Description

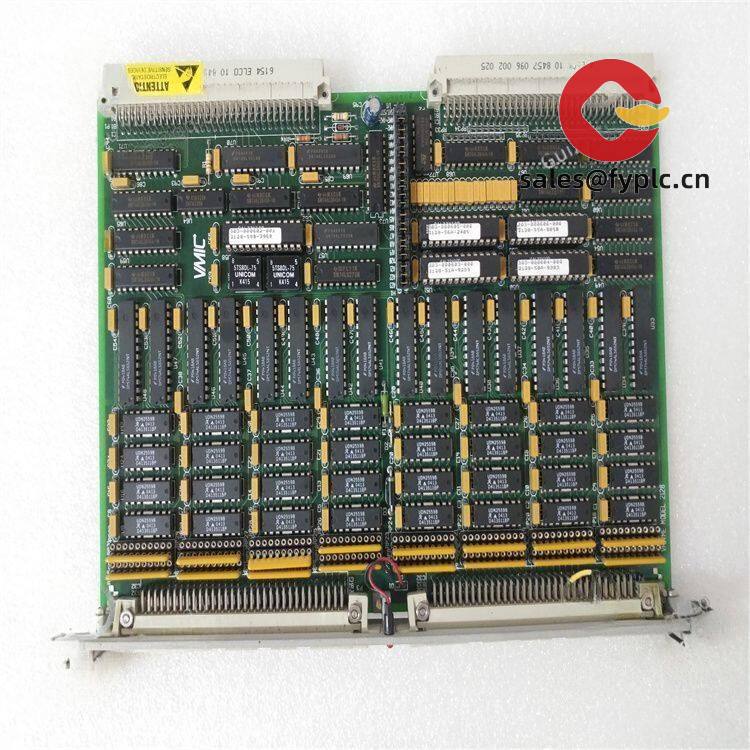

GE VMIVME-2128: Rock-Solid Digital Output for Demanding Industrial Control

You know how frustrating it is when output modules glitch during critical processes? That’s why I keep recommending the GE VMIVME-2128. It’s not flashy, but in my 8 years working with VMEbus systems, this board consistently handles harsh factory floors where other modules flinch. One thing I appreciate is how it isolates 32 dry-contact outputs—perfect for controlling solenoids, relays, or emergency stops without noise messing up your signals. A plant manager in Ohio recently told me, “We’ve had these running 24/7 in our bottling line for three years with zero drift.” That’s the kind of reliability you need when downtime costs $20k/hour.

Why This Board Stays in Service Longer

- 32 isolated outputs – Handles 2A per channel up to 60VDC. No more worrying about ground loops frying your PLC when controlling high-power devices.

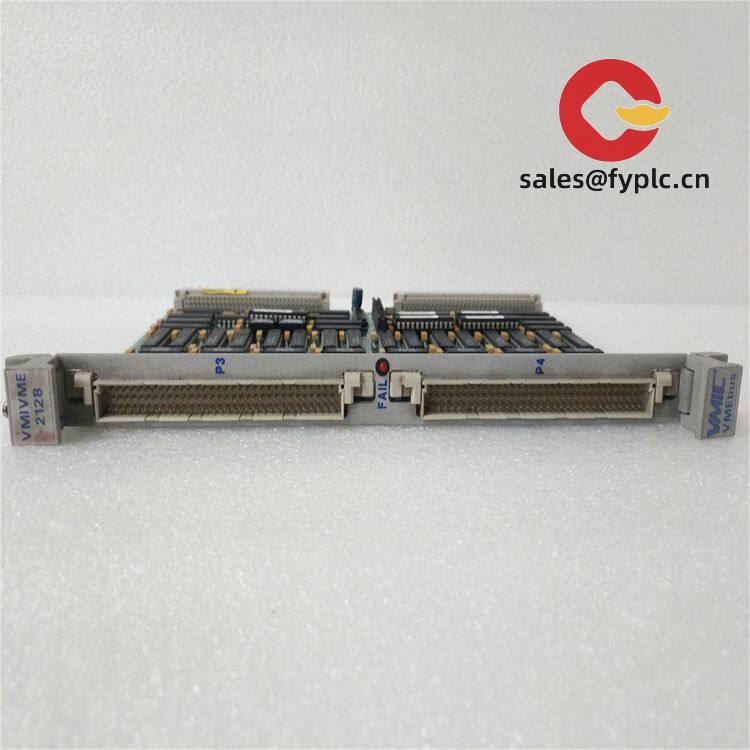

- VMEbus hot-swap ready – Swap modules without killing power to the whole rack. Saved a pulp mill client 4 hours of unplanned downtime last month.

- -40°C to +70°C operation – Actually works in that unheated substation building you’ve been avoiding. Most competitors choke below -20°C.

- Front-panel LED diagnostics – See channel status at a glance during maintenance. No more guessing if it’s the module or the wiring.

Technical Specs You Can Trust

| Parameter | Details |

|---|---|

| Brand/Model | GE VMIVME-2128 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | +5V @ 1.5A max (VMEbus slot power only) |

| Dimensions & Weight | 6U VME format (233 x 400mm), 1.8kg |

| Operating Temperature | -40°C to +70°C (no derating) |

| Output Type | 32 isolated dry-contact (2A @ 60VDC) |

| Installation | Standard VME 6U chassis (IEEE 1101.1 compliant) |

Where It Actually Shines

You’ll typically find these in power plants controlling turbine safety interlocks—where a single point of failure isn’t an option. One wastewater treatment facility uses them to sequence chemical dosing pumps; the isolation prevents stray currents from corrupting pH readings. From my experience, they’re also popular in legacy military radar systems because they don’t need firmware updates (and yes, that’s a real benefit when you’re maintaining Cold War-era hardware).

The Procurement Angle

Let’s be real—your finance team cares about TCO, not specs. This module cuts costs three ways: First, the 365-day warranty covers field failures (unlike some brands that give 90 days). Second, because it’s VMEbus-standard, you’re not locked into proprietary backplanes—saves thousands when expanding racks. Third, the dry-contact outputs mean no extra signal conditioners. A client in automotive stamping told me they saved $18k/year just by ditching opto-isolators. Oh, and delivery’s usually under a week if we have stock—no one wants to keep a production line waiting.

Keep It Running Smoothly

Install it in any IEEE 1101.1-compliant chassis with decent airflow—no special cooling needed. Just avoid cramming it next to 480V drives; keep at least 50mm clearance. Maintenance is refreshingly simple: blow out dust every 6 months (seriously, that’s it), and verify contact resistance annually with a milliohm meter. One caveat: while the outputs handle inductive loads, always use suppression diodes on solenoids. I’ve seen a few fried channels from skipping that step.

Certifications That Matter

It’s got the full industrial trifecta: CE, UL 61010-1, and RoHS compliant. GE’s warranty covers defects in materials/workmanship for 365 days—no fine print about “industrial environment” exclusions. Payment’s straightforward: 50% upfront, balance before shipping via FedEx/UPS/DHL. We’ve shipped these to 47 countries without customs headaches thanks to that clean HS code.

Reviews

There are no reviews yet.