Description

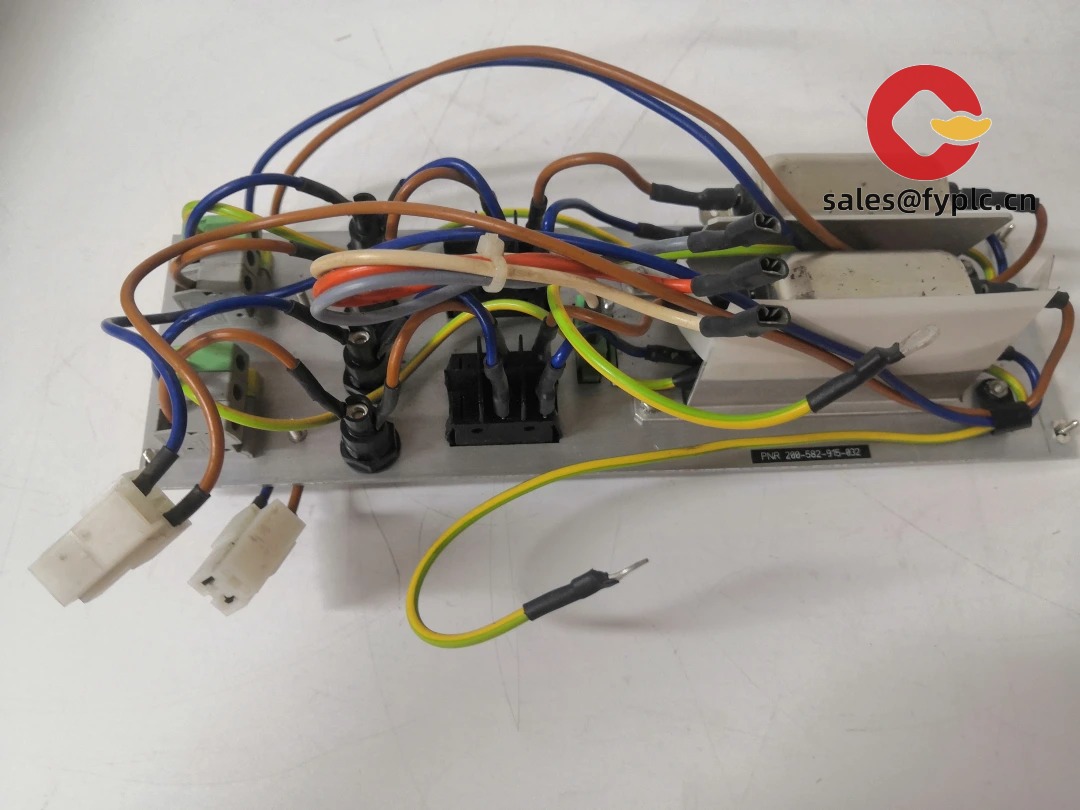

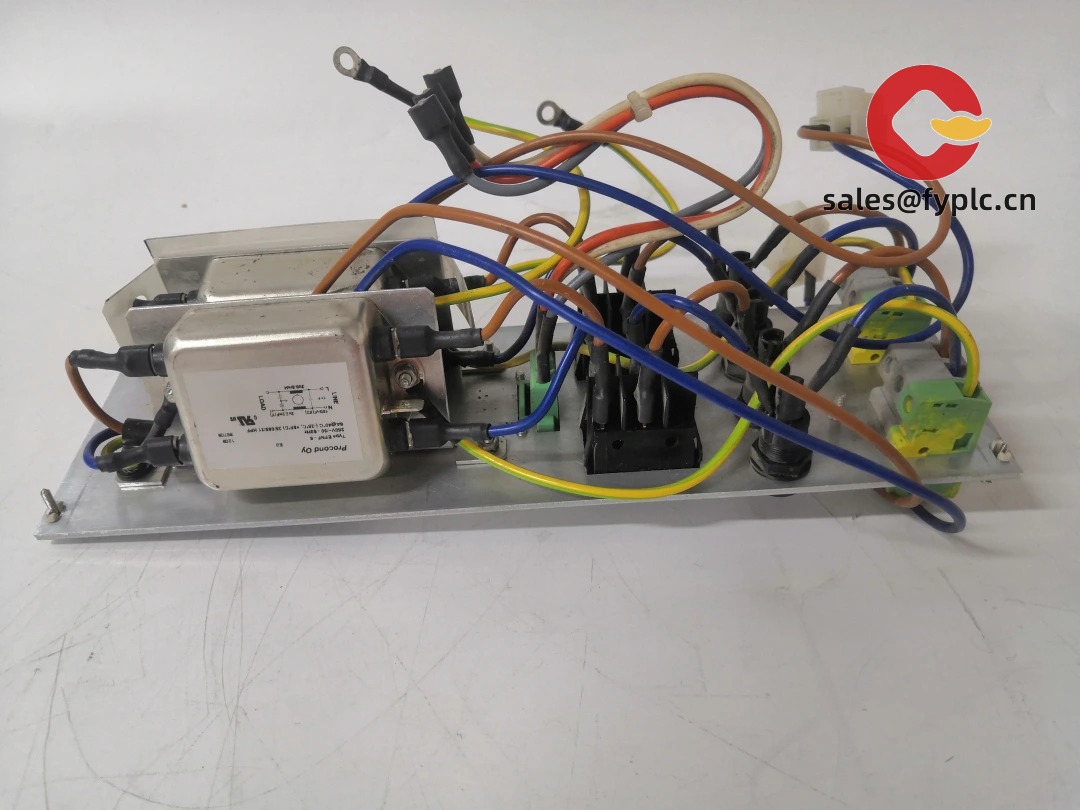

VIBRO 200-582-915-032_VM600 – VM600 System Accessory for Reliable Wiring/Replacement in Machinery Monitoring Racks

The VIBRO 200-582-915-032_VM600 is an OEM accessory for VM600 machinery protection/condition monitoring systems. From my experience, parts in this code range are typically used as direct, like‑for‑like replacements in existing VM600 racks—helping you maintain wiring integrity and restore monitoring without reworking cabinet layouts. You might notice the rugged industrial build and clear labeling; swaps during short outage windows tend to be predictable when the part code matches your installed base.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and fit check where applicable; ESD‑safe, shock‑resistant packing

Key Features

- VM600‑compatible build – OEM part code alignment ensures connector/pinout compatibility in existing racks.

- Drop‑in replacement – In most cases installs without cabinet redesign or rewiring, keeping change control simple.

- Industrial robustness – Housing and terminals suited for 24/7 duty near rotating equipment.

- Service‑friendly identification – Clear labeling and orientation cues make swap‑outs predictable during short outages.

- Clean signal practice – Designed to support shield continuity and tidy routing for low‑noise vibration/proximity signals.

Technical Specifications

| Brand / Model | VIBRO 200-582-915-032_VM600 |

| Product Category | VM600 system accessory / replacement assembly (rack wiring/installation component) |

| HS Code (reference) | 9031.90 – Parts of measuring or checking instruments (final classification may vary by country) |

| Power Requirements | Passive component; no external power (uses host/rack connections) |

| Signal I/O Types | Supports VM600 channel routing (e.g., proximity/acceleration sensors, buffered/relay paths as per module type) |

| Communication Interfaces | None (mechanical/electrical interface component for the VM600 system) |

