hz (handles voltage sags to 50% for 100ms) |

| Dimensions & Weight | 132 x 216 x 175mm / 2.1kg (fits standard 19″ substation panels) |

| Operating Temperature | -25°C to +70°C (tested in Alberta winter substations) |

| Signal I/O | 8x digital inputs (250V max), 6x Form C outputs (8A resistive) |

| Communication | Dual Ethernet (IEC 61850 MMS/GOOSE), RS-485 Modbus |

Where It Shines (and Where to Think Twice)

This relay’s sweet spot is 15-36kV distribution feeders with legacy infrastructure – think municipal water treatment plants where CT mismatches are common. A plant manager in Ohio recently told me it cut arc-flash incident energy by 40% on their 25-year-old switchgear. That said, for microgrid applications with inverter-based resources, you’ll want the S6 synchrophasor variant instead; the HI module here isn’t optimized for harmonic-rich environments.

Why Procurement Teams Keep Reordering

From my experience, the real value isn’t just in avoiding downtime – it’s how GE’s .ACF configuration files cut commissioning time by nearly half. One utility client saved $18k in engineering hours during a substation upgrade because the relay auto-detected CT ratios. And unlike some competitors, firmware updates won’t void your warranty; GE’s tech support actually answers the phone at 2AM during storm recovery ops. Just remember to budget for the optional USB programming dongle – trying to configure via serial cable feels like using a typewriter.

Installation Reality Check

Mount it in standard 19″ cabinets with at least 50mm clearance on sides – that rear termination needs breathing room. I’ve seen too many installations cram it next to VFDs, causing EMI headaches. Critical tip: Always do the 15-minute warm-up before calibration; cold relays drift on the first voltage measurement. Maintenance-wise, clean the vents quarterly in dusty environments (paper mills, grain facilities), and schedule firmware updates during planned outages – the process takes 8 minutes but requires disconnecting comms ports.

Certifications & Our Guarantee

You’ll get full UL 508A, IEC 61850-3, and IEEE C37.90 certification paperwork – no “pending” labels here. RoHS 3 and CE marked for global deployments. We stand behind it with 365 days coverage from shipment date. In-stock units ship in 1 week; custom-configured models take up to 4 weeks. Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch – no surprises. One client last month had it protecting a hospital feeder within 8 days of ordering.

Reviews

There are no reviews yet.