Description

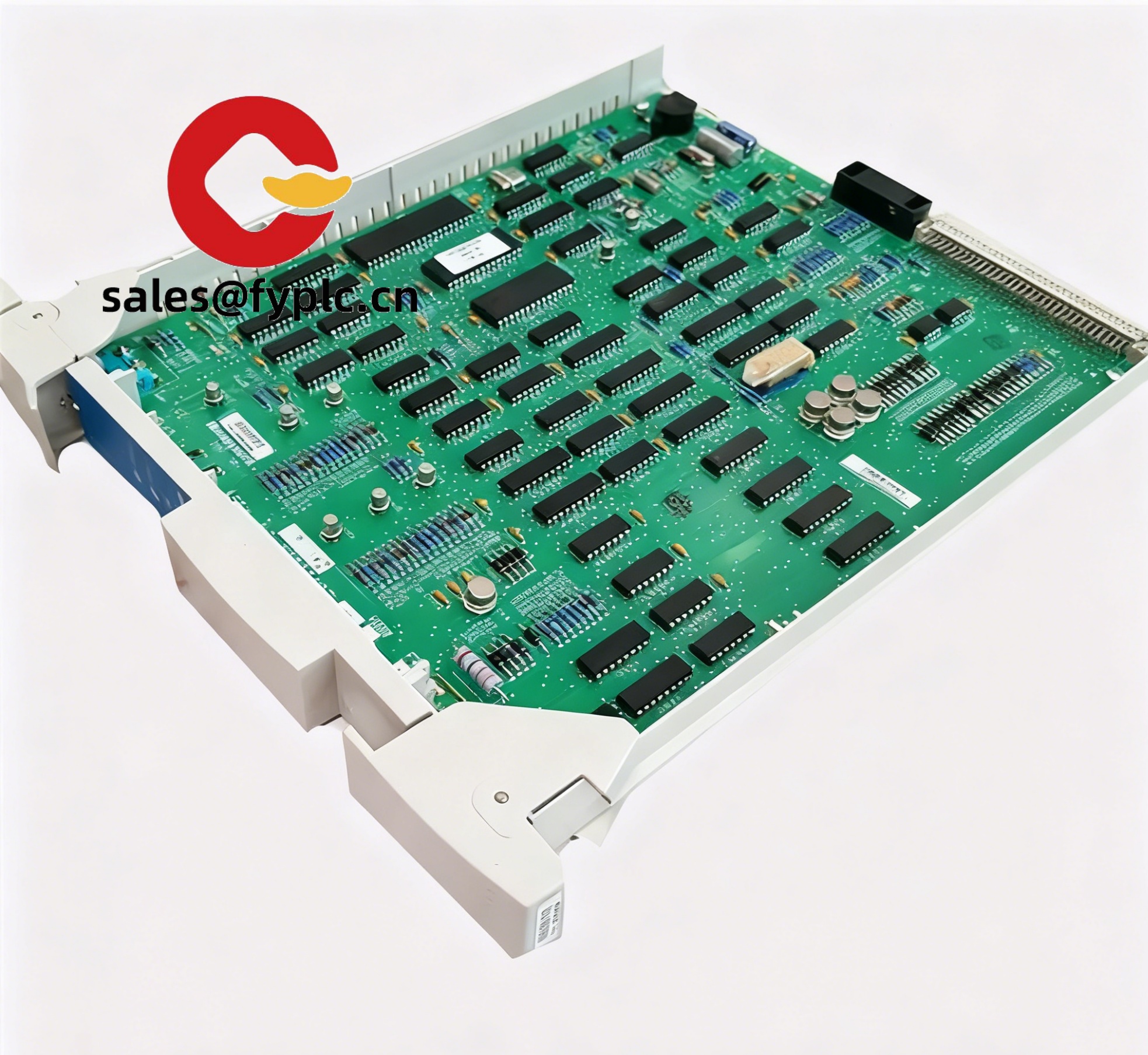

HONEYWELL MC-PDOX02 (51304487-150) – Discrete/Pulse Output Module for Honeywell DCS I/O Racks

The Honeywell MC-PDOX02, part number 51304487-150, is a discrete/pulse output module designed for Honeywell distributed control systems. From my experience, it is typically used to drive on/off devices and send pulse signals to totalizers or counters—things like solenoid valves, beacons, motor starter relays, and pulse-driven flow totalizers. Plants choose it when they need stable, rack-mounted solid-state outputs with the option to generate pulse trains without adding external hardware.

