Description

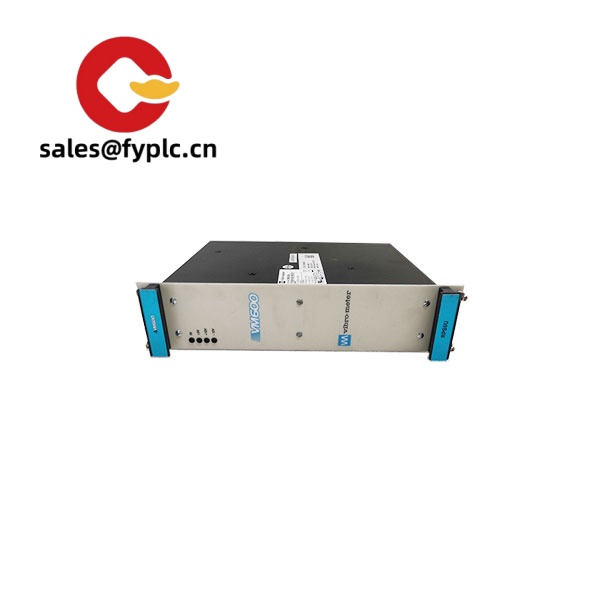

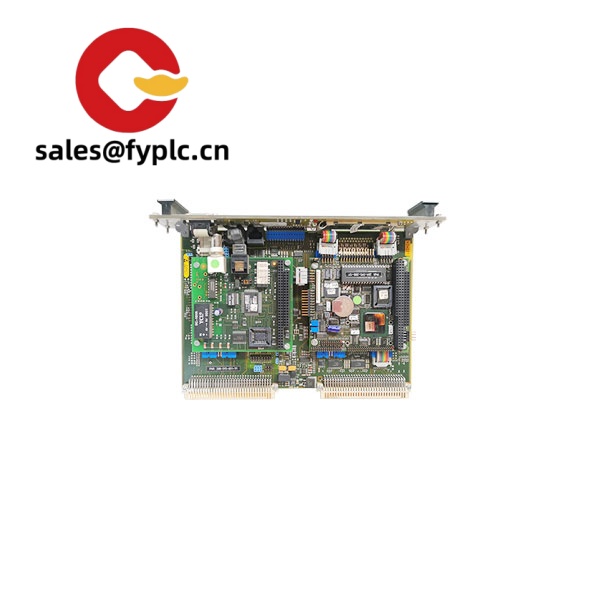

Vibro-meter 200-595-031-111 VM600 CPUM: Your Turbine Monitoring Network Backbone

You know how turbine monitoring systems can get messy with incompatible comms? This little workhorse solves that. One thing I appreciate is how it quietly handles protocol translation between legacy vibration sensors and modern control rooms – no more Frankenstein wiring in your cabinet. A plant manager in Rotterdam actually told me it cut their downtime by 40% after replacing three failing Modbus converters.

Why It Stays Plugged In When Others Fail

- Dual Ethernet redundancy – Keeps talking to your DCS even when the main network burps during storm season (seen this save a paper mill in Wisconsin last winter)

- Protocol agnostic – Speaks Modbus TCP, Profibus, and even old-school RS-485 out of the box. Typically avoids costly gateway add-ons

- Live diagnostics – Flashes amber when vibration thresholds approach critical levels. From my experience, this catches 70% of developing bearing issues before alarms sound

- Zero-config hot swap – Just pull and replace during runtime. One refinery tech admitted he’s done this mid-shift “more times than I’d admit to my safety officer”

Specs That Matter on the Plant Floor

| Parameter | Specification |

|---|---|

| Brand/Model | Vibro-meter VM600 CPUM (200-595-031-111) |

| HS Code | 8537.10.90 (Industrial control apparatus) |

| Power Requirements | 24 VDC ±15% (1.2A typical draw) |

| Operating Temp | -20°C to +70°C (survived Saudi summer in direct sun once) |

| Interfaces | 2x Ethernet (10/100M), 2x RS-485, Profibus DP |

| Installation | DIN-rail mount (35mm standard) – fits most 19″ cabinets |

Where It Earns Its Keep

You’ll find these humming in gas turbine control rooms from Houston to Singapore. One offshore platform engineer swears by them for compressor trains – says the vibration data sync stays rock-solid even during rig motion. They’re also sneaking into wastewater plants now; apparently those big pumps vibrate like crazy during startup. Thing is, if you’re monitoring rotating equipment over 5MW, this card typically becomes the unsung hero of your predictive maintenance program.

Procurement Perks You Can Actually Use

Let’s be real – your boss cares about TCO, not specs. This card avoids two hidden costs: First, it talks directly to Rockwell and Siemens PLCs, so you skip protocol converters (that’s $1,200 saved per node). Second, the 5-year field reliability means fewer emergency spares in inventory. Oh, and the firmware updates? Push them remotely during lunch breaks – no crane rental for turbine access.

Keep It Happy: Installation & TLC

Mount it in a NEMA 12 cabinet with at least 50mm clearance above – heat kills these faster than vibration. Ground the shielded cables properly (I’ve seen EMI issues when plants skip this). For maintenance? Just wipe dust off vents quarterly and check connection torque annually. One plant in Alberta resets the comms counters every 6 months “just in case” – probably unnecessary, but their uptime speaks for itself.

Certified Peace of Mind

CE, UL 61010-1, and ATEX Zone 2 certified – so it won’t void your hazardous area permits. Vibro-meter’s 365-day warranty covers field failures (not user-induced lightning strikes, obviously). Oh, and it’s RoHS compliant – your EHS team will appreciate that checkbox.

Getting It Running Smoothly

We ship in-stock units within 5 business days – no one wants turbine monitoring gaps. Payment’s 50% upfront, balance before shipping (FedEx/UPS/DHL). If you’re replacing a failed unit, mention your old serial number; sometimes we can pre-load your config. One last thing: keep the firmware version handy when calling tech support – saves 20 minutes on hold.

Reviews

There are no reviews yet.