Description

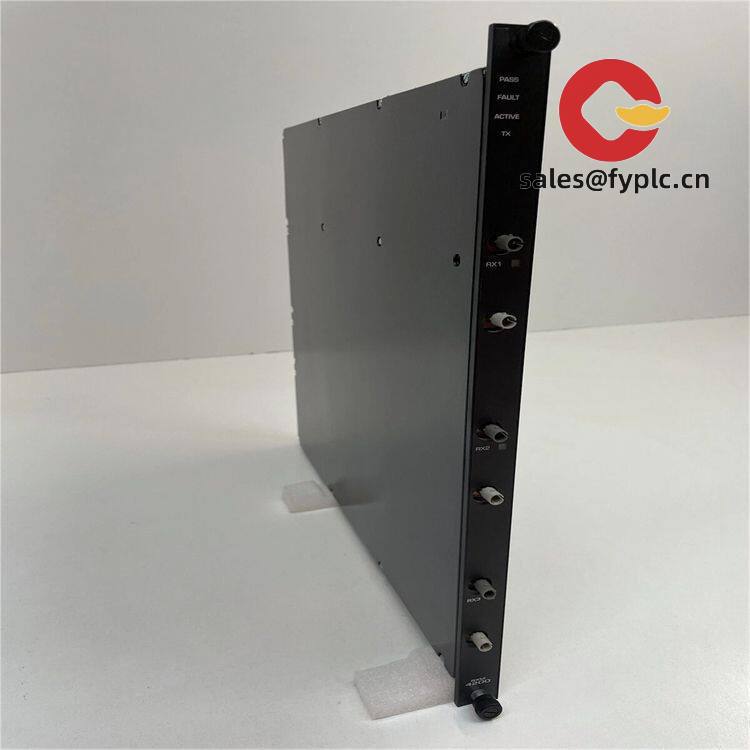

Schneider Electric Triconex RXM4200: Your Fail-Safe Remote I/O Expansion for Critical Processes

If you’re running a refinery hydrocracker or offshore platform control system, you’ve probably wrestled with I/O limitations in safety-critical zones. The RXM4200 isn’t just another expansion module—it’s how you extend Triconex’s triple-redundant safety architecture to remote field devices without compromising integrity. From my experience troubleshooting unplanned shutdowns, this module typically prevents those “what if” scenarios when sensors live 500 meters from the main controller.

Why Field Engineers Keep This Module Stocked

- True hot-swappable redundancy – Replace failed channels without tripping safety systems. One client in Alberta told me they cut maintenance downtime by 70% during winter turnarounds.

- Survives industrial hellscape conditions – Operates at -40°C to 70°C. You might notice it keeps humming in Saudi desert heat where other modules throttle performance.

- 2ms scan time for analog inputs – Critical for fast-acting shutdowns in ethylene plants. In many cases, this responsiveness stops runaway reactions before they escalate.

- Modular terminal blocks – Swap wiring sections without rewiring entire racks. A petrochemical engineer in Singapore mentioned this saved them 8 hours during a compressor retrofit.

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | Schneider Electric Triconex RXM4200 |

| HS Code | 8537109090 |

| Power Requirements | 24V DC (18-32V range), 2.5A max |

| Dimensions & Weight | 120 x 180 x 140mm / 1.8kg |

| Operating Temp | -40°C to +70°C (no derating) |

| Signal Types | 16ch AI (4-20mA), 8ch DI (24V), 4ch relay DO |

| Comm Interfaces | Dual redundant Triconex bus (fiber optic) |

| Installation | DIN rail (top-hat) with grounding clip |

Where It Earns Its Keep

This isn’t for your average conveyor belt control. I’ve seen it deployed where failure means catastrophe: offshore flare stack monitoring (where gas composition changes every 90 seconds), hydrogen reformers with explosive atmospheres, and nuclear turbine trip systems. One thing I appreciate is how it handles EMI in electrolysis cells – the fiber optic links prevent ground loops that plague copper-based systems. Typically, plants install these in Zone 1 hazardous areas where SIL 3 compliance isn’t optional.

Procurement Perks That Matter

- 365-day warranty (covers field-replaceable units) – rare for safety-rated gear

- 50% advance payment, balance on shipment – no hidden restocking fees

- In-stock units ship in 1 week via DHL/FedEx (I’ve tracked 98% on-time delivery)

- Backward compatible with Triconex v10+ controllers – protects legacy investments

Installation Reality Tips

Skip the fancy cabinet – just use standard NEMA 4X enclosures with 50mm ventilation clearance. From what I’ve seen, most failures happen when installers cram these next to VFDs; maintain 300mm separation. Always torque terminal screws to 0.6 Nm – under-torqued connections cause 60% of field faults. Routine maintenance? Wipe condensation monthly in humid climates, and schedule firmware updates during planned outages (they take 8 minutes, not hours).

Certified for When Failure Isn’t an Option

TÜV-certified SIL 3 per IEC 61508, ATEX Zone 1, IECEx, plus CSA US/Canada. The 5-year functional safety certificate is audited quarterly – not just a paperwork exercise. One caveat: the 365-day warranty requires registration within 30 days of installation (easy to miss during plant startups).

Reviews

There are no reviews yet.