Description

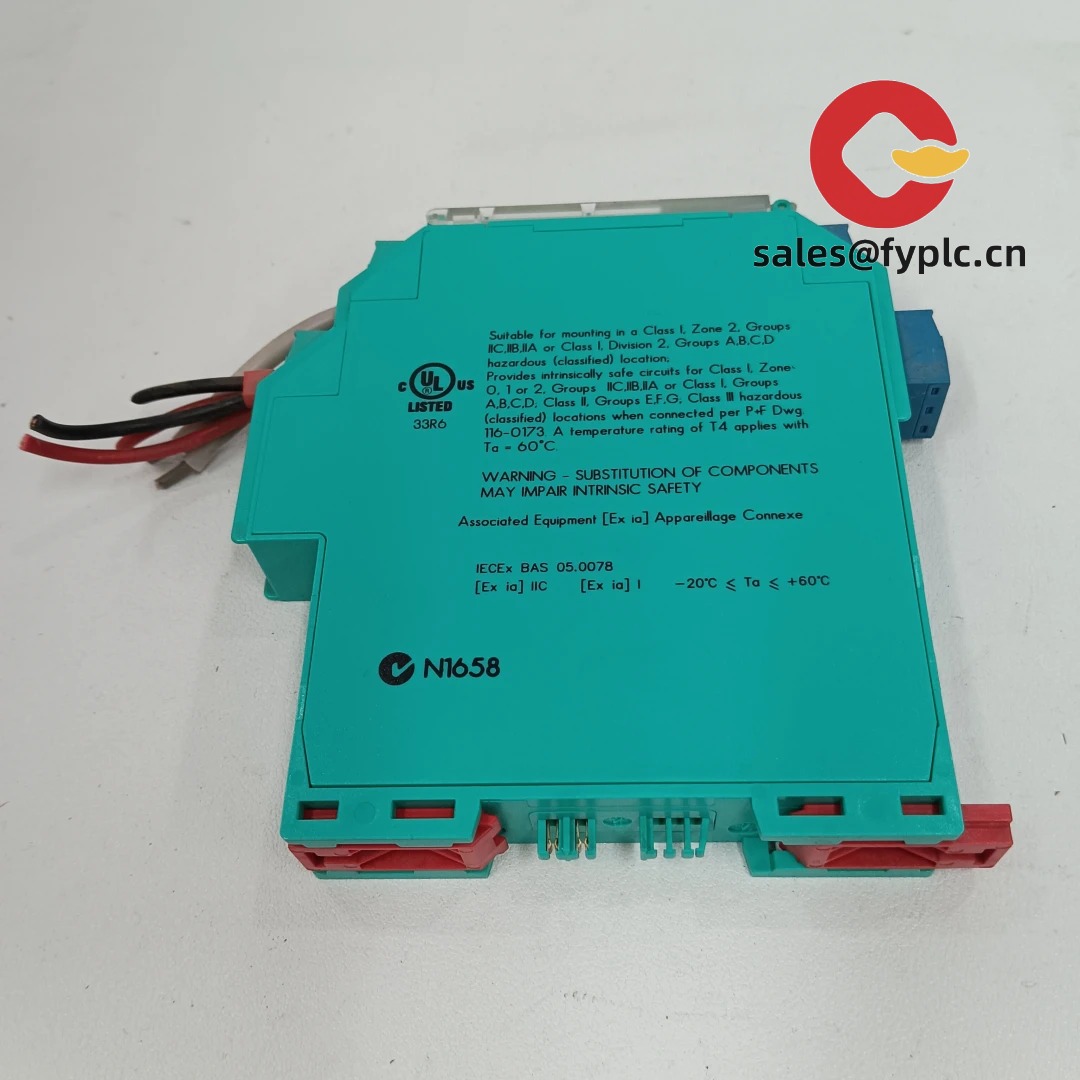

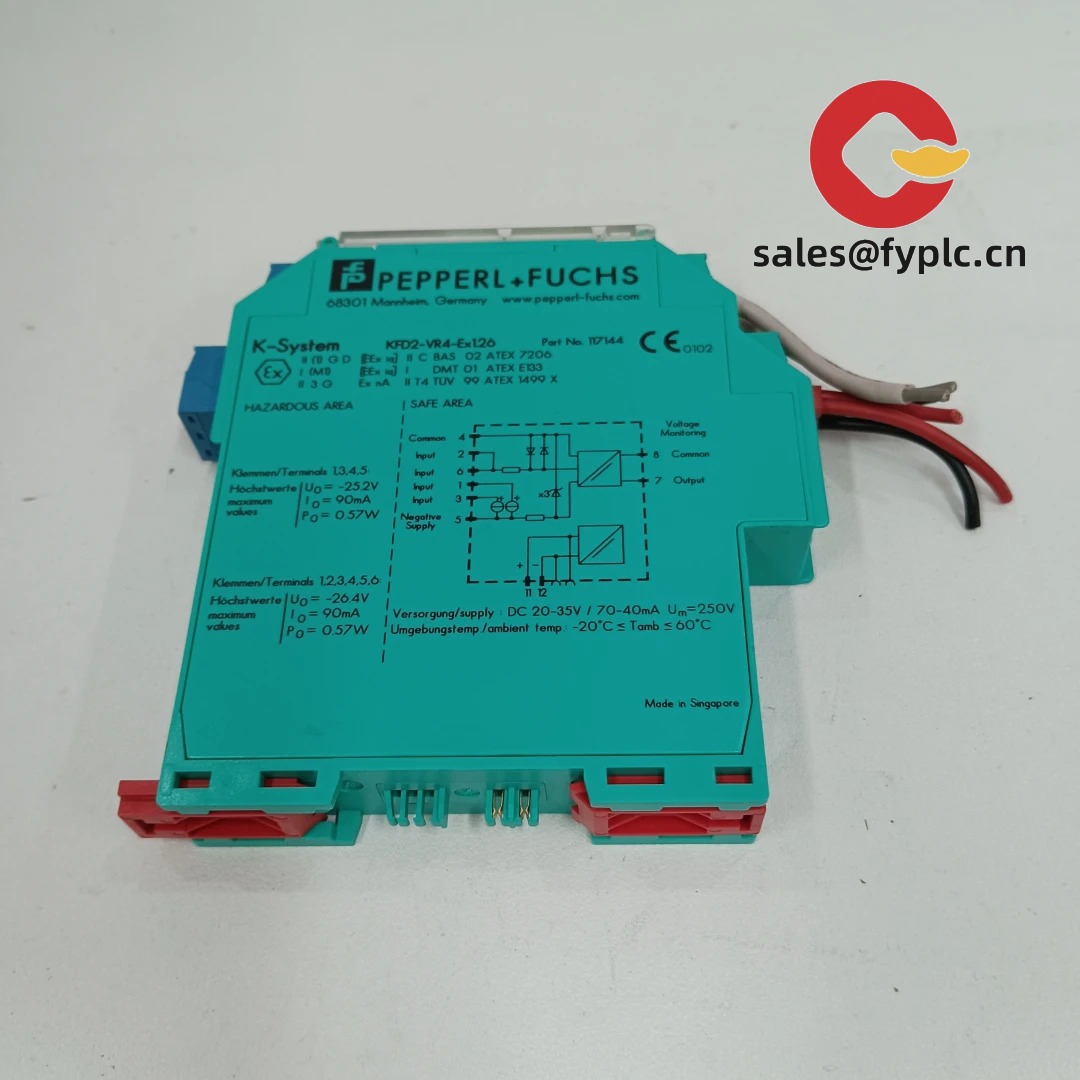

Pepperl+Fuchs KFD2-VR4-Ex1.26 – Intrinsically Safe Multi‑Channel Repeater Power Supply / Switch Amplifier for NAMUR Sensors

The Pepperl+Fuchs KFD2‑VR4‑Ex1.26 is part of the proven K‑System family, designed to bring NAMUR proximity sensors and simple contacts from hazardous areas into the safe area with galvanic isolation and dependable line fault detection. One thing I appreciate is how it consolidates multiple channels into a compact DIN‑rail form factor, which typically cuts cabinet space and wiring time. You might notice it’s sometimes listed as “KFD2‑VR4‑Ex126” in quotations—the dot is just omitted; it’s the same model.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Intrinsic safety for field circuits (Ex) – Interfaces NAMUR sensors from Zone 0/1 to the safe area with galvanic isolation.

