Description

GE 531X305NTBAJG1 – NTBA Terminal/Interface Board for Legacy GE Drive & Excitation Cabinets

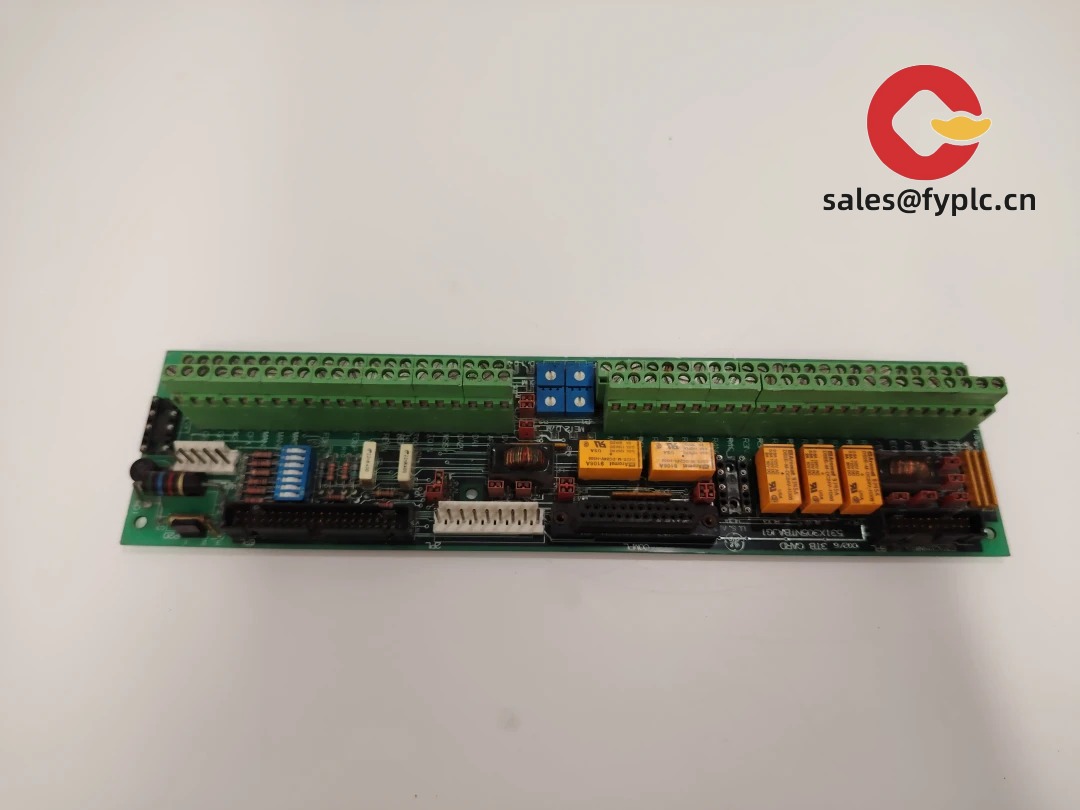

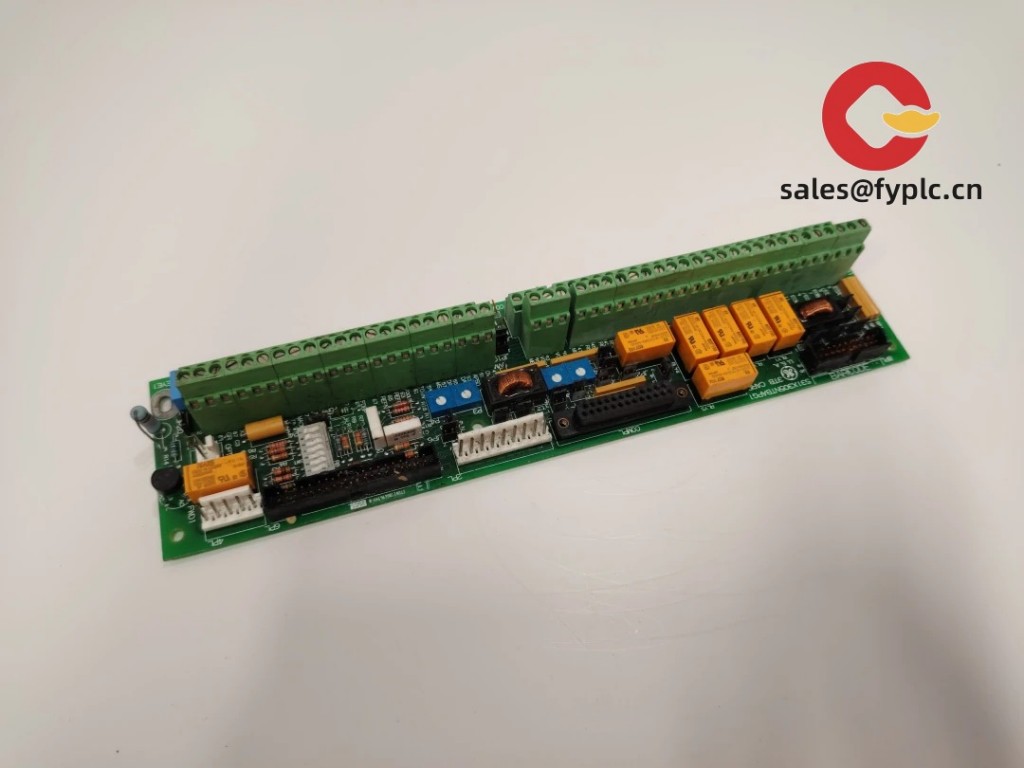

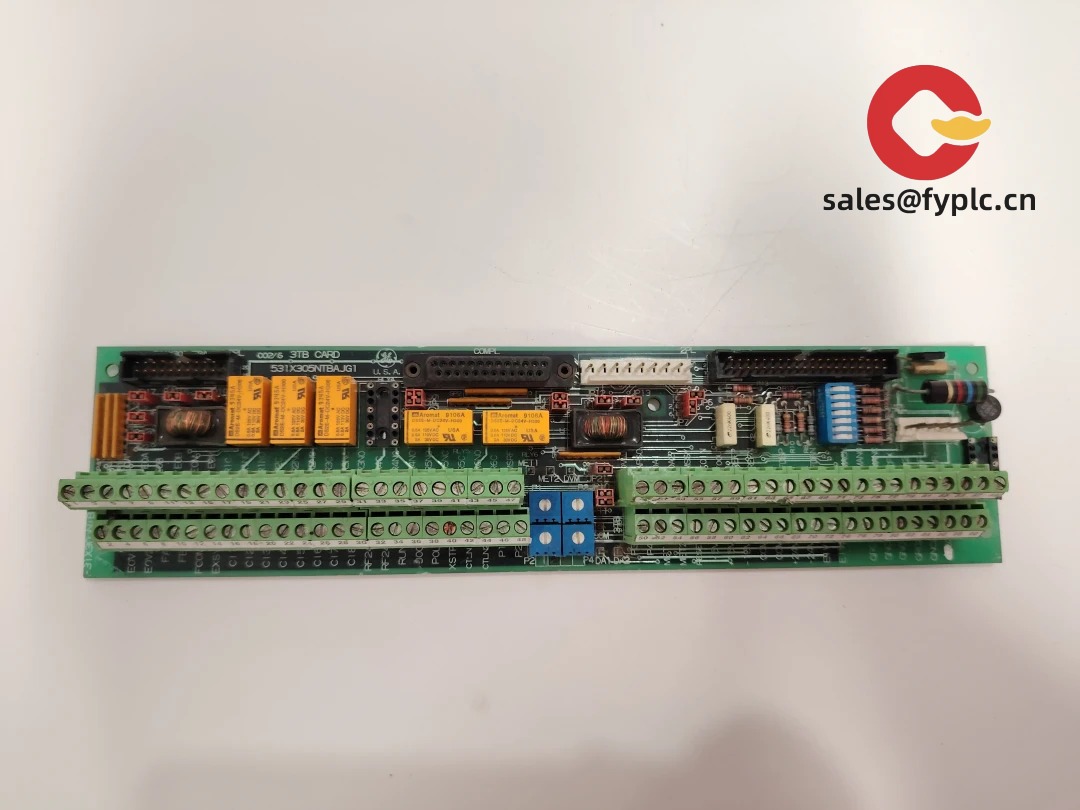

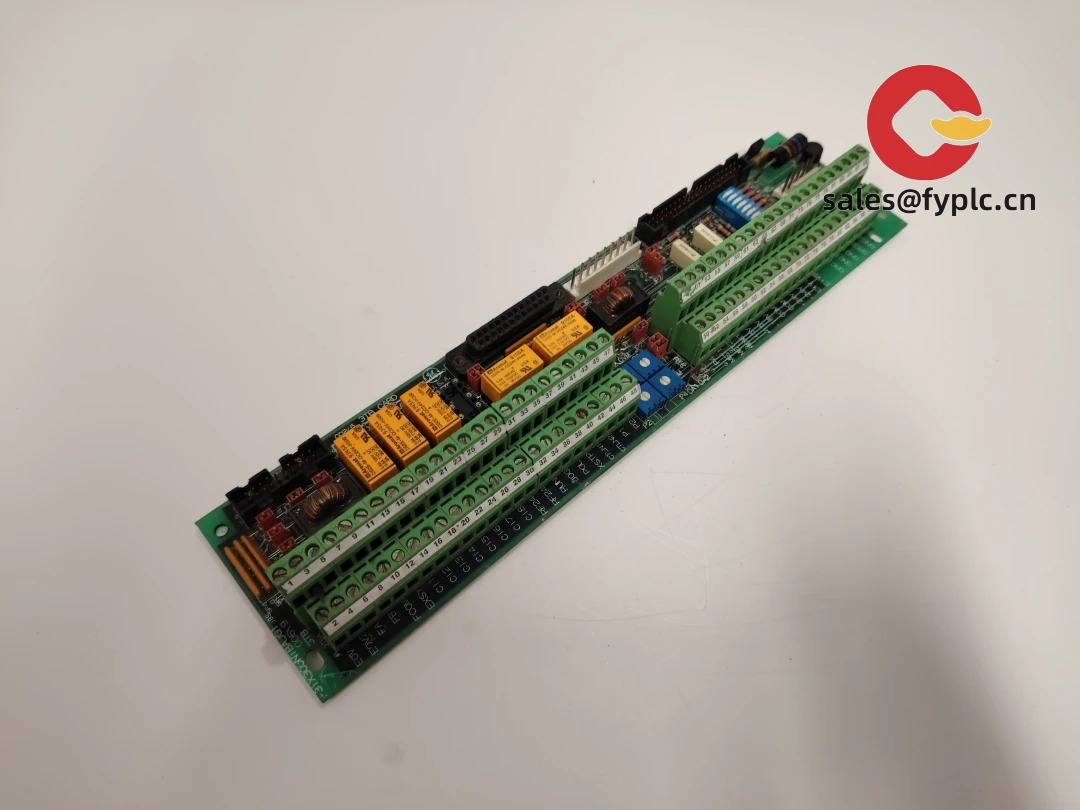

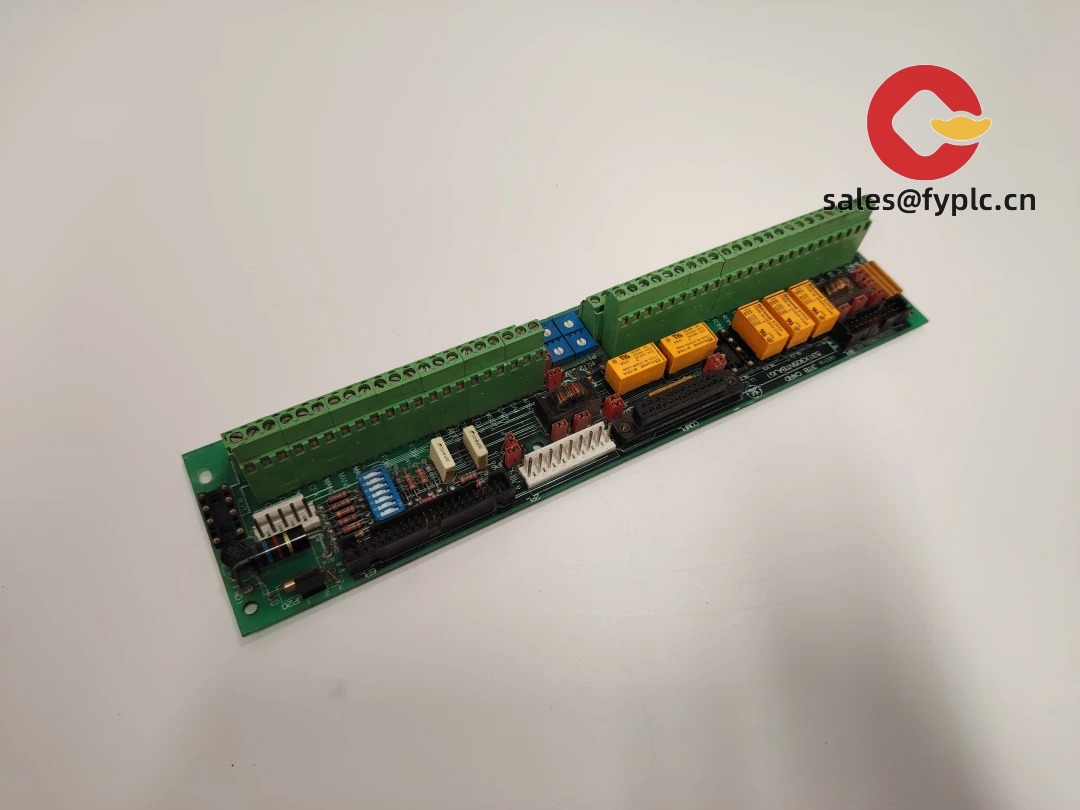

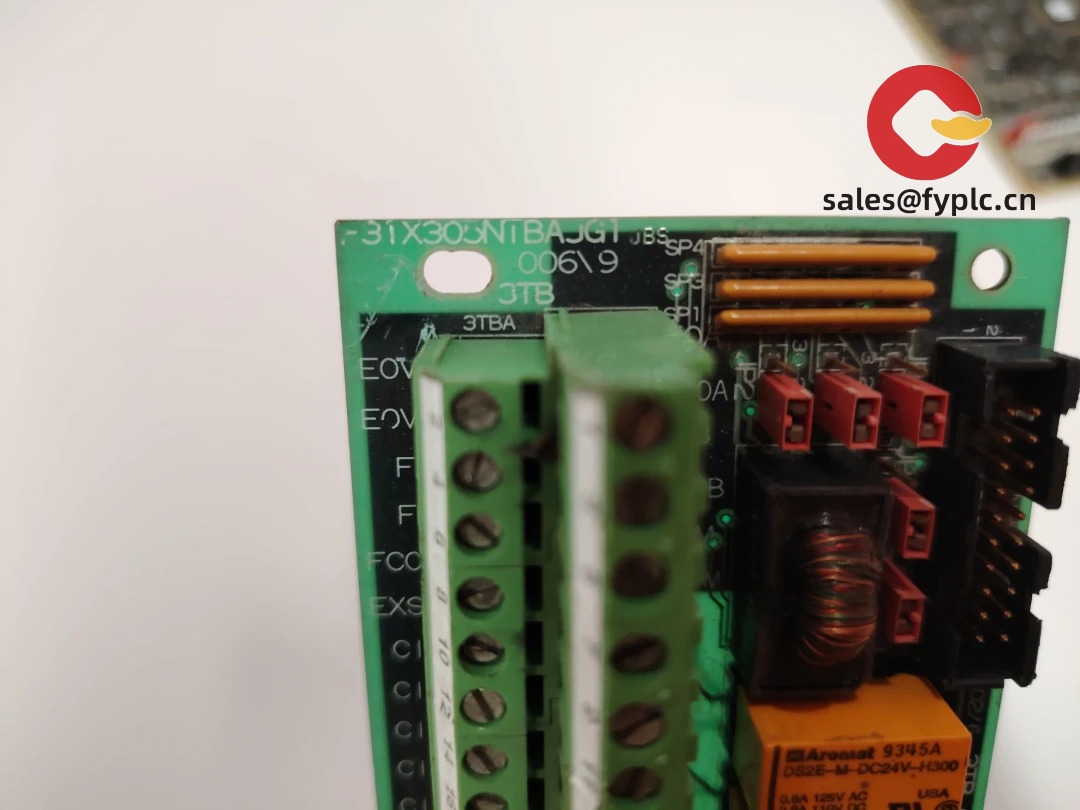

The GE 531X305NTBAJG1 is an NTBA terminal/interface board from the 531X series, used in legacy GE