Description

LASERGAS 12944-E – In-situ TDLAS Analyzer for Fast, Selective Gas Measurement

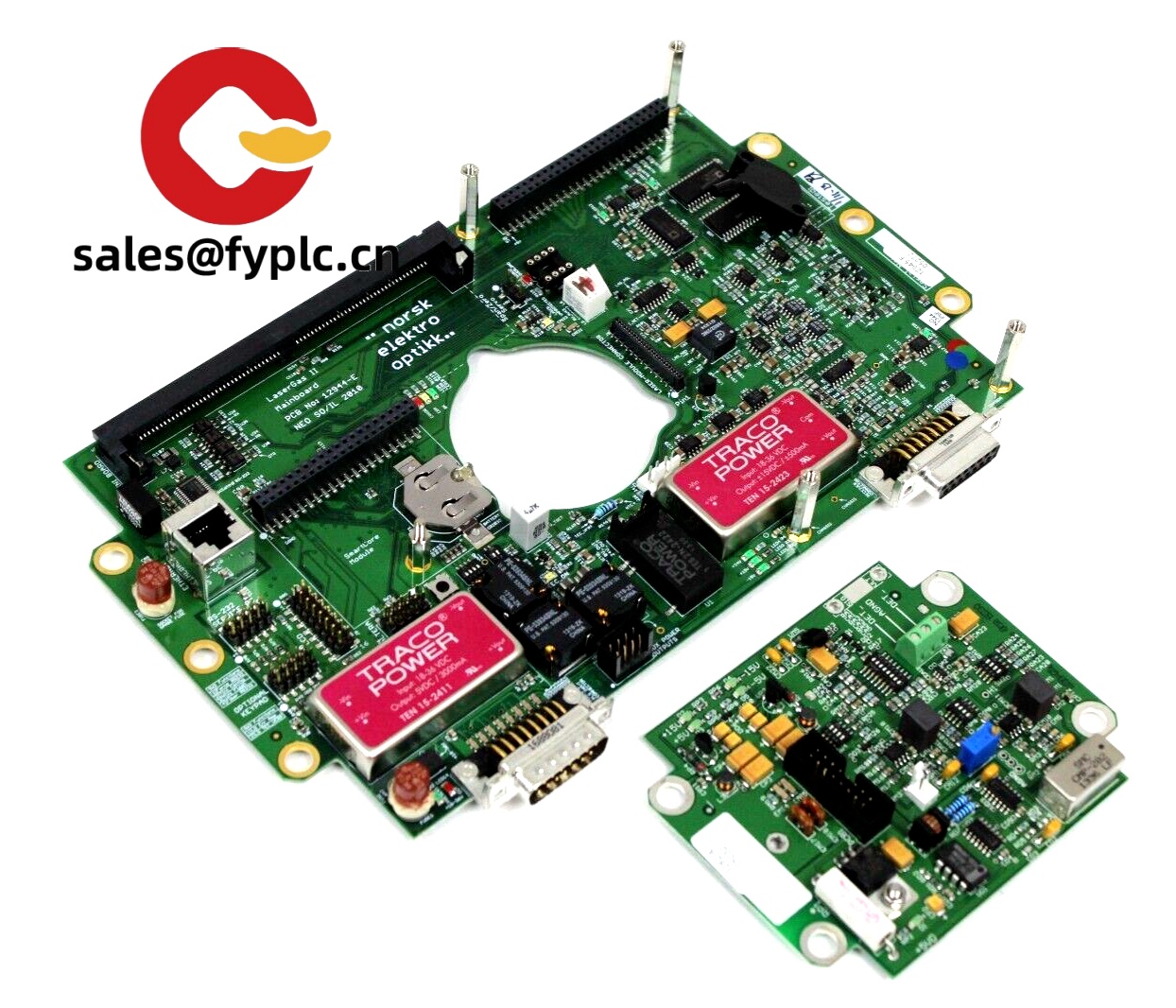

The LASERGAS 12944-E is a LaserGas-series, in-situ gas analyzer built around tunable diode laser absorption spectroscopy (TDLAS). It’s designed for real-time monitoring directly in the process duct or stack—no sampling lines, no conditioning system, and typically no moving parts. From my experience, that combination is exactly what plants want when uptime and data stability matter, whether you’re tuning combustion, protecting equipment, or keeping emissions in check.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express Options: FedEx, UPS, DHL

Key Features

- True in-situ measurement – Measures directly in the gas stream, which typically removes the need for extractive sample systems and their maintenance overhead.