- Multi‑channel design – VR4 indicates a four‑channel architecture, typically reducing module count and panel width versus single‑channel barriers.

- NAMUR/dry contact compatibility – Accepts EN 60947‑5‑6 NAMUR inputs or simple mechanical contacts in many cases.

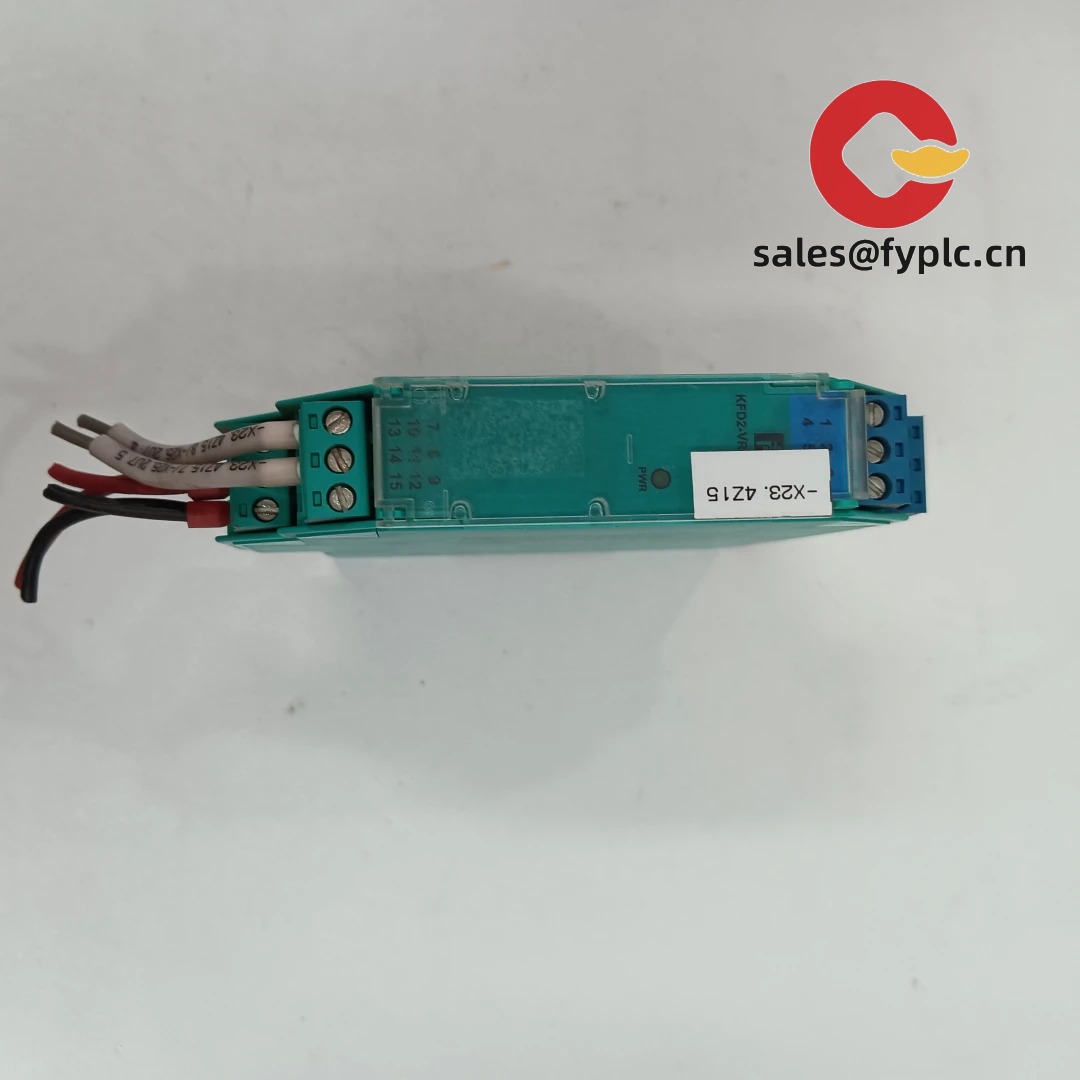

- Clear diagnostics – Front LEDs per channel for sensor state and line fault; makes commissioning faster from my experience.

