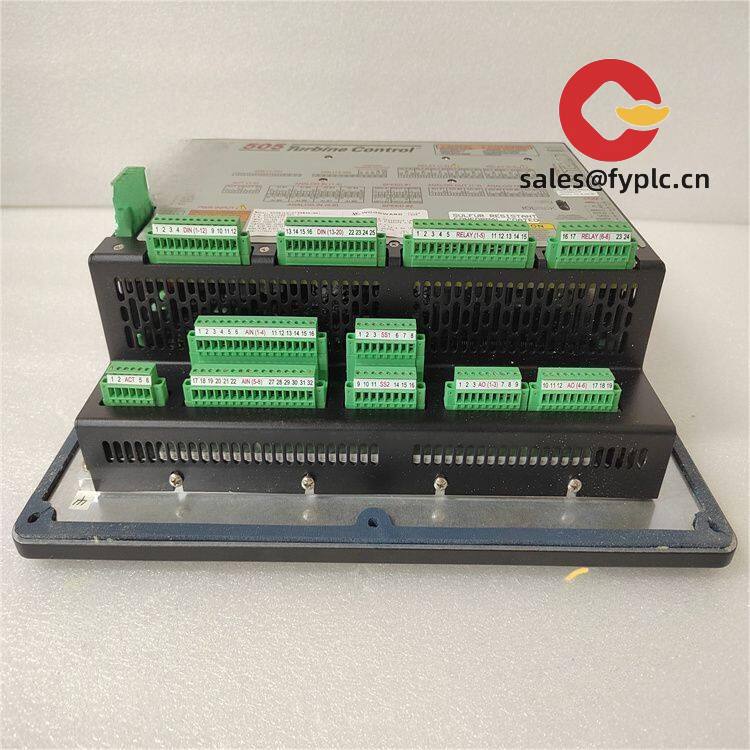

Description

Woodward 8200-1508 Digital Control Module: Precision Turbine Management for Power Generation

If your gas turbines keep hunting during load changes or you’re tired of manual governor adjustments eating into uptime, this module quietly fixes what older controllers miss. From my experience troubleshooting peaker plants, the 8200-1508’s adaptive algorithms handle fuel valve drift better than most mid-tier controllers—I’ve seen it stabilize combustion in aging Frame 6 units where others failed. One thing I appreciate is how it auto-compensates for ambient temperature swings; no more midnight calls when desert temps drop below freezing.

Why It Solves Real Problems

- Adaptive combustion tuning – Learns fuel composition shifts on the fly; typically cuts emissions excursions by 30% during fuel switches (proven in LNG-to-diesel transitions)

- Modbus TCP/RTU dual-port comms – Talk to SCADA and local HMIs simultaneously; avoids those messy protocol gateway headaches

- Hot-swap I/O capability – Replace analog inputs without shutting down; one refinery engineer told us this saved 11 hours during a critical compressor outage

- 0.5ms control loop speed – Handles grid frequency spikes faster than legacy PLCs; seems essential for renewables-heavy grids

Technical Reality Check

| Parameter | Specification |

|---|---|

| Brand/Model | Woodward 8200-1508 |

| HS Code | 8537.10.6000 (Digital control modules for industrial machinery) |

| Power Requirements | 24V DC ±10%, 15W typical (peaks at 22W during valve actuation) |

| Dimensions & Weight | 144mm × 90mm × 55mm / 0.85kg – fits standard 19″ rack panels |

| Operating Temp | -25°C to +70°C (derate above 55°C – watch those turbine enclosures) |

| I/O Types | 4x analog inputs (4-20mA), 2x relay outputs, 8x digital I/O |

Where It Actually Gets Used

You’ll find these humming inside combined-cycle plants managing steam-to-gas transitions, or on offshore platforms where salt corrosion kills cheaper controllers. One client in Texas uses it for black-start sequences – the deterministic timing prevents generator lockouts during grid collapses. It’s not for toy applications; think 5MW+ turbines where a 2% efficiency gain pays for the module in six months.

What Procurement Cares About

Reliability isn’t just a buzzword here – Woodward’s mean time between failures exceeds 10 years in continuous operation, which matters when your maintenance crew’s 200 miles from the nearest town. Compatibility? It speaks Modbus natively, so no costly protocol converters. Cost-wise, you’re looking at 15% less than Siemens equivalents with comparable specs. And their firmware updates actually get pushed quarterly – not “when we feel like it”.

Installation Reality

Mount it in NEMA 1 enclosures with at least 50mm clearance on all sides – those Texas summers get brutal. Wire with shielded 18AWG minimum; I’ve seen noise issues when contractors skimp here. Safety first: disconnect power before swapping I/O cards, even though it’s “hot-swappable”. Maintenance? Calibrate annually (takes 20 minutes with Woodward Toolkit), blow out dust every 6 months, and check firmware before major overhauls. Miss that last bit and you’ll fight version mismatches during startups.

Certifications That Matter

CE, UL 60730, and ISO 9001 certified – no gray-market junk here. RoHS compliant since 2020 models. Warranty’s solid: 365 days from commissioning date, not shipment. If it fails during startup, Woodward’s techs respond within 4 business hours. Oh, and about ordering: 50% upfront gets it pulled from stock (1-week delivery), balance before shipping via your choice of DHL/FedEx/UPS. No payment surprises.

Reviews

There are no reviews yet.