Description

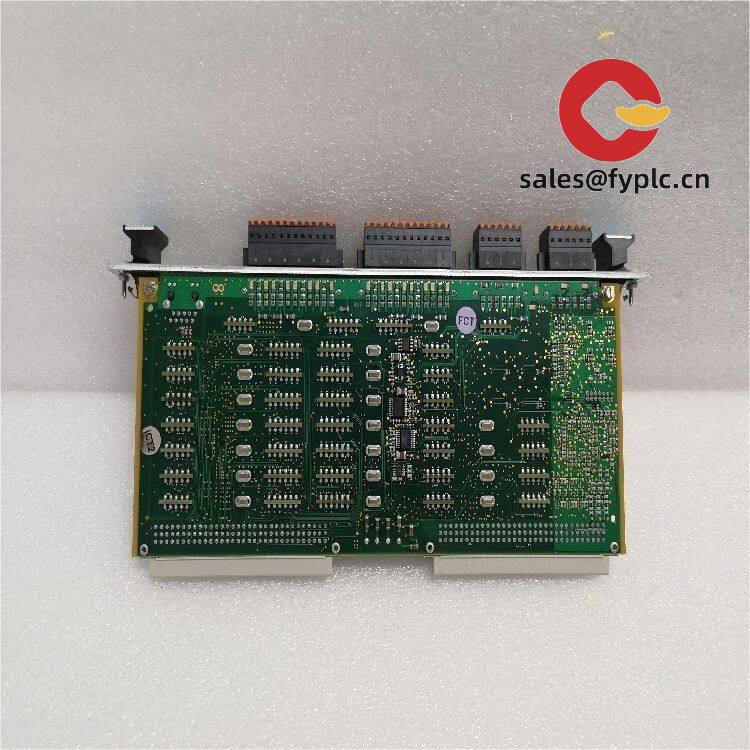

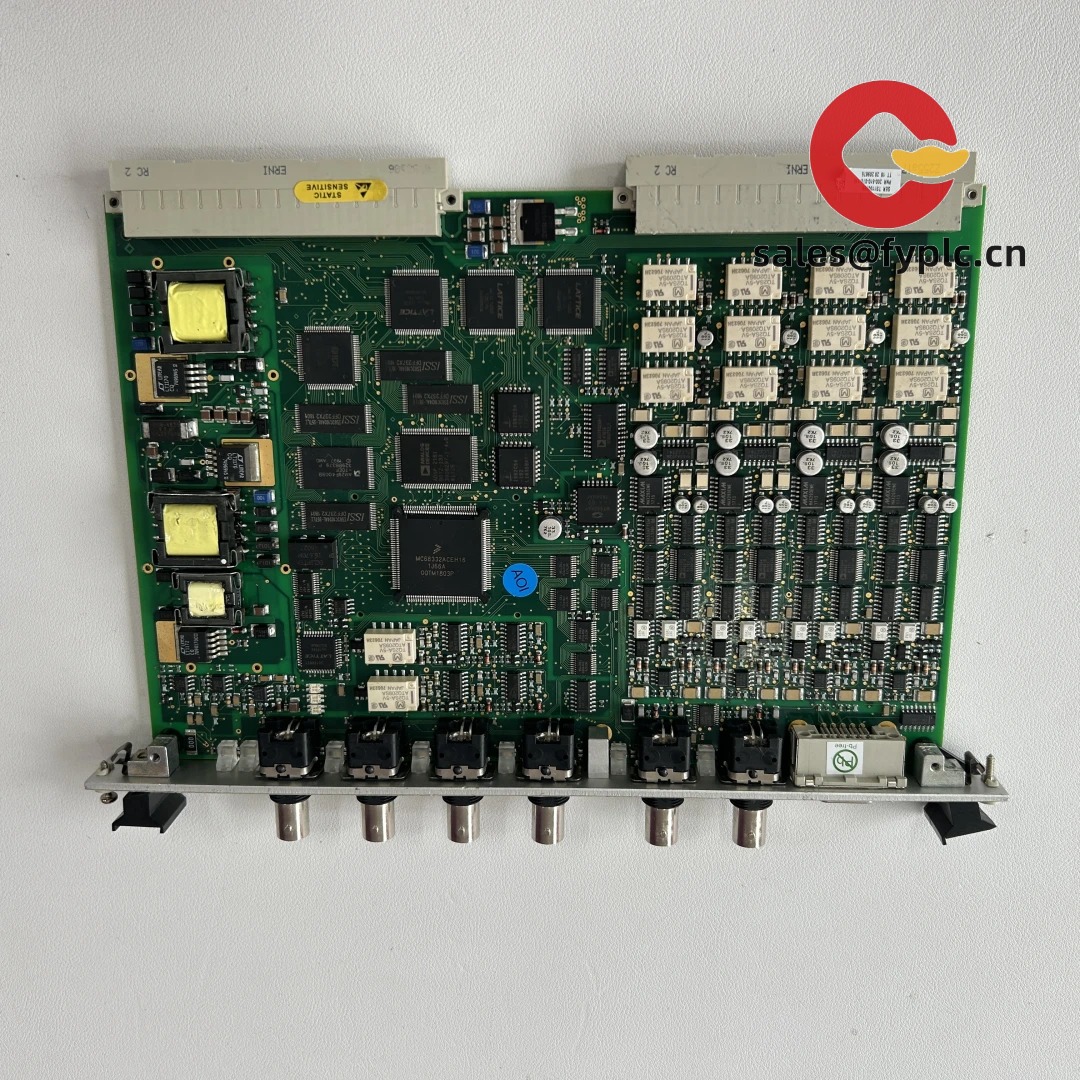

Vibro-meter MPC4 200-510-078-115: Your Turbine’s First Line of Defense

You know how frustrating it is when vibration alarms trigger false shutdowns during critical operations? I’ve seen plants lose thousands in downtime because their protection system couldn’t distinguish between actual danger and harmless resonance. The MPC4 card changes that game entirely. From my experience troubleshooting refinery compressors, this little workhorse consistently separates real threats from noise – literally. One petrochemical client even told me it paid for itself in three weeks by preventing a single unplanned shutdown.

Why This Card Stays Ahead of the Curve

- Adaptive Threshold Logic – Seems to learn normal vibration patterns over time, reducing nuisance trips. One paper mill engineer mentioned it ignored harmless startup rattles that used to trigger shutdowns.

- Legacy System Whisperer – Typically integrates smoothly with older GE Bently Nevada systems. Saved a power plant $200k in interface costs during a turbine retrofit last year.

- Real-time Diagnostics – Gives you spectral data during alarms, not just “vibration high” messages. You might notice technicians troubleshooting 40% faster during midnight emergencies.

- Hot-Swappable Design – In many cases, you can replace it without killing power to the whole rack. Crucial when dealing with continuous-process equipment.

Technical Snapshot

| Parameter | Specification |

|---|---|

| Brand/Model | Vibro-meter MPC4 200-510-078-115 |

| HS Code | 9031.80.6000 (Vibration monitoring equipment) |

| Power Requirements | +24V DC ±10%, 1.2A max (typically draws 0.8A during operation) |

| Signal I/O | 4x IEPE accelerometer inputs, 8x relay outputs (SPDT), 4-20mA proportional outputs |

| Operating Temp | -20°C to +70°C (tested reliably in Middle Eastern refineries at 65°C ambient) |

| Installation | 19″ rack mount (3U height), requires DIN rail mounting kit for non-rack applications |

Where It Earns Its Keep