- TDLAS selectivity – High spectral selectivity helps minimize cross-interference from other gases; drift tends to be low compared with NDIR or paramagnetic approaches.

- Fast response – Sub-second response is common, ideal for combustion tuning, trip interlocks, and real-time process control.

- Low maintenance design – With purged optics and no sampling lines, routine work usually focuses on keeping purge air dry and filters clean.

- Industrial connectivity – 4–20 mA analog outputs and Modbus RTU over RS‑485 integrate smoothly with DCS/PLC systems.

- Rugged enclosure – Weatherproof housing (IP65/66 typical) for outdoor or harsh areas; purge keeps lenses clear in dusty or humid processes.

- Diagnostics you can trust – Built-in self-checks and status flags help maintenance teams spot purge loss, window contamination, or alignment drift early.

- Gas flexibility – Common targets include O2, CO, CO2, HCl, NH3, CH4, H2O, and others; ranges are configured to the application.

Technical Specifications

| Brand / Model | LASERGAS 12944-E (LaserGas-series in-situ TDLAS analyzer) |

| HS Code | 9027.10 (Gas or smoke analysis apparatus) |

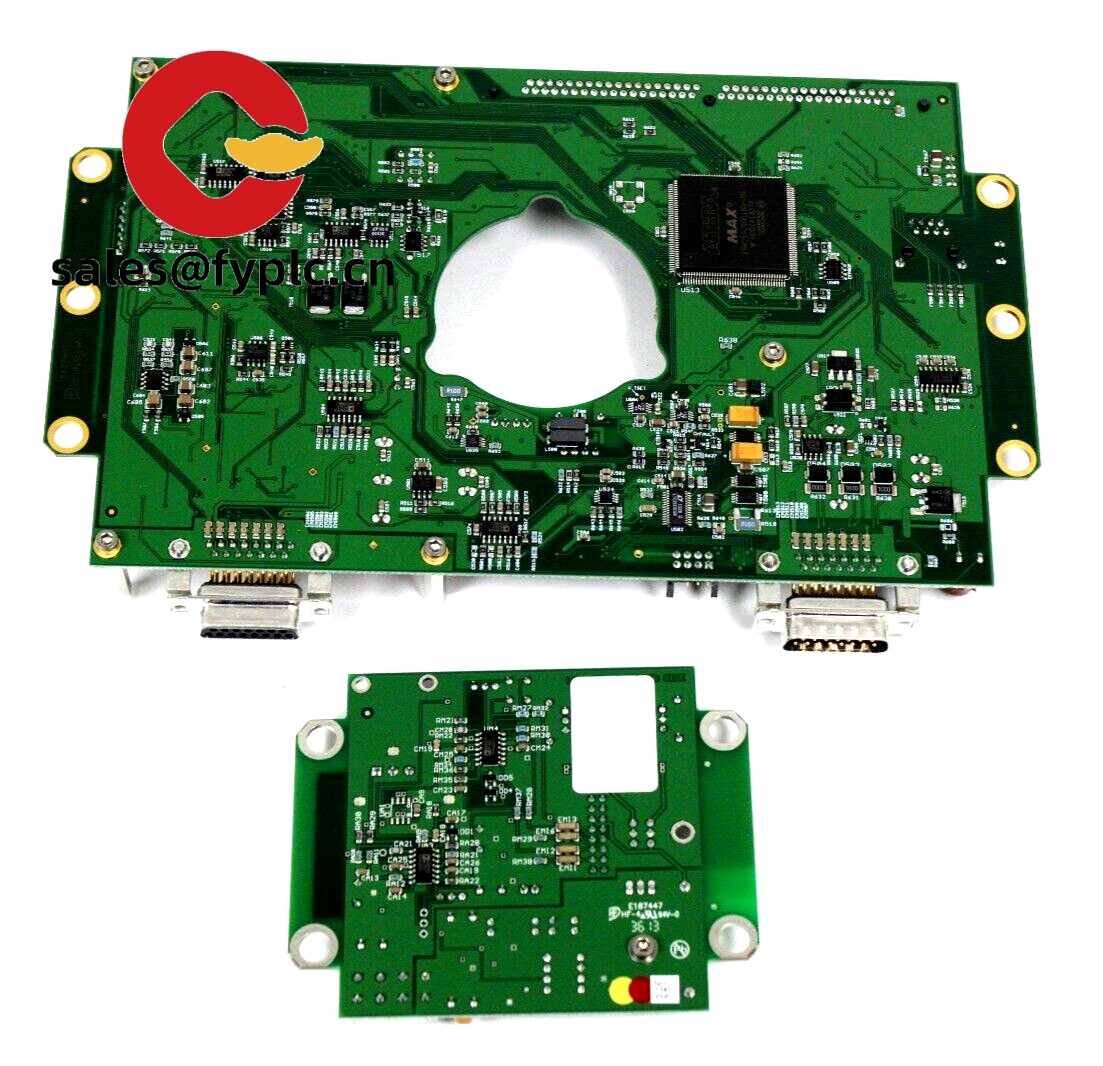

| Measurement Principle | Tunable Diode Laser Absorption Spectroscopy (TDLAS), in-situ cross-duct |