- Line fault detection – Open/short‑circuit monitoring helps spot field wiring issues early.

- Power Rail ready – Works with K‑System Power Rail for clean power distribution and optional collective fault signaling.

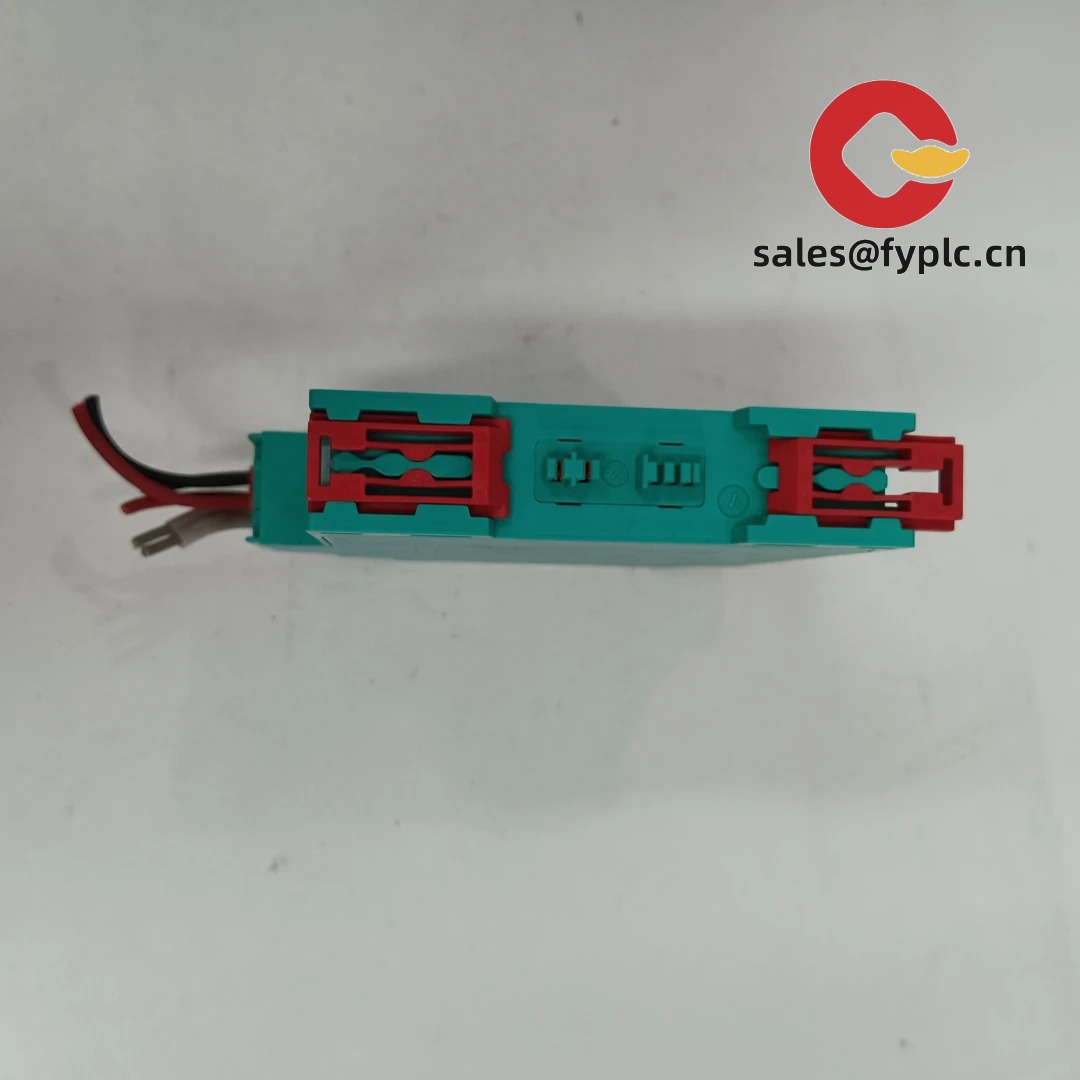

- Rugged industrial housing – DIN‑rail mount with robust isolation; suitable for continuous operation in typical plant environments.

