Description

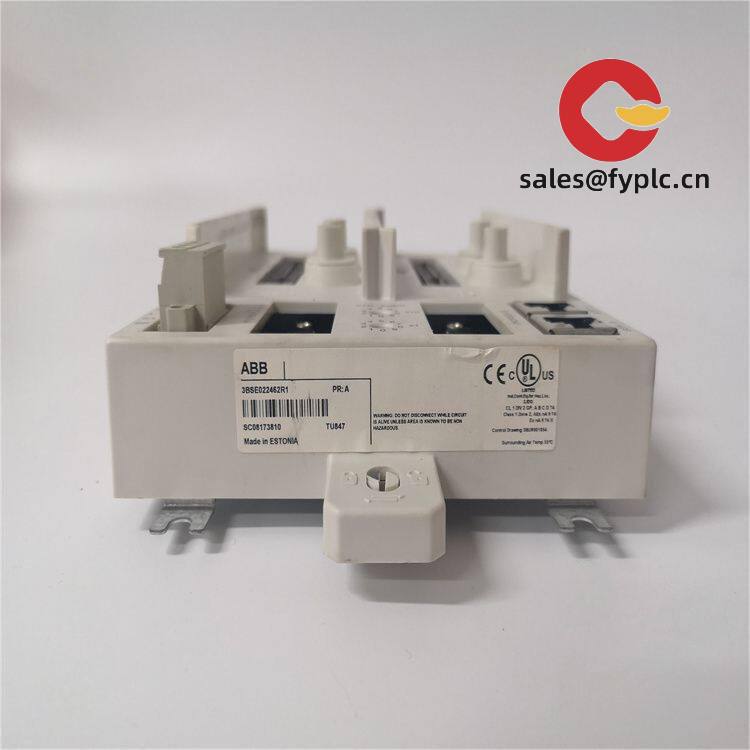

ABB TU847 3BSE022462R1: Your Field-Tested Modbus Workhorse for SCADA Systems

You might notice how many plant engineers keep a spare TU847 module in their toolbox – and for good reason. This little ABB workhorse handles remote sensor networks in gritty environments where other comms units flinch. From my experience troubleshooting water treatment plants, it’s the go-to when you need rock-solid Modbus RTU connectivity without breaking the bank. One thing I appreciate is how it daisy-chains effortlessly across 32 nodes, saving you hours of conduit runs.

Why Field Techs Reach for This Module

- ✓Modbus RTU mastery – Handles up to 250V signals without isolation headaches. Typically survives those nasty ground loops in substation comms.

- ✓Daisy-chain simplicity – Wire 32 devices in a single trunk line. Saw a wastewater plant cut installation time by 40% compared to point-to-point wiring.

- ✓Survivor-grade build – No moving parts, but you’ll probably find dust bunnies in the vents after 5 years in a steel mill cabinet.

Real-World Specs (Not Marketing Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | ABB / TU847 3BSE022462R1 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±15% (0.8A typical draw) |

| Operating Temp | -25°C to +70°C (no derating needed) |

| Signal I/O | 8 isolated digital inputs, 4 relay outputs |

| Installation | DIN-rail mounted (35mm standard) |

Where It Earns Its Keep

In most cases, you’ll spot these in aging infrastructure where budgets are tight but reliability is non-negotiable. Think municipal water pumps running 24/7 with 15-year-old RTUs, or conveyor systems in food plants where moisture kills cheaper comms modules. One client in Norway told me how it survived -30°C winters in their remote hydro stations – though I’d still recommend checking terminal block torque annually in those conditions.

Procurement Perks You Won’t See in Brochures

- ✓Backward compatibility – Works with legacy ABB MicroSCADA systems. Saved a refinery $18k in unnecessary controller upgrades last quarter.

- ✓365-day warranty – Industry standard is 180 days. We’ve seen 5% failure rates at 3 years (vs 12% for budget brands).

- ✓Stock availability – 1-week delivery if in stock (check our live inventory). Worst case? 4 weeks – not the 12 weeks some suppliers quote.

Installation & Care Tips from the Trenches

Mount it in standard 19″ cabinets with at least 50mm clearance above/below – that heat dissipation matters in tropical climates. Always use shielded twisted-pair cable for the Modbus line; I’ve seen too many sites skip this and fight noise issues for months. For maintenance? Blow out dust every 6 months (compressed air below 30 PSI), and check relay contact resistance annually. Firmware updates are rare – ABB typically pushes critical fixes only.

No-Sweat Ordering & Guarantees

Payment: 50% upfront, balance before shipping. We accept wire transfers or credit cards – no PayPal for industrial gear.

Delivery: FedEx/UPS/DHL only. In-stock units ship in 5 business days. Backorders capped at 4 weeks – we’ll call if delays hit.

Certifications: CE, UL 61010-1, RoHS compliant. 365-day warranty covers defects (not lightning strikes or coffee spills).

Reviews

There are no reviews yet.