drive and excitation systems to land field wiring and distribute control signals. From my experience, maintenance teams keep this exact G1 variant as a like‑for‑like spare—seat the board, move the terminal leads, hook up the ribbon/backplane connectors, and the cabinet is typically ready for enable checks without rewiring. You might notice the dense terminal layout and clear labeling in the photos; that’s what makes swap‑outs during short windows predictable.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and connector integrity check; ESD‑safe, shock‑resistant packing

Key Features

- Field I/O landing board – Consolidates cabinet wiring on labeled terminals for fast, tidy installs.

- Ribbon/backplane interfacing – Connects to companion control cards in the 531X family to route analog and discrete signals.

- Service‑friendly layout – Clear terminal identification and test points typically shorten commissioning and fault‑finding.

- Like‑for‑like replacement – G1 variant intended to drop into existing GE drive/exciter racks with minimal engineering effort.

- Built for 24/7 duty – Robust PCB design that holds up well in electrically noisy drive enclosures.

Technical Specifications

| Brand / Model | GE 531X305NTBAJG1 |

| Series / Role | 531X legacy drive/excitation hardware – NTBA terminal/interface board |

| HS Code (reference) | 8538.90 – Parts for electrical control equipment (final classification may vary by country) |

| Power Requirements | Powered via cabinet supply/backplane; no separate external supply on the field side in most cases |

| Signal Input/Output Types | Terminal landings for analog references/feedbacks and discrete signals; ribbon/backplane links to control cards |

| Communication Interfaces | Internal cabinet interconnects (no external fieldbus on this board) |