One thing I appreciate is how it drops into the existing Honeywell chassis and speaks over the system backplane—no external comm port setup or extra gateways. You might notice that maintenance teams like the straightforward status LEDs and the predictable behavior under load, which in many cases shortens troubleshooting time during shift change.

Order Placement Process and Guarantees

- Warranty: 365 days from shipment

- Lead time: Typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

- Pre‑shipment checks: Visual inspection and basic power-up/status verification are available on request

Key Features

- Discrete and pulse output capability: Suits on/off actuators and pulse-driven devices such as totalizers.

- Solid-state outputs: Typically transistor-based outputs for fast switching and long life.

- Backplane integration: Communicates via the Honeywell I/O rack backplane; no external comm ports to configure.

- Status diagnostics: Front-panel LEDs for channel state and module health aid quick troubleshooting.

- Field power at 24 VDC: In most cases supports 24 VDC field interfacing for standard industrial loads through the terminal assembly.

- Hot‑swap capability (system dependent): Many Honeywell racks allow online replacement with controller redundancy in place.

- Compatible accessories: Works with Honeywell termination/field terminal assemblies and rack backplanes commonly used in Honeywell DCS cabinets.

Technical Specifications

| Brand / Model | HONEYWELL MC-PDOX02 (Part No. 51304487-150) |

| HS Code | 8537.10 (Programmable controllers / I/O assemblies; subject to local customs interpretation) |

| Power Requirements | Powered via Honeywell system backplane; field side typically uses 24 VDC for loads through the termination assembly |

| Dimensions & Weight | Single-slot plug‑in I/O module; compact form factor for Honeywell DCS racks |

| Operating Temperature | 0 to 55 °C typical for Honeywell I/O modules (indoor control cabinet) |

| Signal I/O Types | Discrete (digital) outputs with pulse output capability; 24 VDC nominal field interface |

| Communication Interfaces | System backplane bus only; no user-facing external comm ports |

| Installation Method | Installs in a Honeywell I/O chassis with matching field terminal/termination assembly; cabinet or rack-mounted enclosure |

Application Fields

This module is commonly used across process industries where reliable digital actuation and pulsing are required:

- Oil & Gas: valve solenoids, burner management interlocks, and metering pulses to totalizers.

- Chemical & Petrochemical: dosing pumps, alarms, stack lights, and contactor control.

- Power Generation: auxiliary equipment on/off control and pulse outputs to legacy counters.

- Pharma & Food: cleanroom signaling, utility skids, and batch totalizing.

- Pulp & Paper / Mining: robust on/off outputs to interposing relays in harsh areas.

Advantages & Value

- Compatibility: Designed for Honeywell DCS racks, so it usually deploys without re-engineering the control logic.

- Reduced downtime: Fast replacement with clear status LEDs shortens fault isolation time.

- Lifecycle support: Suitable as a like-for-like spare, helping standardize your installed base.

- Cost control: Using a native Honeywell output module helps avoid external pulse generation hardware.

- Technical backing: Documentation and configuration practices are consistent with Honeywell DCS conventions.

A maintenance supervisor told me they swapped one during a scheduled window and had the channel status back online in minutes—the pulse totalizer picked up immediately after a quick configuration check. That kind of predictability matters when the line can’t stop for long.

Installation & Maintenance

- Cabinet & environment: Install in a ventilated control cabinet meeting industrial EMC practices; keep within 0–55 °C and avoid condensation.

- Wiring: Route 24 VDC field wiring to the correct termination assembly; use interposing relays for higher power loads.

- Grounding & isolation: Maintain proper panel grounding; separate signal and power wiring to reduce noise.

- Hot swap: If your chassis supports it, isolate the channel or place the controller in the recommended mode before removal—follow site MOC procedures.

- Routine checks: Periodically verify output channel operation, clean dust from the card face, and log firmware/config revisions where applicable.

- Spares: Keep at least one spare on-site for critical loops; label with firmware or revision where relevant.

