Description

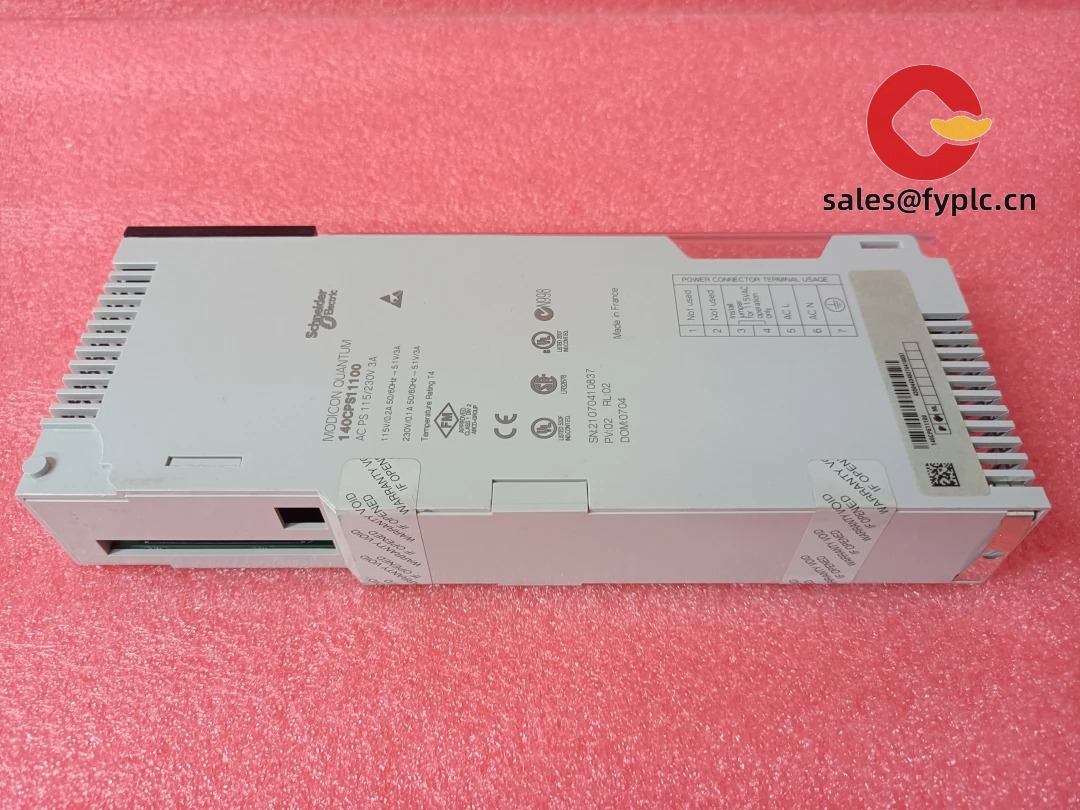

Schneider Electric 140CPS11100 – Modicon Quantum AC Power Supply Module for Reliable Rack Backplane Power

