Description

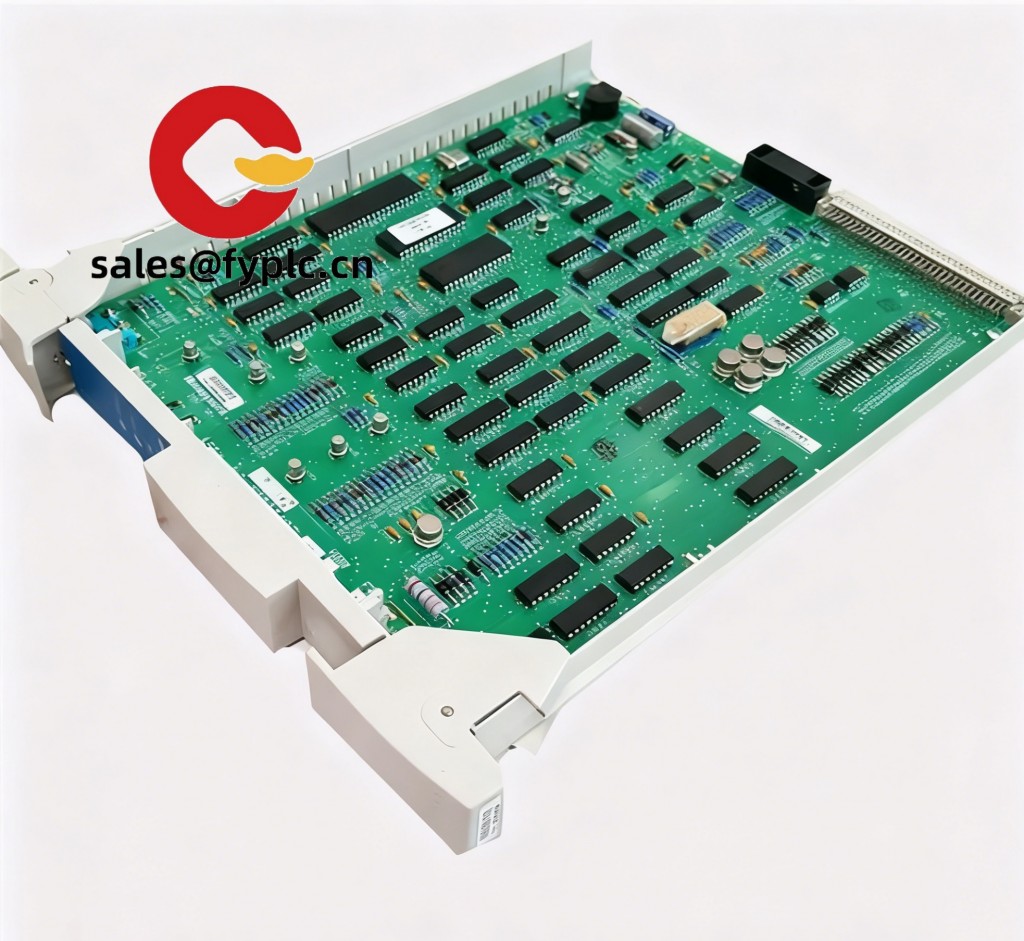

WOODWARD 8901-457 – Industrial Control Module for Engine/Turbine Protection and Speed Management

The WOODWARD 8901-457 is a genuine, factory-grade control module used in engine and turbine control systems where reliable protection, speed governing, and coordinated I/O handling really matter. From my experience, this model shows up in retrofit projects and maintenance spares for critical rotating equipment—gas/steam turbines, large reciprocating engines, and compressor trains—where downtime simply isn’t an option. One thing I appreciate is how it typically drops into existing Woodward architectures without forcing a redesign of the cabinet layout or field wiring.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

- Pre-shipment support: photos for confirmation, basic functional check, and packaging validation

Key Features

- Engine/Turbine Control Compatibility: Typically used in Woodward-based speed, protection, or sequencing applications with rotating machinery.

- Stable 24 Vdc Operation: Designed for industrial DC power systems, helping simplify cabinet power design and redundancy.

