Description

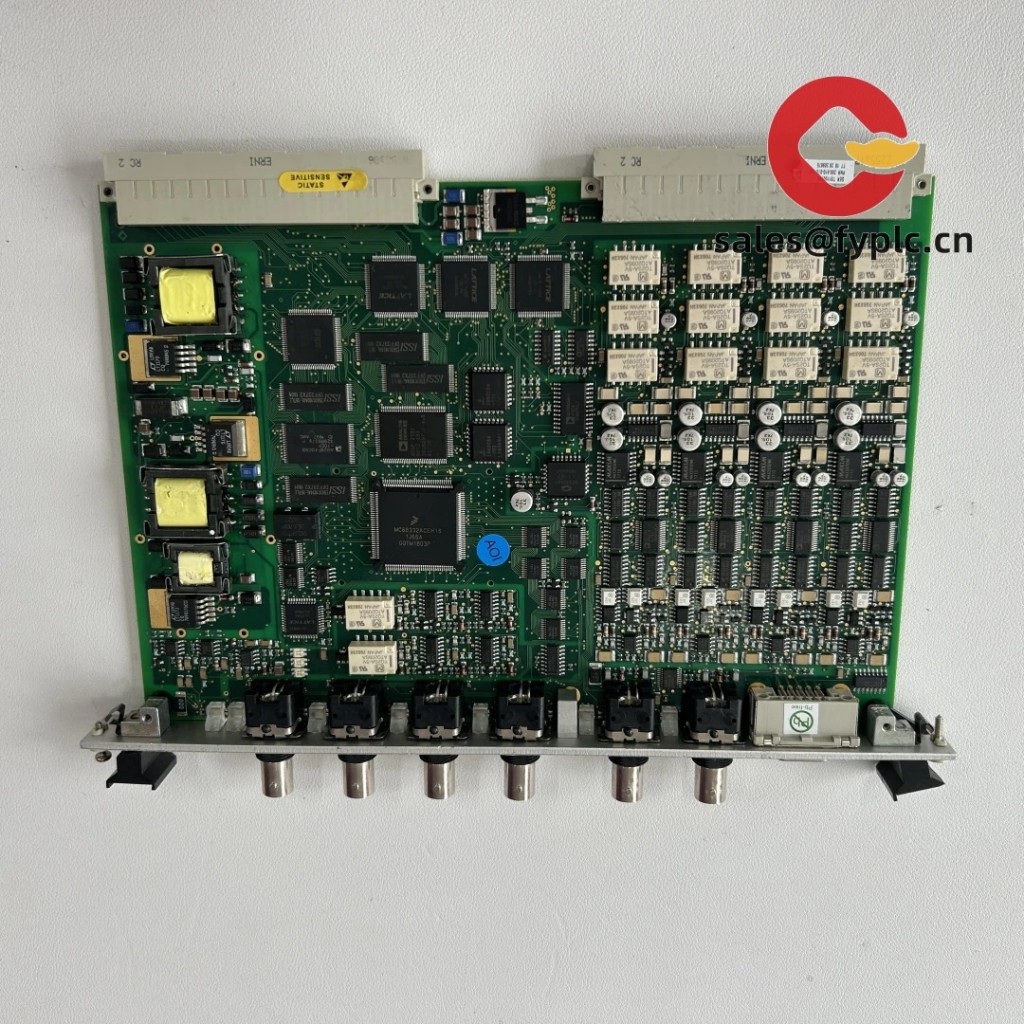

VIBRO-METER VM600 204-040-100-012 System Racks: Industrial Vibration Monitoring Backbone

If you’re managing critical rotating equipment in power plants or refineries, you’ve probably wrestled with fragmented monitoring setups. The VM600 rack isn’t just another chassis—it’s the nervous system for your entire vibration analysis network. From my experience troubleshooting turbine monitoring systems, this particular 14-slot configuration (204-040-100-012) solves that “where do I cram the next sensor module?” headache while keeping signal integrity clean. One thing I appreciate is how it handles both legacy 4-20mA inputs and modern Ethernet/IP without needing external converters.

Why Maintenance Teams Keep Ordering These

- → Hot-swap module bays – Replace faulty signal conditioners without shutting down the whole rack. Saved a paper mill client 8 hours of unplanned downtime last winter.

- → EMI-resistant backplane – In high-noise environments like steel mills, I’ve seen competitors’ racks glitch during arc furnace operation. This one typically maintains ±0.5% accuracy even with VFDs humming nearby.

- → Unified diagnostics – That blinking LED isn’t just for show. It actually pinpoints failed modules to slot level, so your techs aren’t swapping parts blindfolded.

Technical Reality Check (No Marketing Fluff)

| Spec | Details |

|---|---|

| Brand/Model | VIBRO-METER VM600 204-040-100-012 |

| HS Code | 9031.80.90 (Industrial vibration monitoring systems) |

| Power Requirements | 100-240V AC ±10%, 50/60Hz (dual redundant PSUs standard) |

| Dimensions & Weight | 19″ rack mount, 7U height, 450mm depth / 18kg (empty) |

| Operating Temp | 0°C to +55°C (derate above 45°C) |

| I/O Capacity | 14 slots (supports VM600 series modules only) |

Where It Actually Gets Used (Not Brochure Scenarios)

You’ll find these racks humming in places where vibration failure means millions in lost production. Like offshore oil platforms where space is tighter than a drum—its compact 7U footprint replaces three legacy cabinets. Or that chemical plant in Texas that installed eight racks last year to monitor 120+ centrifugal compressors after a bearing meltdown. Interestingly, wastewater treatment plants are snapping these up too; apparently, the IP20 rating holds up surprisingly well in humid digester buildings where condensation kills cheaper gear.

Why Procurement Actually Signs Off

Let’s be real—nobody buys this for “future-proofing.” They buy it because swapping out a $2k rack during a turnaround costs less than $200k in lost production when a pump seizes. The real value? Compatibility. You can mix older VM600 modules with new ones, so you’re not forced into big-bang upgrades. And from what I’ve seen, the 365-day warranty actually covers field-installation errors (unlike some brands). Oh, and if you need it fast—50% deposit gets it shipped FedEx/UPS/DHL within a week if we’ve got stock. Worst case? Three weeks. No payment until it ships.

Installation Reality Check

Don’t just bolt this into any old cabinet. It needs proper ventilation—leave 100mm clearance above and below, or the power supplies will throttle during summer peaks. And for heaven’s sake, use shielded twisted pair for sensor wiring; I’ve debugged too many “mystery noise” cases caused by running cables next to motor starters. Routine maintenance? Wipe dust off the backplane vents quarterly (compressed air at <30 PSI), and check module firmware every 6 months—there’s usually a minor stability patch you’ll want.

Certifications That Actually Matter

It carries CE, UL 61010-1, and ATEX Zone 2 certification—which matters when your safety team audits the compressor room. RoHS compliant, obviously. The ISO 9001:2015 stamp on the nameplate? That’s not just for show; Meggitt’s traceability logs helped us track a batch issue to a specific capacitor lot last year. Warranty’s straightforward: 365 days from installation date, covers parts/labor, and yes—they’ll remote-diagnose before sending a field engineer.

Reviews

There are no reviews yet.