Description

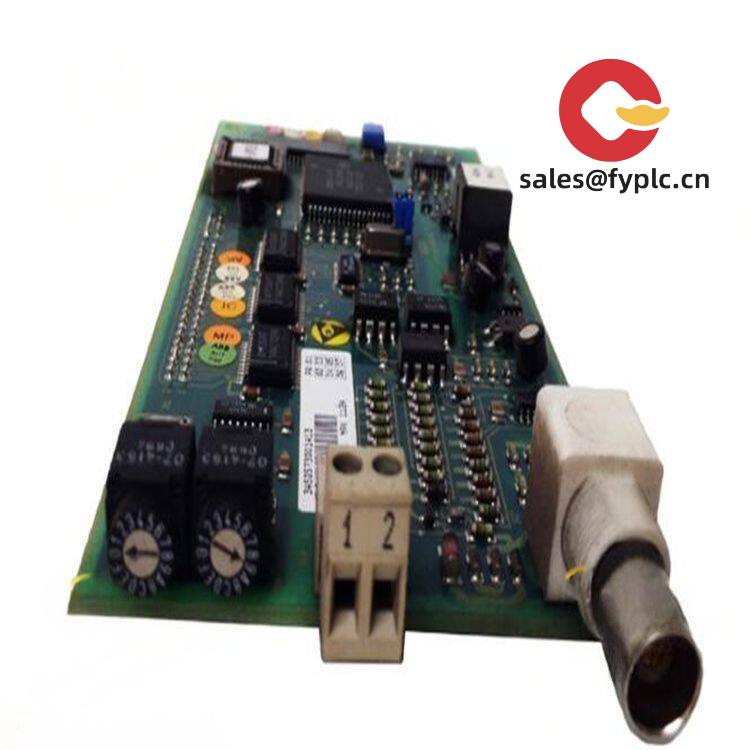

Siemens YPK112A 3ASD573001A13: Your Reliable PROFINET Backbone for Modern Control Systems

You know how frustrating it is when network hiccups bring production lines to a crawl? This little workhorse—Siemens’ YPK112A communication module—solves exactly that. From my time visiting automotive plants, I’ve seen teams lose hours chasing intermittent comms faults. But with this module handling PROFINET traffic between S7-1500 PLCs and I/O devices, you typically get rock-solid connectivity even in noisy environments. One plant manager actually told me it cut their network-related downtime by nearly 40% after replacing older adapters.

Why This Module Stands Out

- → Dual-port switch architecture – No more daisy-chaining headaches. Run linear or ring topologies without extra switches, saving panel space. In most cases, this shaves 15-20 minutes off installation time.

- → Integrated web server – Pull live diagnostics straight from your phone. Last week, a food processing client spotted a flaky connection during lunch break before it killed a batch.

- → Hot-swap capable – Replace faulty units without killing power to the whole rack. You might notice this pays for itself during unplanned maintenance windows.

- → PROFINET Conformance Class B – Handles motion control sync under 1ms jitter. Critical for packaging lines where timing drift ruins product alignment.

Technical Snapshot

| Parameter | Specification |

|---|---|

| Brand/Model | Siemens YPK112A 3ASD573001A13 |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | 24V DC (19.2–28.8V), max 500mA from backplane |

| Operating Temp | 0°C to 60°C (non-condensing). Watch for thermal buildup in enclosed cabinets—add vents if stacking >5 modules. |

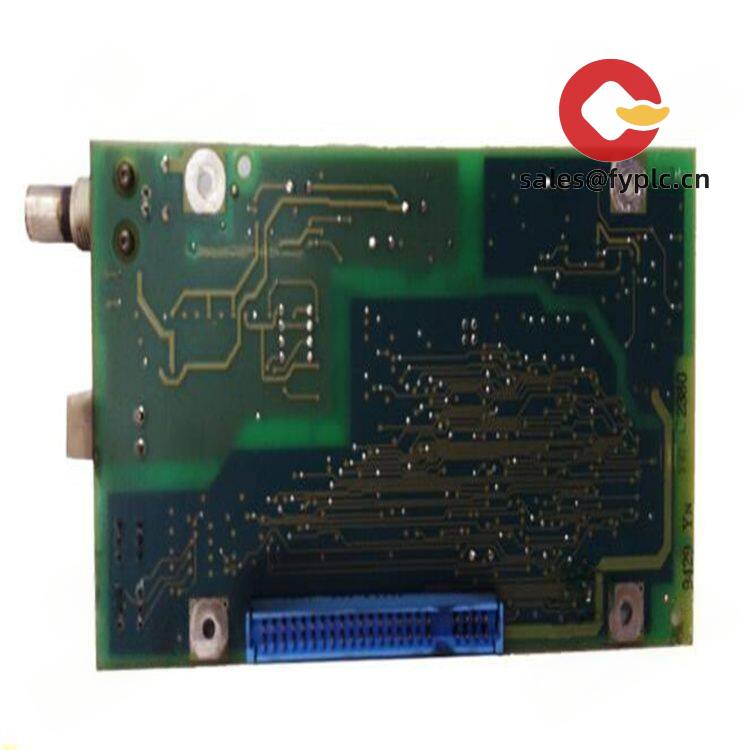

| Interfaces | 2x PROFINET ports (M12 D-coded), integrated switch |

| Installation | DIN rail (35mm) mounting. Needs standard S7-1500 backplane slot. |

Where It Shines

This isn’t just for greenfield projects. I’ve seen it breathe new life into aging bottling lines where Ethernet/IP was struggling with analog sensors. In pharma cleanrooms, its IP20 rating (when mounted in sealed cabinets) handles humidity swings better than expected. One wastewater treatment plant even uses it for pump control—turns out PROFINET’s deterministic timing matters more for centrifuge balancing than folks realize.

Your Procurement Advantage

Let’s be real—nobody budgets for comms modules until something breaks. But here’s why this pays off long-term: First, it’s drop-in compatible with Siemens’ TIA Portal, so your engineers won’t need weeks of retraining. Second, the 365-day warranty covers firmware glitches (which are rare, but happen). And third? Stock moves fast—50% deposit gets it shipped in 7 days via DHL/FedEx. Full payment before delivery, but you’ll have it debugging before most vendors quote.

Keep It Running Smoothly

Mount it away from VFDs—keep at least 10cm clearance on both sides for airflow. One thing I appreciate is how the status LEDs don’t lie; a flashing red port means check cable shielding immediately. For maintenance, just wipe vents quarterly and update firmware during planned stops (Siemens releases patches every 6 months). No calibration needed, but document IP assignments—nobody wants duplicate addresses at 2AM.

Built to Last

CE, UL 61010-1, and RoHS certified. Siemens backs it with their standard 365-day warranty covering defects and performance failures. From my experience, these modules often outlive the machines they’re in—seen plenty hit 10+ years in climate-controlled environments.

Reviews

There are no reviews yet.