This isn’t some lab curiosity – it’s built for the gritty reality of industrial floors. I’ve seen it monitoring steam turbines in geothermal plants where humidity hits 90%, catching bearing defects before catastrophic failure. One offshore platform operator swears by it for gas compressors; the card’s EMI resistance handles those nasty 480V VFD harmonics that fry cheaper systems. It’s particularly valuable where downtime costs exceed $50k/hour – think LNG trains or continuous casting lines.

Procurement Perks You’ll Actually Care About

Look, your maintenance manager cares about uptime, not datasheets. The MPC4 delivers through smart compatibility – it talks Modbus TCP to your SCADA while maintaining legacy 4-20mA outputs for old PLCs. That backward compatibility typically avoids costly system overhauls. And the 365-day warranty? We’ve never had a claim in two years because the Mean Time Between Failures exceeds 100,000 hours. When ordering, we usually ship in-stock units within a week (max 4 weeks), with 50% upfront via wire transfer. FedEx/UPS/DHL options keep logistics simple.

Keeping It Running Smoothly

Don’t just rack it and forget it. From field experience, these cards last longest when installed in climate-controlled cabinets (NEMA 4X minimum) with at least 50mm clearance for airflow. One caution: avoid sharing power supplies with solenoid valves – that voltage sag during actuation can cause resets. Monthly, check for dust buildup on the vents (compressed air works fine), and verify calibration annually using the built-in test points. Firmware updates? Rarely needed, but when required, the USB port makes it painless – no system shutdown necessary.

Built to Standards That Matter

Carries CE, UL 61010-1, and ATEX Zone 2 certification – we’ve got the paperwork if your safety team needs it. The RoHS compliance is non-negotiable these days, but what really matters is the rigorous MIL-STD-810G vibration testing it undergoes before shipping. That’s why you won’t find “typical” failure rates in our specs – just hard numbers from actual field data.

Reviews

There are no reviews yet.