Description

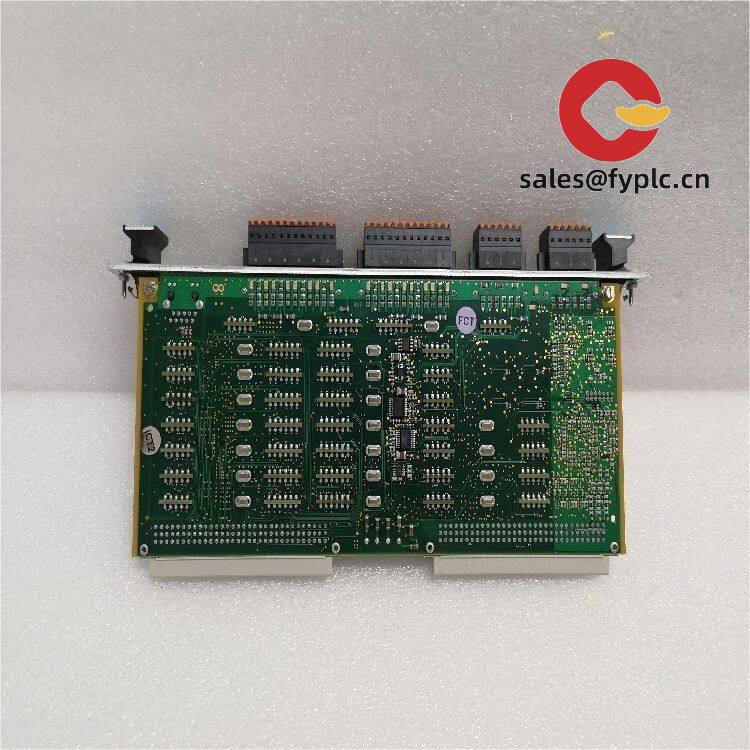

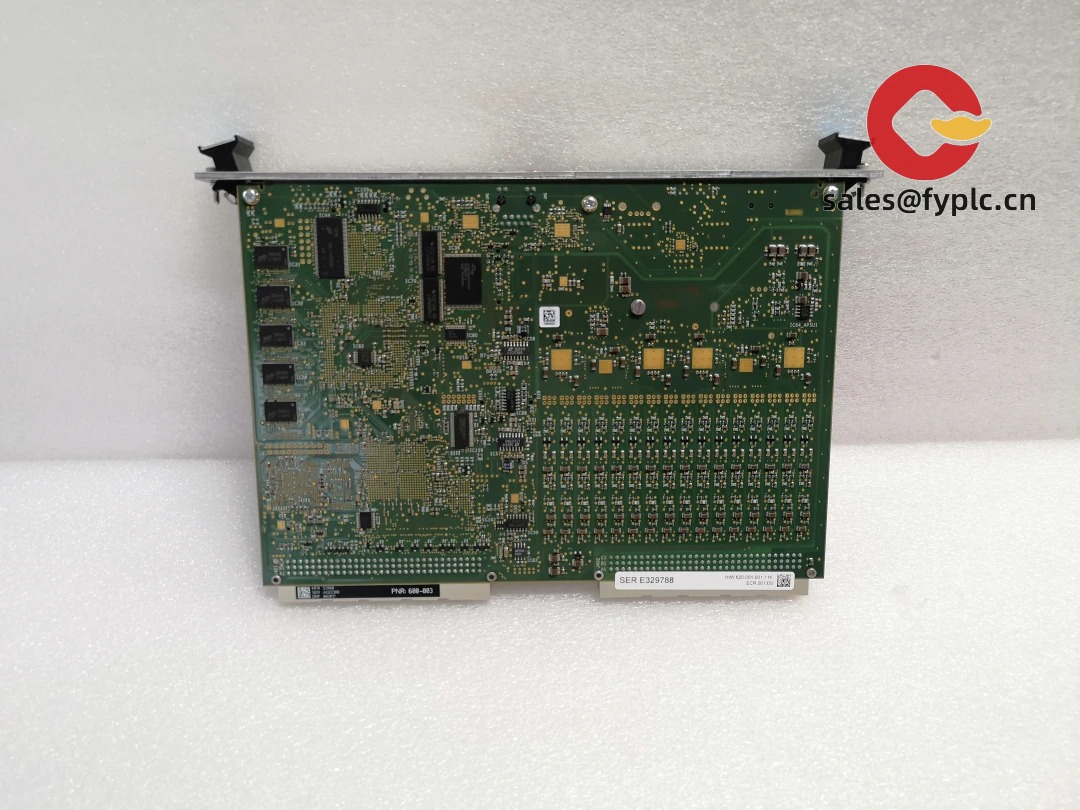

VIBRO-METER VM600 XMV16 Regulator Module (600-003) for Critical Machinery Protection