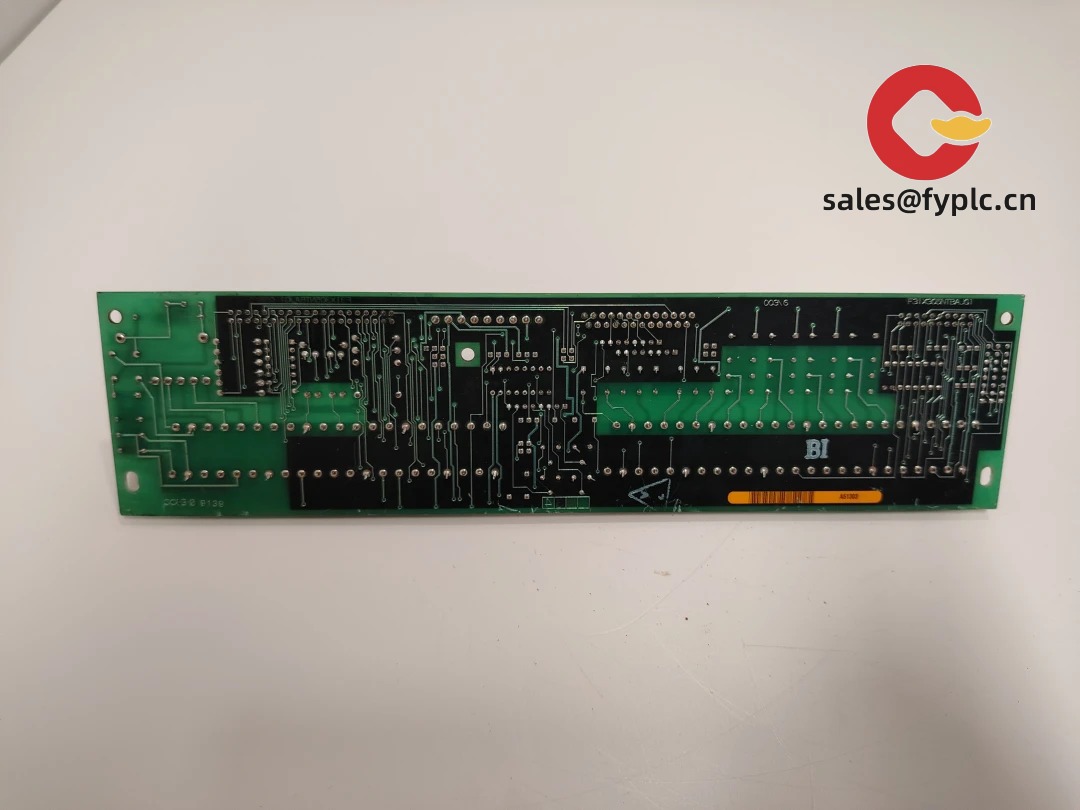

| Dimensions & Weight (approx.) | PCB format typical for 531X: ~300 × 200 mm; ~0.35–0.6 kg |

| Operating Temperature | Typically 0…+55 °C (cabinet‑installed; non‑condensing) |

| Installation Method | Mount on standoffs in GE drive/excitation cabinet; connect ribbon/backplane; land field terminals per drawing |

Application Fields

You’ll typically find the 531X305NTBAJG1 in legacy GE cabinets where stable wiring and fast service matter:

- Metals rolling and processing – organized field I/O landings for drive interlocks and analog loops.

- Pulp & paper – reliable wiring interface for long‑running sections.

- Power generation/exciters – structured terminal board for excitation controls.

- Mining/material handling – rugged terminalization in high‑noise electrical rooms.

A maintenance lead told me, “We swapped the NTBA board, moved the terminal leads over one‑for‑one, and the cabinet enabled cleanly.” That’s been my experience too when the variant code matches.

Advantages & Value

- Reliability – Robust PCB and terminal hardware that stands up to 24/7 service.

- Compatibility – G1 variant aligns with installed 531X systems, keeping drawings and wiring intact.

- Cost control – Extends legacy asset life; avoids re‑engineering cabinet wiring looms.

- Support – We can help confirm interchange and provide terminal maps before your window.

- Lead‑time clarity – Practical deliveries and tested units to fit outage planning.

Installation & Maintenance

- ESD & handling: Use a grounded wrist strap; handle by edges; store in ESD‑safe packaging.

- Mounting: Align standoffs and fully seat ribbon/backplane connectors; tighten hardware evenly.

- Wiring: Move terminalized field leads one‑for‑one; keep analog/signal wiring away from motor power; maintain shield continuity.

- Commissioning: Verify terminal labeling vs. cabinet drawing; perform a dry‑run I/O check; confirm enable/interlock behavior.

- Routine care: Periodic dust cleaning, terminal re‑torque, and a quick continuity check on critical loops.

Quality & Certifications

- Manufactured to GE industrial quality standards, typically aligned with ISO 9001.

- Component‑level spare; CE/UL compliance is usually addressed at the system level.

- RoHS status can vary by build generation; verification by part/serial is available.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.