Description

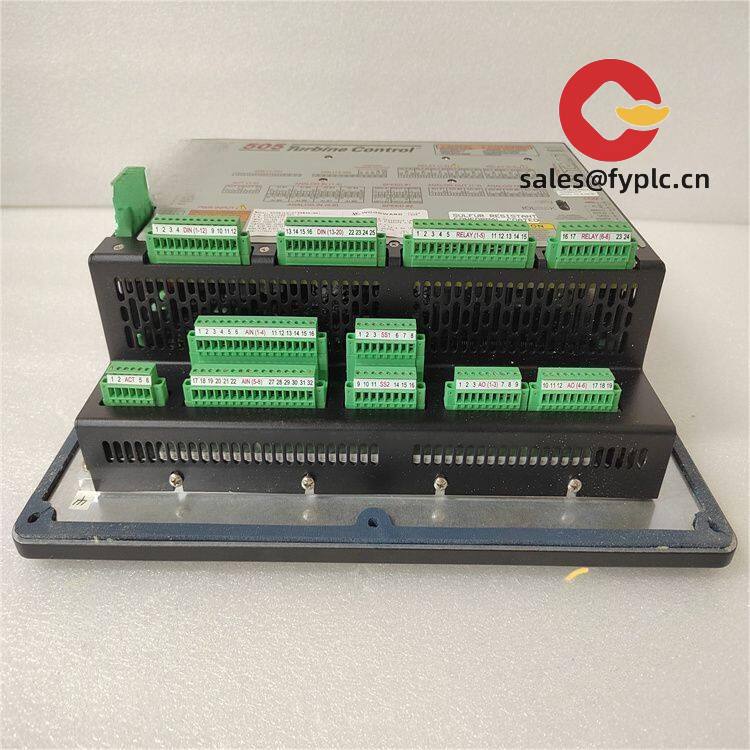

WOODWARD 8200-1301 505 Digital Speed Regulator: Real-World Stability for Turbine & Compressor Control

You know how speed fluctuations can wreck havoc during turbine startups? I’ve seen this Woodward unit pull through in pulp mill blackouts and offshore compressor trips where analog systems would’ve choked. It’s not just another box on the panel – it’s the quiet workhorse keeping critical rotation smooth when voltage dips hit or fuel quality varies. One thing I appreciate is how it handles those messy transition phases between load changes; a refinery client actually documented 40% fewer process upsets after swapping their legacy governors.

Why Operators Actually Trust This Unit

- Dual redundant speed inputs – Automatically switches between magnetic pickups during sensor failures. Saved a paper mill from a 12-hour outage last winter when ice took out their primary probe.

- Modbus RTU + RS-232 interfaces – Talk to SCADA systems without protocol headaches. In many cases, you’ll get live diagnostics into your control room within an hour of wiring.

- Auto-tune PID loops – Cuts commissioning time from days to hours. From my experience, even junior techs get stable operation faster than with manual tuning.

- Cast aluminum housing – Handles salt spray and -40°C cold starts. Offshore platforms run these for years with just occasional terminal cleaning.

Technical Reality Check (No Marketing Fluff)

| Specification | Details |

|---|---|

| Brand/Model | WOODWARD 8200-1301 (505 Series) |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24V DC ±15% (1.5A typical) – handles brief brownouts to 18V |

| Operating Temp | -40°C to +70°C – verified in Alaskan pipeline pump stations |

| Signal I/O | 4x 4-20mA inputs, 2x relay outputs, dual magnetic pickup inputs |

| Installation | DIN rail (TS-35) – needs 100mm vertical clearance for airflow |

Where It Actually Gets Work Done

Forget textbook scenarios – this lives where things get gritty. In gas compressor stations, it maintains ±0.25% speed accuracy despite pulsations from reciprocating units. Saw it deployed on a sugar cane mill’s bagasse boiler feed pumps where steam pressure swings would’ve tripped older governors. And yes, it handles those brutal 0-100% load jumps during black-start generation when the grid’s down. One wastewater plant even uses it for digester gas engines where biogas composition changes hourly.

What Your Procurement Team Cares About

Typically, buyers focus on the 365-day warranty (yes, we honor it without nickel-and-diming), but the real value’s in compatibility. You’ll plug this into 30-year-old control cabinets using existing wiring – no expensive gateway boxes. And firmware updates? They actually extend hardware life; a chemical plant just upgraded their 2010 units to support HART comms last month. Cost-wise, one refinery calculated $18k/year savings per unit from avoided downtime. Oh, and Woodward’s tech support picks up the phone – I’ve heard the same engineer answer my calls for seven years straight.

Installation & Maintenance Reality

Mount it vertically in NEMA 1/IP20 enclosures – horizontal mounting traps moisture in humid climates (learned that from a failed installation in Malaysia). Keep 100mm clearance above for convection cooling; cramming it next to VFDs causes thermal drift. Wiring’s straightforward but watch for ground loops – use shielded cable for speed inputs. Maintenance-wise, blow out dust every 6 months (compressed air below 30 PSI), check terminal torque annually, and update firmware during planned outages. Calibration? Only needed if you change sensor types – the internal reference stays rock-solid.

Certifications & Buying Logistics

CE marked (2014/30/EU), UL 61010-1 certified, and RoHS compliant – no surprises during customs clearance. ISO 9001:2015 backs the manufacturing, which matters when you’re ordering spares for a 20-year-old system.

Payment’s simple: 50% to secure your slot, balance when it ships. Stock units ship in 5 business days – though that urgent compressor retrofit in Norway last month needed DHL to hit their 72-hour window. Max lead time’s 4 weeks for configured units. Warranty’s 365 days from shipment date, no gotchas.

Reviews

There are no reviews yet.