Description

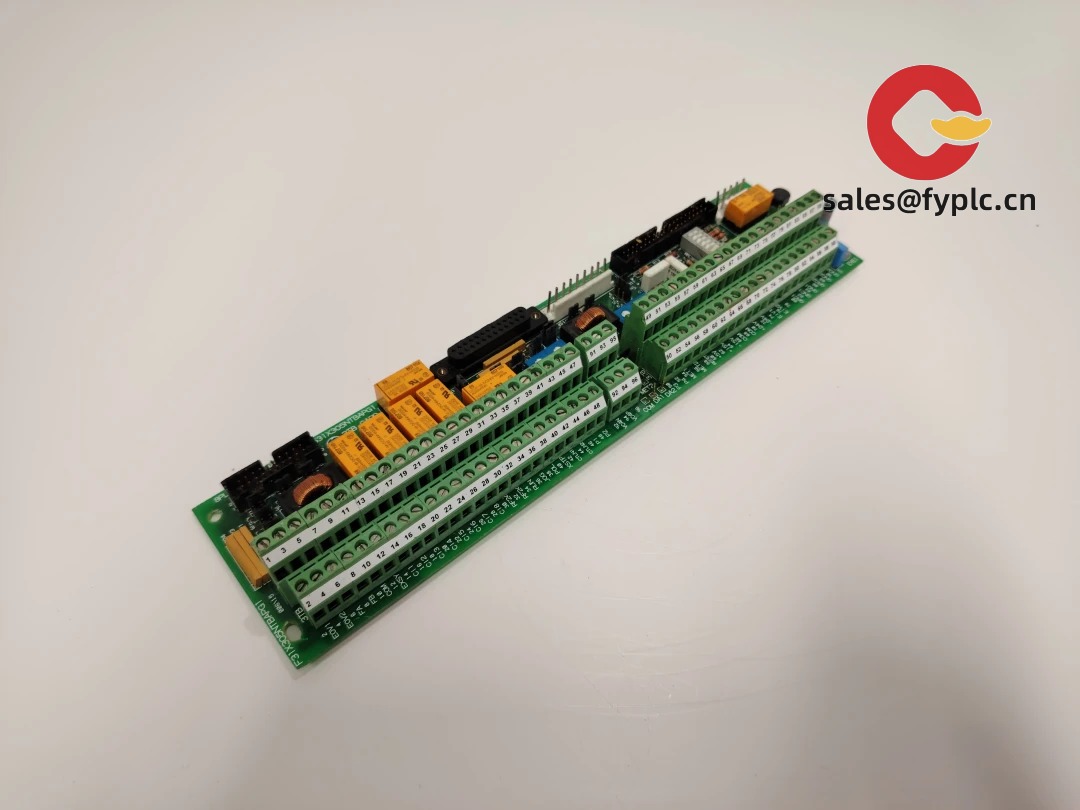