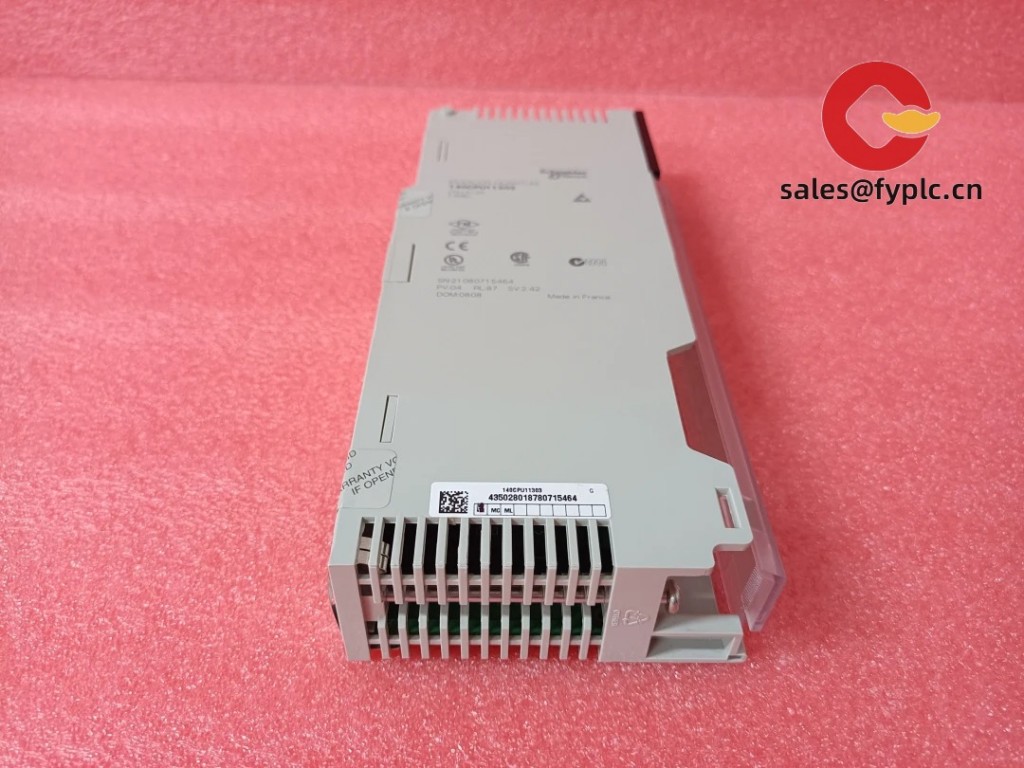

The Schneider Electric 140CPS11100 is the AC power supply module used in Modicon Quantum racks. In simple terms, it converts plant mains into the stable backplane power your CPU and I/O need. From my experience, maintenance teams keep this exact part on hand because a clean, like-for-like swap gets a Quantum rack back online fast—no cabinet changes, no rewiring, just move the terminal block and verify LEDs. You might notice the familiar Quantum mechanics and status indicators on the front, which makes checks during a shutdown window very straightforward.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and basic electrical checks; ESD‑safe, shock‑resistant packing

Key Features

- AC mains input – Designed for industrial 50/60 Hz mains (commonly 115/230 VAC) to feed the Quantum rack.

- Backplane power for CPU and I/O – Provides the regulated 5 V DC backplane supply Quantum hardware expects.

- Status at a glance – Front LEDs help you confirm input presence and backplane health quickly.

- Protection built in – Overload and thermal protections typically safeguard the rack from abnormal conditions.

- Straight drop‑in – Same single‑slot mechanics and terminal layout keep swaps predictable during short outages.

Technical Specifications

| Brand / Model | Schneider Electric 140CPS11100 |

| System Family | Modicon Quantum – AC Power Supply Module |

| HS Code (reference) | 8504.40 – Static converters / power supplies (final classification may vary by country) |

| Power Requirements (input) | AC mains input, typically 115/230 VAC, 50/60 Hz (check nameplate for site setting) |

| Backplane Output | Regulated 5 V DC for Quantum CPU/I&O; size rack load per Schneider power budget rules |

| Communication Interfaces | None (power module; status via front indicators) |

| Installation Method | Single‑slot Quantum plug‑in; mounts in the rack’s designated power supply position; front terminal block for mains wiring |

| Operating Temperature | Typically 0…+60 °C (cabinet‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | Quantum single‑slot format; ~0.3–0.6 kg |

Application Fields

Wherever a Quantum rack is running 24/7, the 140CPS11100 is the standard way to keep the backplane stable:

- Water & wastewater – distributed Quantum panels around plants and pump stations.

- Power & utilities – boiler/BOP cabinets and balance‑of‑plant I/O racks.

- Chemicals, refining, and pipelines – long‑run operation where clean switchover matters.

- Food & beverage – validated cabinets where a like‑for‑like PSU swap eases change control.

One thing I appreciate is how predictable a replacement is. A plant electrician told me last month, “We moved the mains leads to the new 140CPS11100, checked the LEDs, and the rack came up steady in minutes.”

Advantages & Value

- Reliability – Stable backplane power for continuous duty; fewer nuisance resets when wiring is tidy.

- Compatibility – Native Quantum mechanics; no cabinet rework or engineering changes in most cases.

- Cost control – Extends the productive life of installed Quantum systems without migrating platforms.

- Support – We can help confirm input voltage setting, power budget, and terminal mapping before your window.

- Lead‑time clarity – Practical deliveries aligned with planned outages.

Installation & Maintenance

- Mains wiring: Use appropriately rated conductors, fusing, and earth; verify the input voltage range/setting on the module.

- Power budget: Sum CPU and I/O backplane draw; keep margin per Schneider guidelines to avoid brownouts.

- EMC practice: Route AC away from low‑level analog; use a solid panel ground; tighten terminals to spec.

- Commissioning: Check front LEDs for input/backplane OK; monitor CPU start behavior and any rack diagnostics.

- ESD & handling: Strap to ground; seat firmly for full backplane engagement; de‑energize before removal.

- Routine care: Periodic dust cleaning, terminal re‑torque, and a quick log of input voltage and rack load during PMs.

Quality & Certifications

- Manufactured under Schneider Electric quality systems (ISO 9001 aligned).

- CE marking for EMC/Low Voltage; many Quantum modules are UL/cUL Recognized.

- RoHS compliance by series generation; confirmable by part/serial if required.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.