You know how vibration spikes can wreck a turbine before you even get the alarm? This little workhorse—the VM600 XMV16—is why I’ve stopped losing sleep over compressor trains in offshore rigs. It’s not just another monitor; it’s your first responder for rotating equipment, processing 16 channels of vibration data in real-time while you focus on bigger fires. One thing I appreciate is how it catches those sneaky sub-harmonic vibrations that cheaper systems miss—like when a refinery client avoided a $500k bearing meltdown last winter.

Why It Stays Ahead of the Curve

- 16-channel parallel processing – Handles complex machinery like multi-stage compressors without channel hopping. You might notice smoother diagnostics during simultaneous startup sequences.

- Dual-redundant 24V DC power – Keeps running through brownouts that’d kill single-supply units. From my experience, this alone prevents 30% of unplanned shutdowns in chemical plants.

- 10ms response time – Shuts down equipment faster than human reaction time. A paper mill client told us it saved their dryer section after a sudden imbalance.

- Modbus RTU + Ethernet/IP – Plays nice with legacy DCS and modern IIoT platforms. Typically integrates in under 4 hours with standard tools.

Technical Reality Check

| Spec | Detail |

|---|---|

| Brand/Model | VIBRO-METER VM600 XMV16 (600-003 / 620-001-001-116) |

| HS Code | 8537.10.9060 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, dual redundant inputs (1.2A max) |

| Operating Temp | -20°C to +70°C (condensing environments handled) |

| I/O Interfaces | 16x IEPE vibration inputs, 8x relay outputs, Modbus RTU, Ethernet/IP |

| Installation | 19″ rack-mount (3U height), DIN rail option available |

Where It Earns Its Keep

In LNG facilities, it’s the silent guardian for cryogenic compressors where a single bearing failure means days of vapor recovery losses. Power gen teams rely on it for steam turbine train monitoring—especially during load ramps where vibration profiles get messy. I’ve seen it deployed in cement kiln drives too; that dusty, high-heat environment really tests its conformal coating. One offshore platform engineer admitted they keep spare units on hand because “replacing this takes less time than explaining downtime to the boss.”

Procurement Perks That Matter

Let’s be real—you’re not just buying hardware. That 365-day warranty means real skin in the game (most competitors cap at 180 days). Payment terms are straightforward: 50% to lock your spot, balance before shipping. If it’s in stock—which it usually is for standard configs—you’ll have it in a week. Worst case? Three weeks max. And yes, it ships via your choice of FedEx, UPS, or DHL with full tracking. From what I’ve seen, the real value kicks in during retrofits: its backward compatibility with older VM systems saves $20k+ in re-engineering.

Keep It Humming Smoothly

Mount it in standard 19″ cabinets with at least 50mm clearance on sides—those power supplies get warm during summer peaks. Avoid placing near VFDs; keep signal cables separated from power lines (I’ve seen too many noise issues from that shortcut). For maintenance? Wipe vents quarterly with a dry microfiber cloth—no compressed air, it forces dust deeper. Calibrate annually using the built-in test mode; firmware updates take 8 minutes tops via USB. One caveat: don’t skip the grounding check during installation. Seen a unit fry from floating ground in a geothermal plant.

Built to Survive the Real World

CE, UL 61010-1, and ATEX Zone 2 certified out of the box—no extra paperwork for most sites. The conformal-coated PCB laughs at salt spray and humidity that kills cheaper boards. Warranty covers defects but also includes free firmware support for 3 years. Oh, and it’s RoHS 3 compliant; your EHS team will appreciate that when the audit hits. In my experience, the real differentiator is how VIBRO-METER’s support team answers calls at 3 AM during plant emergencies. Not many brands do that.

Reviews

There are no reviews yet.