| Power Requirements | 24 VDC (typical), < 60 W depending on configuration |

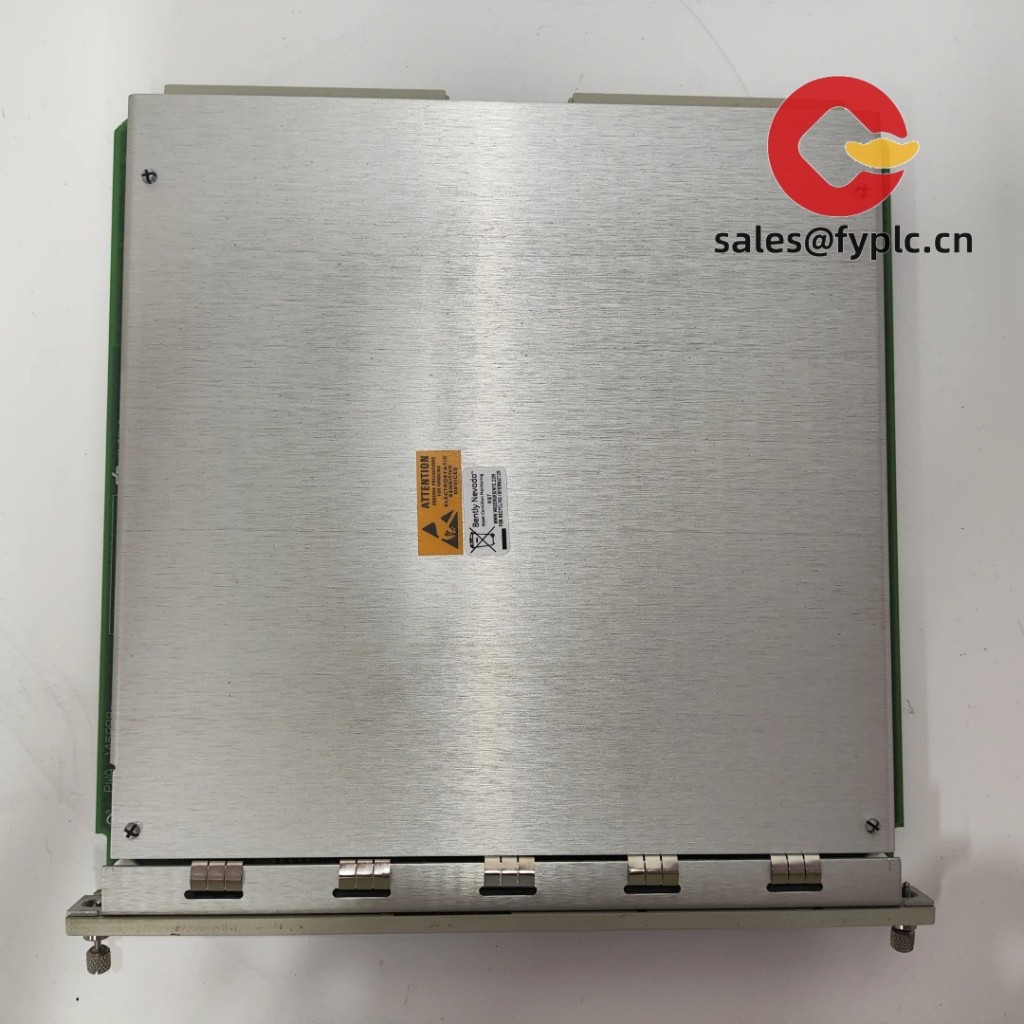

| Dimensions & Weight | Approx. 230 × 210 × 120 mm per head; ~5 kg per head (typical transmitter/receiver) |

| Operating Temperature | -20 to +55 °C for electronics; process interface capability depends on purge/cooling options |

| Signal Input/Output | 1–2 × 4–20 mA outputs (isolated, typical), status relays, service port |

| Communication Interfaces | RS‑485 (Modbus RTU, typical); gateway options available on request |

| Installation Method | Flange-mounted, cross-duct (transmitter + receiver); purge air connections for optics |

| Enclosure Protection | IP65/66 (typical) |

| Response Time | ≤ 1 s (typical) |

Application Fields

You might notice that the 12944-E slots into a lot of “hard-to-measure” spots where extractive systems struggle. Typical applications include:

- Combustion control in boilers, heaters, and furnaces (O2/CO trim for efficiency and safety).

- SCR/SNCR optimization in power and waste-to-energy plants (NH3 slip and NOx control pairing).

- Cement and metals kilns, clinker coolers, and reheat furnaces (CO, O2, H2O under high dust loads).

- Refining and petrochemical process ducts, FCC units, and flare lines (CH4, H2S, H2O as configured).

- Emissions monitoring for HCl, H2O, and CO2 where a fast in-situ check improves data confidence.

A maintenance supervisor from a cement plant put it simply: “Once the purge air was set, we mostly forgot about it—just a quick glance at diagnostics during rounds.”

Advantages & Value

- Reliability – Fewer components to fail than extractive systems; optics are protected by continuous purge.

- Compatibility – Standard 4–20 mA and Modbus RTU make DCS tie-in straightforward, even on legacy systems.

- Lower operating cost – No sample lines or chillers typically means less call-outs, fewer spares, and less downtime.

- Stable measurements – TDLAS is known for low drift and strong gas selectivity, which helps maintain compliance records.

