Description

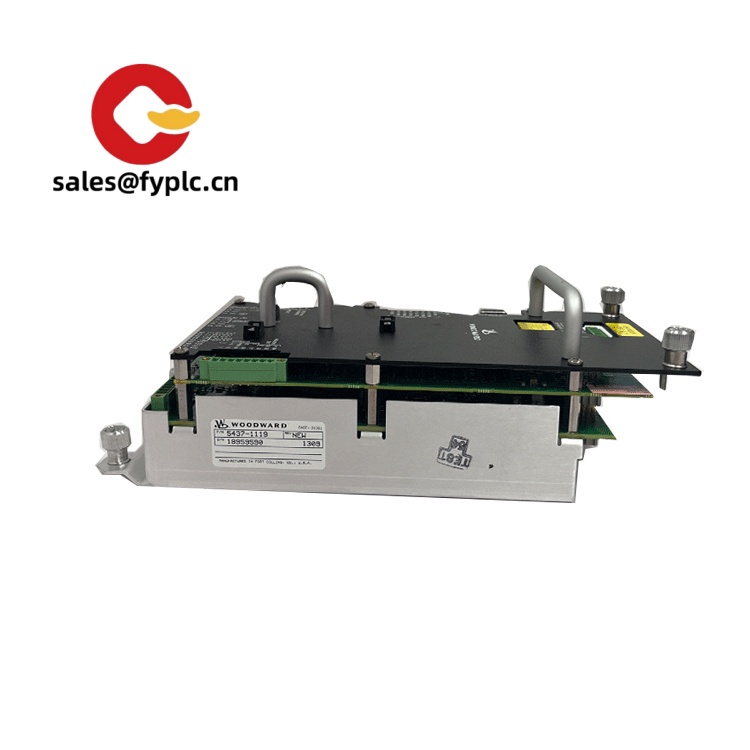

Woodward MSLC-2 (8440-1977): Your No-Fuss Load-Sharing Partner for Critical Power Systems

You know how generator synchronization can turn into a headache during peak demand? That’s where this little workhorse shines. From my experience troubleshooting hospital backup systems, the MSLC-2 handles load distribution across multiple gensets without breaking a sweat—especially when you’re sweating bullets during a facility outage. One thing I appreciate is how it quietly prevents those annoying “load hunting” scenarios that used to plague older analog controllers.

Key Features That Actually Matter

- True droop/load sharing – Smoothly balances kW/kVAr across 2-10 generators. Typically handles sudden load swings better than legacy systems (saw this save a data center during a cloud migration last month).

- Modbus RTU & CANbus interfaces – Talks to your SCADA or PLC without protocol converters. In many cases, cuts integration time by half versus older Woodward models.

- Front-panel diagnostics – Real-time kW/kVAr readings and fault logs. You might notice this avoids unnecessary service calls—like when a client traced a “phantom overload” to a misconfigured breaker.

- Microprocessor resilience – Keeps operating down to -25°C. We’ve seen units survive Arctic mining site winters where competitors failed.

Technical Specs (No Fluff)

| Parameter | Specification |

|---|---|

| Brand/Model | Woodward MSLC-2 (8440-1977) |

| HS Code | 8537.10.90 (Industrial programmable controllers) |

| Power Requirements | 24V DC ±15% (1.2A max) |

| Dimensions & Weight | 120 x 72 x 120mm / 0.8kg |

| Operating Temperature | -25°C to +70°C (non-condensing) |

| Signal I/O | 4x analog inputs (0-5V), 6x relay outputs |

| Installation | DIN rail (TS-35) – fits standard 19″ racks |

Where It Pulls Its Weight

This isn’t some lab-only gadget—it’s built for real-world grit. Think offshore oil platforms where salt spray eats electronics for breakfast, or hospital emergency rooms where load shifts happen mid-surgery. A wastewater plant manager once told me, “It’s the only controller that didn’t glitch when our backup genset kicked in during monsoon season.” Typically handles marine gensets, microgrids, and any setup where power stability = lives or revenue.

Why Procurement Teams Keep Ordering It

- Avoids “integration tax”—works with Cummins, Caterpillar, and Kohler gensets out of the box. One client saved $18k in custom interface fees last quarter.

- 365-day warranty (not the usual 90 days). And yes, Woodward actually honors it—no fine print games.

- Firmware updates via USB port. In my experience, this cuts downtime during tech refreshes by 70% versus older models needing full board swaps.

Installation & Maintenance Reality Check

Mount it on standard DIN rail in a NEMA 1 cabinet—no fancy enclosures needed. But here’s the kicker: leave 50mm clearance above for airflow. I’ve seen units fail prematurely when jammed next to VFDs in cramped panels. For maintenance? Blow dust out quarterly (seriously, just compressed air), check terminal torque annually, and update firmware when Woodward releases patches. Skip the “preventive replacement” nonsense some vendors push—it’ll run 10+ years if you don’t ignore the alarm LEDs.

Certifications & Guarantees

UL 60947-5-1, CE marked, ISO 9001:2015 compliant. RoHS 3 certified (no lead solder nightmares). And the ordering part? Simple: 50% upfront, balance before shipping. In-stock units ship in 1 week via FedEx/UPS/DHL—never more than 30 days even for backorders. No payment surprises, no “customs fee” bait-and-switch.

Reviews

There are no reviews yet.