Description

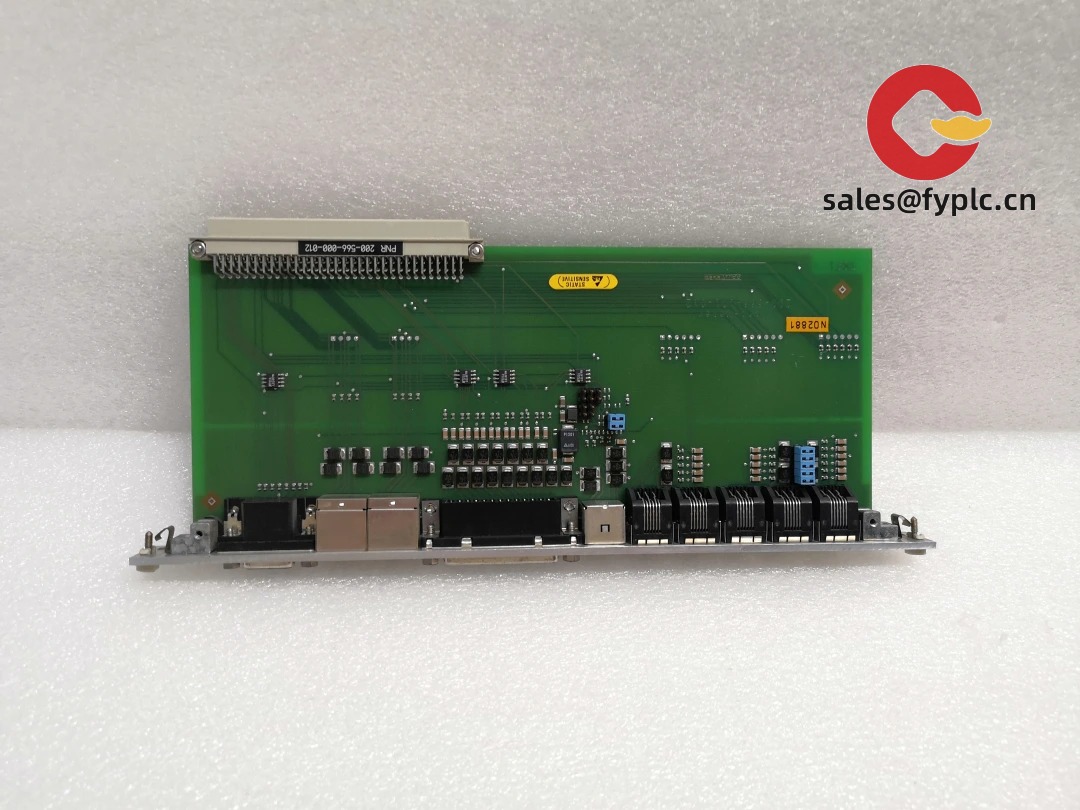

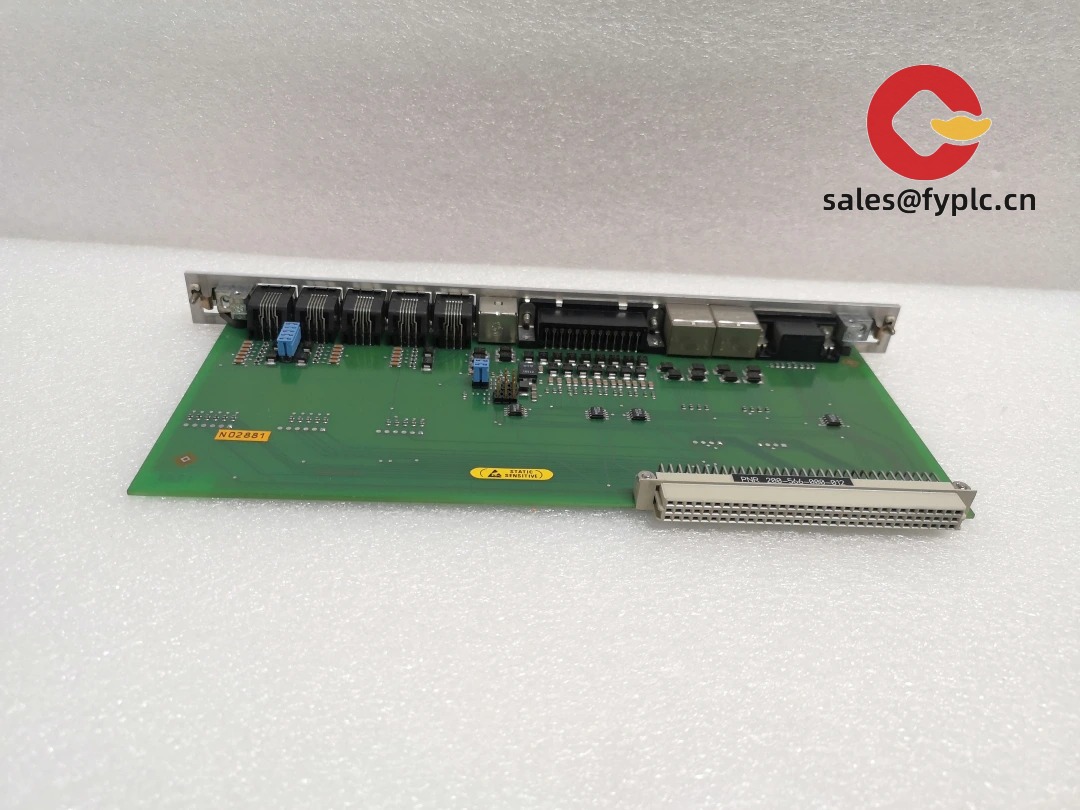

Vibro-meter VM600 IOCN Interface Module: Keep Your Turbine Monitoring Talking When It Matters Most

Let’s be real—you don’t want comms dropping during a critical turbine ramp-up. I’ve seen plants scramble when interface modules hiccup, but the VM600 IOCN (models 200-566-000-012 and 200-566-101-012) typically handles the chatter between your vibration sensors and control system like a seasoned translator. One thing I appreciate is how it slips into existing VM600 racks without fuss, keeping your gas turbine or compressor train data flowing even during those noisy startup sequences.

Why maintenance teams keep this module in their spares cabinet

- Hot-swap ready – Swap it out without killing power to the whole rack. Saved a refinery in Louisiana 12 hours of downtime last winter.

- Dual Ethernet ports – Creates a physical network ring so comms don’t collapse if a cable gets nicked during maintenance.

- Protocol translator – Converts VM600’s proprietary signals to Modbus TCP on the fly. Your DCS team won’t need custom drivers.

- Heartbeat monitoring – Alerts you 5 minutes before comms fail, not after. Feels like having a canary in the coal mine.

Technical specs you’d actually check on the datasheet

| Parameter | Specification |

|---|---|

| Brand/Model | Vibro-meter VM600 IOCN (200-566-000-012 / 200-566-101-012) |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24 VDC ±10%, 1.2A max (draws from VM600 backplane) |