Quality & Certifications

- Typically CE compliant and UL/cUL recognized for industrial control equipment.

- Manufactured under Honeywell quality systems (ISO 9001 environments are standard for major DCS product lines).

- RoHS compliance may depend on module revision; confirm per lot if required by your site policy.

- Warranty: 365 days from shipment.

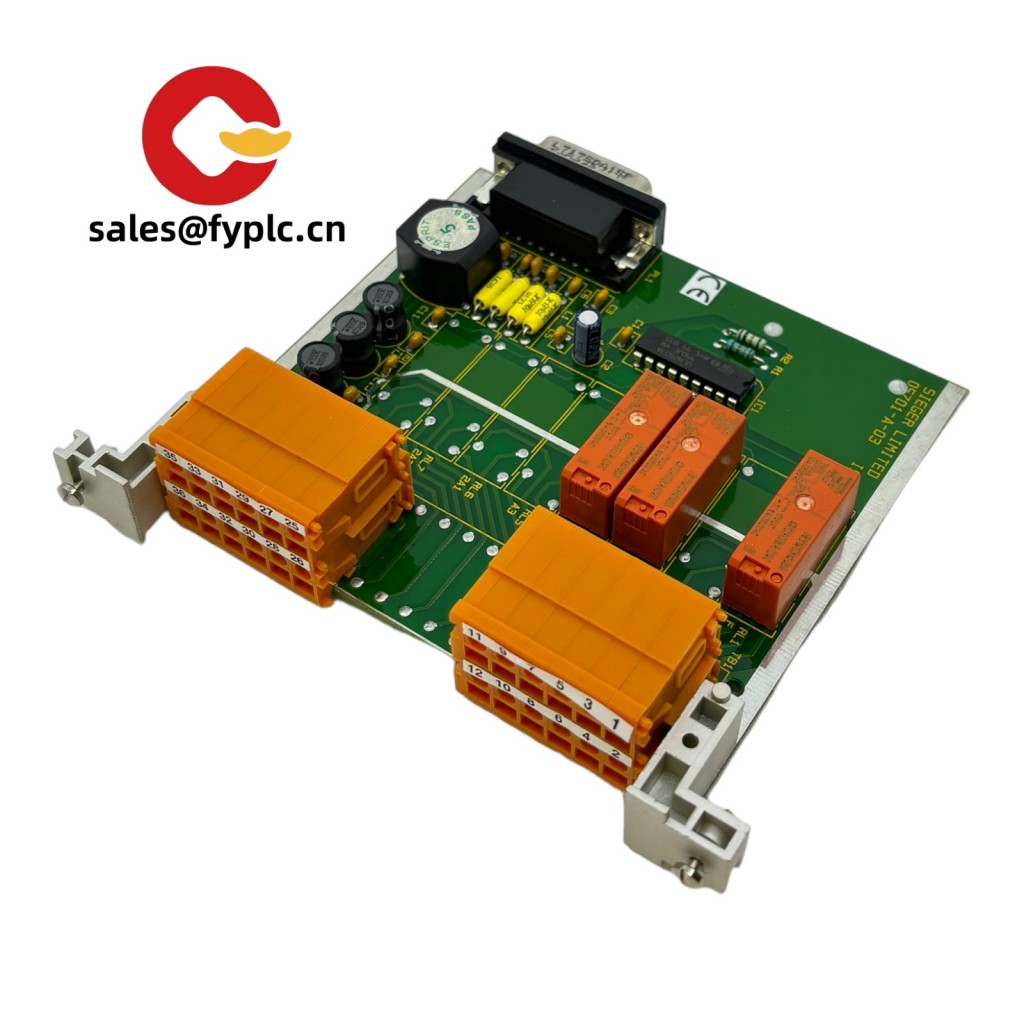

Related/Supporting Components

- Honeywell I/O chassis/backplane: Required rack position and slot addressing per Honeywell DCS guidelines.

- Field Terminal/Termination Assembly (FTA/TA): Provides the field-side connection points for 24 VDC loads and channel wiring.

- I/O ribbon or system cable: Connects the module to the termination assembly; choose the cable length and type specified for your cabinet layout.

- Interposing relays and protection: Recommended when switching higher currents or inductive loads to extend module longevity.

Reviews

There are no reviews yet.