- Industrial Temperature Range: Built for control rooms and cabinets that see real plant conditions—usually suitable for -20 to +70°C environments.

- Discrete I/O and Relay Interfacing: In many cases supports dry contact inputs and relay outputs for trips, permissives, and alarms.

- Field-Proven Reliability: Woodward modules like this are known for long service life and predictable behavior, especially in safety-related loops.

- Service-Friendly Form Factor: Accessible terminals and clear labeling typically reduce service time during outages.

Technical Specifications

| Brand / Model | WOODWARD 8901-457 |

| HS Code | 9032.89 (Automatic regulating or controlling instruments and apparatus) |

| Power Requirements | 24 Vdc nominal (typically 18–32 Vdc) |

| Operating Temperature | Typically -20°C to +70°C (control cabinet environment) |

| Signal I/O Types | Commonly discrete inputs (dry contact / 24 Vdc) and relay outputs; speed pickup or analog channels may be present depending on configuration |

| Communication Interfaces | Variant-dependent; many Woodward systems support Modbus (RS‑485/RTU or Ethernet) at the system level |

| Installation Method | Cabinet-mounted electronics module; wired via terminal blocks; follow Woodward grounding and shielding practices |

Notes: Exact I/O complement and firmware options vary by 8901-457 revision and application. If you share your existing system tag or photos of the nameplate, we’ll verify compatibility before shipping.

Application Fields

- Gas and steam turbine control—speed governing, trip/overspeed logic, and permissive management

- Large engine-driven generator sets—island or grid-parallel operation with protective I/O

- Pipeline compressor trains—interlocks, shutdown logic, and sequencing

- Petrochemical and refining units—critical rotating equipment controls in hazardous duty areas (within certified cabinets)

- Marine propulsion and auxiliary machinery—where robust DC power and reliable start/stop control are essential

Advantages & Value

- Genuine and tested: We source original Woodward hardware and perform incoming QC so you don’t inherit someone else’s problem.

- Compatibility check: Share your controller tag list or panel drawing; we’ll confirm the 8901-457 suits your slot and wiring map before you commit.

- Reduced downtime: Short lead options typically beat OEM factory schedules, which in many cases means avoiding an extra outage window.

- Lifecycle support: Guidance on firmware handling, replacement planning, and recommended spares.

- Cost control: Predictable pricing and warranty reduce total risk compared with emergency sourcing during trips.

Installation & Maintenance

- Cabinet standards: Mount in a clean, dry, ventilated control cabinet. Maintain ambient within the stated range; avoid direct vibration and heat sources.

- Power and grounding: 24 Vdc supply with stable grounding; use dedicated returns and proper bonding to minimize noise.

- Wiring practices: Use shielded twisted pairs for any sensor/speed pickup lines; terminate shields per Woodward recommendations to prevent ground loops.

- ESD safety: Handle boards/modules with ESD protection; isolate power before insertion or removal.

- Routine checks: Inspect terminal tightness at outages, clean dust with dry air, and visually check for connector wear.

- Functional tests: Perform trip and permissive checks during planned shutdowns; if firmware is applicable, update only with approved release notes and backups.

- Spares strategy: Keep at least one like-for-like spare for critical trains; label firmware/config revisions to avoid mismatch on swap.

Quality & Certifications

- Manufacturer compliance typically includes CE; many Woodward modules are UL/cUL recognized for control equipment

- RoHS compliance on electronics, depending on production date and region

- 365-day warranty from shipment date

- Each unit is inspected and packed for transport shock and ESD protection

Related and Supporting Components (for smoother commissioning)

- 24 Vdc industrial power supplies (redundant A/B feeds recommended)

- Magnetic speed pickups and shielded cable sets

- Relay interposers and terminal blocks for clean segregation of field wiring

- Woodward actuators and drivers for fuel/steam valves, as required by your prime mover

You might notice that specifications can vary slightly by revision and application kit. If you can share the existing system model or photos of the 8901-457 nameplate, we’ll validate form, fit, and function before we lock in the shipment date.

Reviews

There are no reviews yet.