| Operating Temperature | Typically 0…+55 °C (cabinet‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | Compact accessory form factor; typical weight ~0.2–0.5 kg (variant‑dependent) |

| Installation Method | Install per VM600 drawing; secure connectors; maintain shield continuity and strain relief |

Application Fields

You’ll typically see this part used to keep VM600 monitoring reliable on:

- Turbomachinery: gas/steam turbines and centrifugal compressors.

- Critical rotating assets: pumps, blowers, motors, gearboxes.

- Oil & gas, power generation, petrochem, paper—brownfield sites standardized on VM600.

A reliability engineer told me last month, “We matched the 200‑582‑915‑032 code, landed the shields, and the monitor came back clean on the first scan.” That’s been my experience too when the variant matches the original build.

Advantages & Value

- Reliability – OEM‑spec fit and finish that stands up to 24/7 operation.

- Compatibility – Like‑for‑like replacement keeps wiring, drawings, and alarm settings intact.

- Cost control – Extends the life of your installed VM600 without platform changes.

- Support – We can help confirm interchange codes, wiring notes, and shield termination before your shutdown.

- Lead‑time clarity – Practical deliveries that fit outage planning.

Installation & Maintenance

- Cabinet standards: Clean, ventilated enclosure; keep ambient typically 0…55 °C; non‑condensing.

- Wiring: Separate low‑level vibration/proximity leads from power conductors; maintain 360° shield bonds and strain relief.

- ESD handling: Use a grounded strap; handle by edges; store in ESD‑safe packaging.

- Commissioning: Verify pinout/labeling, torque terminals, and confirm channel readings in the monitor after install.

- Routine care: Periodic dust cleaning, connector re‑torque, and a quick trend check to confirm signal quality.

Quality & Certifications

- Produced to industrial quality standards typically aligned with ISO 9001.

- CE/UL applicability depends on the exact variant and year; we can verify by part/serial.

- RoHS status may vary by build; confirmation available on request.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.