- Supportability – Diagnostics and alignment aids speed up commissioning and simplify routine checks.

Installation & Maintenance

- Mounting – Install transmitter and receiver on opposite flanges across the duct or stack; keep path clear of obstructions and avoid severe flow swirl if possible.

- Purge air – Dry, clean instrument air is recommended to protect optics; size the purge to overcome local dust and humidity conditions.

- Wiring – 24 VDC supply with proper grounding; use shielded twisted pairs for RS‑485 and analog runs; segregate from high-voltage cabling.

- Cabinet / environment – For harsh ambient conditions, consider a sunshade or light enclosure; maintain ventilation around the electronics.

- Safety – Lockout/tagout for any duct access; confirm gas hazards and follow confined space rules; verify purge before energizing the laser.

- Routine care – Check purge filters, verify alignment status in diagnostics, and wipe windows during outages if required. Field calibration is rarely needed; a functional check against a known reference is usually enough.

- Firmware – Keep firmware at a supported release; from my experience, modest updates improve diagnostics and communication stability.

Quality & Certifications

- Conformity: CE-marking typically applicable; RoHS compliant components in many cases.

- Hazardous areas: ATEX/IECEx options available on certain variants; details depend on configuration.

- Quality system: Manufacturer commonly operates under ISO 9001-certified processes.

- Warranty: 365-day warranty as supplied with our deliveries.

If you plan to monitor a specific gas (e.g., HCl in a wet stack or NH3 slip on an SCR outlet), share the duct size, temperature, expected range, and dust load. We’ll match the LASERGAS 12944-E configuration and accessories—purge kit, alignment brackets, and any gateways—to fit your site with minimal engineering time.

Reviews

There are no reviews yet.