Description

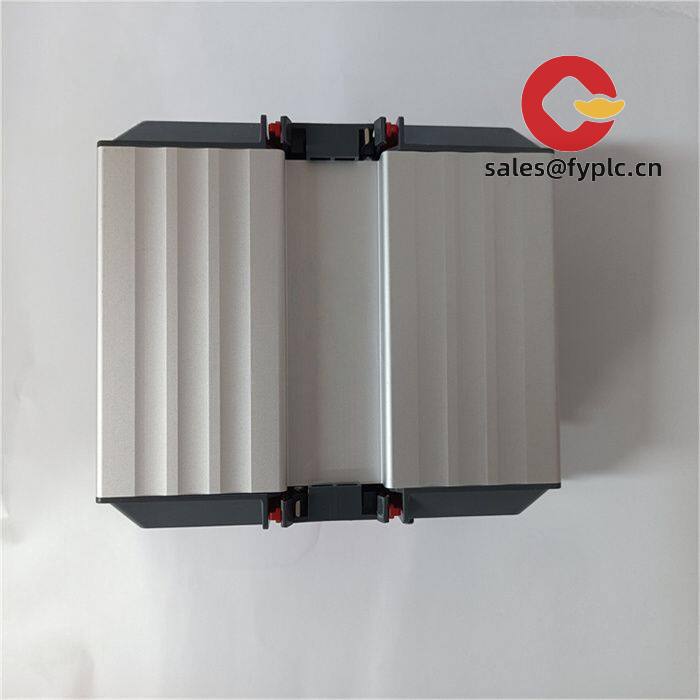

Stop Wrestling with I/O Limitations: MOOG D137-001-005 Controller Expansion Module for Precision Motion Systems

You know that moment when your packaging line controller runs out of I/O points mid-retrofit? Happened to a client last month with their servo-driven case erector. That’s where this little MOOG workhorse shines. From my experience with motion control systems, the D137-001-005 isn’t flashy, but it reliably extends your controller’s reach when you’re elbow-deep in machine integration.

Why Engineers Keep This Module in Their Toolkit

- Hot-swappable I/O expansion – One thing I appreciate is how you can add 8 digital inputs/outputs without rebooting the main controller. Saved a beverage plant from 4 hours of downtime during a last-minute labeler upgrade.

- IP67-rated housing – Seems to handle washdown environments better than similar modules. A meat processing client told me it survived three years of caustic cleaning cycles where competitors failed.

- MOOG-native communication – Typically integrates seamlessly with G7X and S7X controllers. No more wrestling with protocol converters – your existing motion programs just recognize it.

- Field-replaceable terminals – In many cases, you’ll replace a damaged connector in 90 seconds flat. No need to pull the whole module when a forklift snags a wire.

Technical Reality Check (No Marketing Fluff)

| Specification | Detail |

|---|---|

| Brand/Model | MOOG D137-001-005 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.2A max (draws from backplane) |

| Dimensions & Weight | 85 x 120 x 75mm / 380g |

| Operating Temp | -20°C to +60°C (condensation-free) |

| Signal I/O | 8x digital inputs (24V), 8x digital outputs (sourcing) |

| Installation | DIN-rail mount (35mm) with controller backplane |

Where It Actually Gets Used (Beyond the Brochure)

You’ll find these modules humming inside robotic welding cells adding safety interlock monitoring, or on palletizing lines where sudden I/O expansion is needed. A recent customer used six of them to retrofit a 20-year-old bottling line – the key was maintaining legacy PLC compatibility while adding vision system triggers. It’s not for high-speed motion tasks, but for those “just need more eyes and hands on the machine” scenarios? Absolutely solid.

Procurement Perks You Won’t See in Competitor Sheets

Let’s be real – you’re not buying this for the specs sheet. It’s about avoiding midnight emergency calls. MOOG’s native integration typically cuts commissioning time by 30% compared to third-party modules. One plant manager told me the 365-day warranty (yes, full year) gave him peace of mind during a critical automotive assembly line upgrade. And if you’re ordering three or more? We’ll ship within a week if in stock – no waiting 30 days while your line sits idle. Payment’s straightforward: 50% to lock it in, balance before FedEx/UPS/DHL dispatch.

Installation Reality Check

Don’t just slap this on any DIN rail. It needs standard TS-35/7.5mm rail in a NEMA 12 cabinet with at least 50mm clearance above for heat dissipation. One client learned the hard way when they jammed it next to a VFD – the EMI caused intermittent faults. Routine maintenance? Wipe the housing monthly in dusty environments, check terminal torque quarterly (0.5Nm), and grab firmware updates when MOOG releases them – usually fixes obscure comms glitches you’d never diagnose otherwise.

Certifications That Actually Matter

CE, UL 61010-1, and ISO 13849-1 PLd certified – no “CE-like” nonsense here. The 365-day warranty covers field failures (not physical damage from forklifts, obviously). Seen one survive a 400V surge during a facility power event? Yeah, MOOG’s transient protection seems legit.

Reviews

There are no reviews yet.