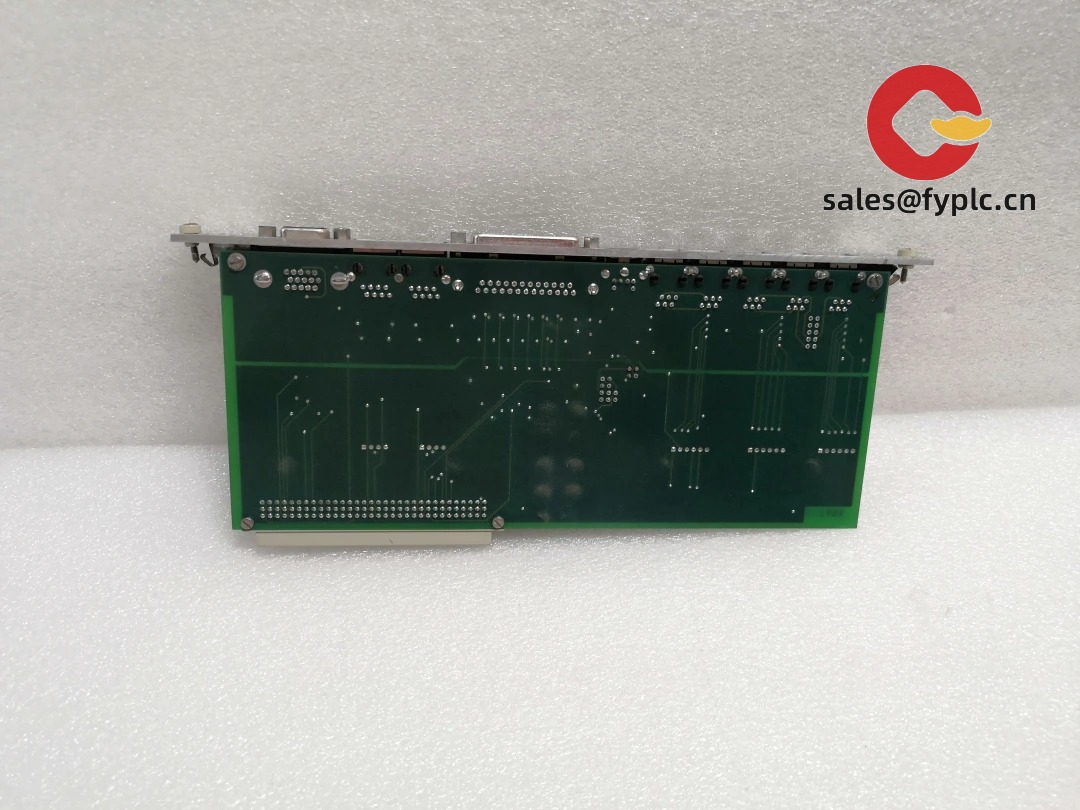

| Dimensions & Weight | 100mm x 160mm x 30mm / 380g (Eurocard format) |

| Operating Temperature | -20°C to +70°C (condensation-free environment) |

| Signal I/O | 4x isolated Modbus RTU (RS-485), 2x 10/100Mbps Ethernet |

| Installation | DIN rail or 19″ rack (VM600 chassis only) |

Where you’ll actually use this beyond the spec sheet

From offshore platforms to combined-cycle plants, this module’s sweet spot is connecting legacy VM600 vibration monitors to modern control rooms. A pipeline compression station in Alberta recently used it to feed bearing vibration data into their new SCADA system—without rewiring 47 sensor lines. You might notice it’s particularly clutch when retrofitting older turbines where the original comms hardware is long obsolete. One refinery maintenance lead told me: “It’s the only thing that keeps our 2008 VM600s talking to the 2023 DCS.”

What procurement actually cares about (beyond the price tag)

Look, your vibration monitoring system is only as good as its weakest comms link. This module’s value shows up when your reliability engineer isn’t fielding 3AM calls about dropped signals. In most cases, the hot-swap capability alone pays for itself by avoiding a single unscheduled shutdown. And since it’s built to GE’s industrial specs (not some generic PLC), you won’t waste weeks troubleshooting compatibility—just drop it in and watch the data flow. The 365-day warranty gives breathing room for those finicky commissioning phases.

Installation & maintenance realities

Mount it in a NEMA 4X cabinet with at least 50mm clearance on all sides—those Ethernet ports generate heat during sustained data bursts. Avoid sharing power feeds with VFDs; I’ve seen EMI corrupt comms when plants cut corners here. For maintenance, check the LED status weekly (green = happy, amber = “call support yesterday”), and update firmware during annual shutdowns. No calibration needed, but blow out dust from the vents every 6 months—turbine halls get gritty.

Certifications & the fine print you should scan

CE marked for EMC and low-voltage directives, UL 61010-1 certified (so your safety team won’t block installation), and RoHS compliant. The 365-day warranty covers defects but not “oops-I-plugged-240V-into-a-24V-port” scenarios. Stock units ship in 1 week; non-stock takes up to 4 weeks. Payment’s 50% upfront, balance before FedEx/UPS/DHL dispatch. Keep that PO handy—customs will ask for the HS code at 8537.10.9000.

Reviews

There are no reviews yet.