Technical Specifications

| Brand / Model | Pepperl+Fuchs KFD2‑VR4‑Ex1.26 |

| HS Code | 8543.70 (Electrical apparatus with individual functions) |

| Power Requirements | 24 V DC nominal (typically 20…30 V DC), via terminals or Power Rail |

| Signal Input / Output Types | Inputs: NAMUR proximity sensors or dry contacts; Outputs: isolated control signals to the safe area (relay/contact variants are common for this series) |

| Communication Interfaces | No fieldbus; optional collective fault via K‑System Power Rail when used with a suitable feed module |

| Dimensions & Weight | Approx. 119 × 40 × 115 mm (H×W×D); approx. 200 g (typical for 4‑channel K‑System modules) |

| Operating Temperature | -20…+60 °C (typical for K‑System modules; verify against your site standard) |

| Installation Method | DIN rail (TS35) in safe area; hazardous‑area field wiring to intrinsically safe inputs; Power Rail compatible |

Application Fields

This module fits where you have multiple IS sensors and limited panel depth: chemical process units, tank farms, blending skids, compressor stations, and packaging lines in Zone 1 corridors. Typical use cases include:

- Bringing NAMUR proximity switches from hazardous areas to DCS/PLC digital inputs

- Monitoring valve position feedback and limit switches in Ex zones

- Pump run/stop feedback and interlocks where intrinsic safety is required

- Level/alarm contacts on storage tanks and loading racks

A maintenance supervisor told us the VR4 layout “cleaned up four sensor loops in one shot,” and they especially liked the quick LFD diagnosis during a turnaround—seems to be a small thing that saves hours when you’re under time pressure.

Advantages & Value

- Reliability – Proven K‑System electronics with stable isolation and predictable behavior in 24/7 operation.

- Compatibility – Works with standard NAMUR sensors and common PLC/DCS input cards; minimal rework needed.

- Panel Efficiency – Multi‑channel design typically reduces the number of modules and terminal blocks.

- Lifecycle Cost – Fewer modules, faster troubleshooting, and Power Rail distribution usually lower total install and maintenance costs.

- Support – From my experience, P+F documentation and K‑System accessories make expansions and replacements straightforward.

Installation & Maintenance

- Panel/Cabinet – Mount on TS35 DIN rail in a clean, ventilated enclosure. Leave a small air gap on each side if panel temperatures run high.

- Wiring – Keep IS field wiring separated from non‑IS conductors; follow NAMUR polarity; use appropriate blue marking for IS circuits.

- Power Rail (optional) – For larger racks, use the Pepperl+Fuchs Power Rail with a suitable feed module for neat power distribution and collective fault.

- Safety – Verify entity parameters and hazardous area classifications before energizing; maintain proper grounding of the rail and panel door bond.

- Routine checks – Visual LED check during rounds; periodically test LFD by simulating open/short on a spare sensor loop.

- Firmware – No firmware updates are typically required for this device; keep records of loop drawings and settings for audits.

Supporting Components (Typical)

- Power Rail PR‑03 – Backplane for K‑System modules to distribute 24 V DC and fault signaling.

- KFD2‑EB2 Power Feed Module – Feeds and monitors the Power Rail, enabling collective fault output to the DCS/PLC.

- Shielded sensor cables – NAMUR‑rated, with proper blue identification for intrinsically safe circuits.

Quality & Certifications

- Certifications – Typically CE, ATEX, IECEx, and regional approvals such as FM/CSA for Class I Div. 1 interfaces; RoHS compliant.

- Manufacturer’s warranty – Backed by our 365‑day warranty for this supply.

If you’re standardizing on K‑System, this model is a safe pick for multi‑loop NAMUR signals where space and diagnostics matter. Share your loop count and cabinet constraints, and we’ll match quantities and accessories so installation goes smoothly.

Reviews

There are no reviews yet.