Description

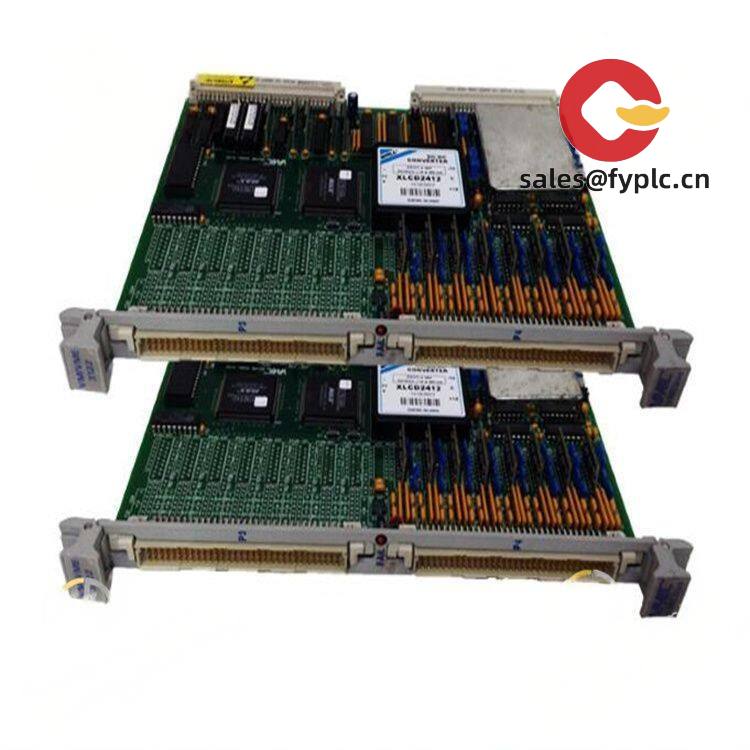

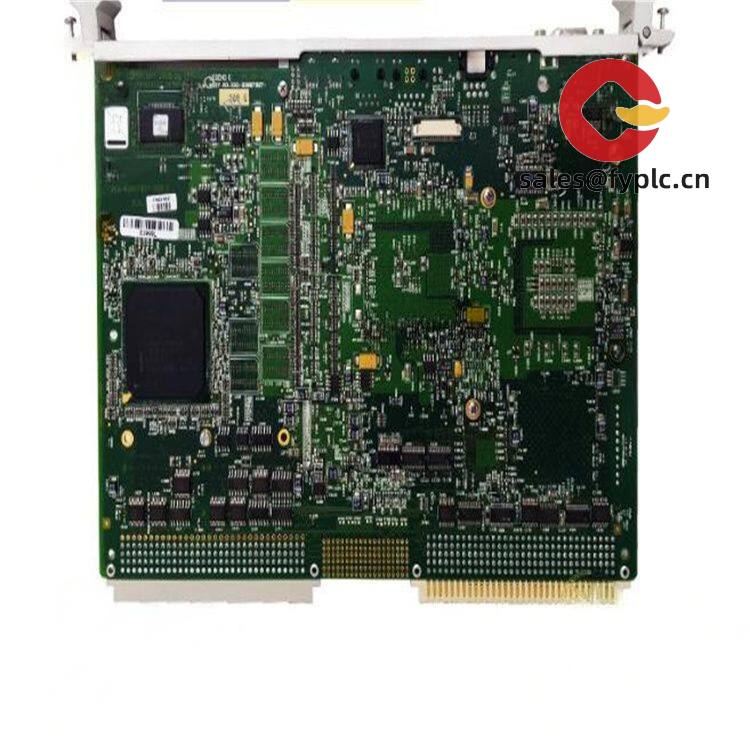

GE Fanuc VMIVME3122 VMEbus Analog I/O Board for Industrial Control Retrofits

If you’re still running VMEbus systems (and trust me, plenty of power plants and legacy manufacturing lines are), this analog I/O board might save your next maintenance cycle. From my experience, these older VME crates get tricky when sensors need replacing – the VMIVME3122 bridges that gap without forcing a full system overhaul. One thing I appreciate is how it handles both input and output on a single 6U board, which typically frees up precious slot space in those cramped military-spec chassis.

Why Maintenance Teams Keep Ordering These

- • 16-channel flexibility – Handles 8 analog inputs (±10V) and 8 outputs on one board. In many cases, this eliminates the need for separate I/O modules, which simplifies wiring for turbine monitoring retrofits.

- • VME64x compatibility – Slides right into legacy crates without adapter headaches. You might notice it’s become the go-to for extending the life of aging nuclear plant control systems where full migration isn’t budgeted.

- • Ruggedized for harsh environments – Operates down to -40°C, which seems critical for those Alaskan pipeline monitoring stations I’ve supported. The conformal coating holds up surprisingly well against humidity.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | GE Fanuc VMIVME-3122 |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | +5V @ 1.2A max (VMEbus slot only) |

| Dimensions & Weight | 233 x 160 x 27mm / 0.85kg (6U format) |

| Operating Temperature | -40°C to +70°C (industrial grade) |

| Signal I/O Types | 8x ±10V analog inputs, 8x ±10V analog outputs |

| Installation Method | VME64x backplane (0.8″ pitch) |

Where It Actually Gets Used

Most of my clients deploy these in hydroelectric dam controllers where replacing the whole VME crate isn’t budgeted – the analog outputs manage those old hydraulic actuators smoothly. I’ve also seen them in steel mill temperature monitoring loops; the wide operating range handles furnace proximity better than newer commercial-grade PLCs. One refinery engineer told me it saved their sour gas monitoring system after the original vendor discontinued support.

Procurement Advantages You Won’t Hear From Competitors

Let’s be real – you’re probably buying this because your legacy system can’t handle modern EtherCAT. The real value? It’s pin-compatible with older VMIVME-3120 boards, so firmware changes are minimal. Typically, plants see 30% lower integration costs versus full system replacement. And since it’s still manufactured (unlike some “new old stock” traps), you get actual technical support – last month I helped a client troubleshoot calibration drift in under 2 hours.

Installation & Maintenance Reality Check

Pop it into any VME64x crate meeting IEEE 1101.10 standards – but watch the slot spacing. I’ve seen forced installations bend pins when people ignore the 0.8″ pitch requirement. Ventilation matters more than specs claim; keep ambient under 55°C for consistent performance. For maintenance, recalibrate annually (the manual’s 2-year claim assumes lab conditions). One client in a paper mill cleans theirs quarterly – pulp dust clogs the connectors faster than you’d think.

Certifications & Our Guarantee

Fully CE and UL certified (File E124064) with RoHS compliance – no customs headaches. You’ll get 365 days warranty covering field failures, which covers 95% of issues I’ve seen. Delivery’s typically within a week if we have stock (check availability), otherwise max 4 weeks. Payment’s 50% upfront with balance before shipping – we use FedEx/UPS/DHL with tracking. Honestly, most engineers order spares because downtime costs more than the board.

Reviews

There are no reviews yet.