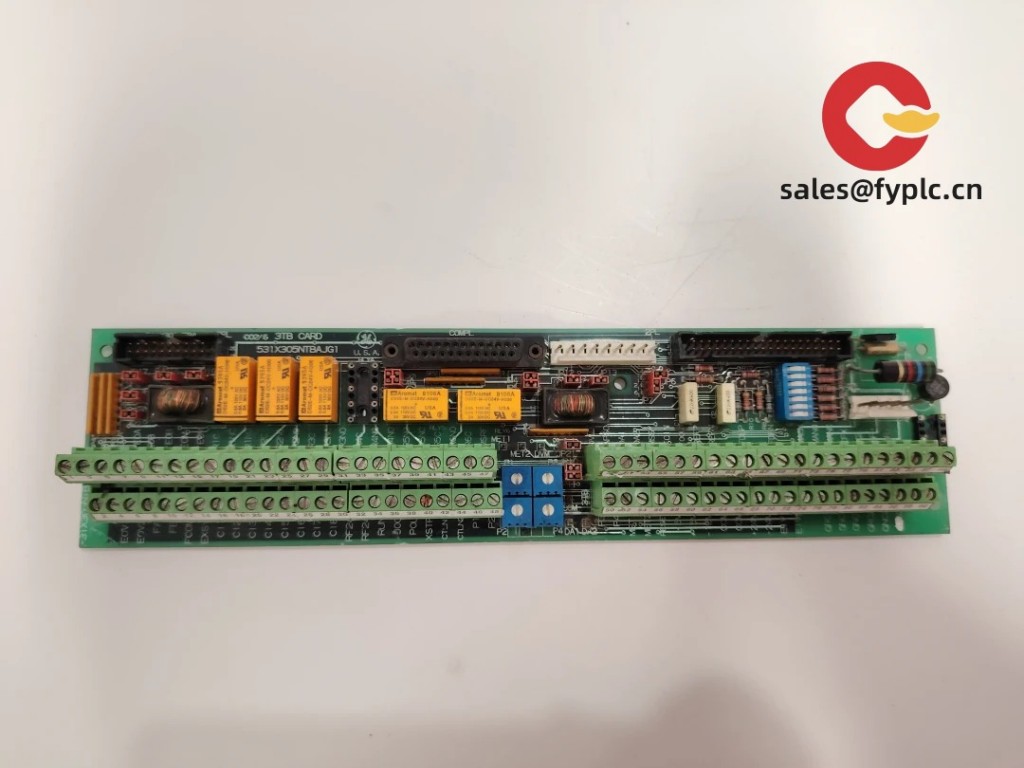

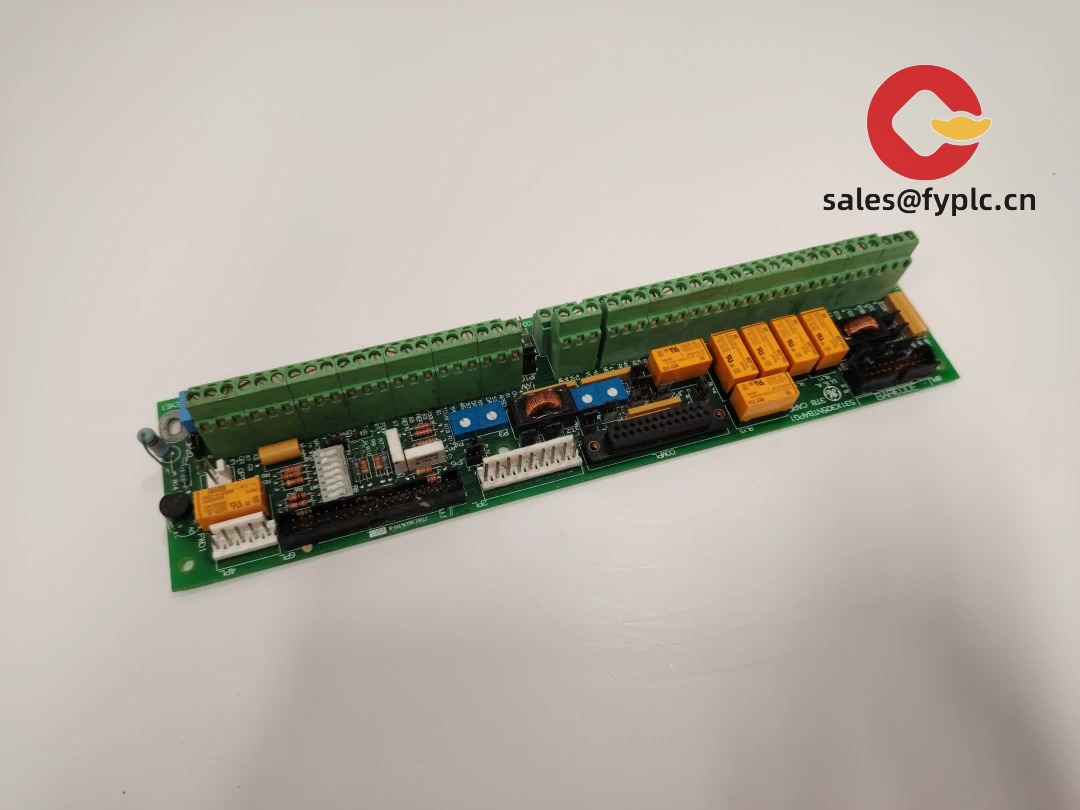

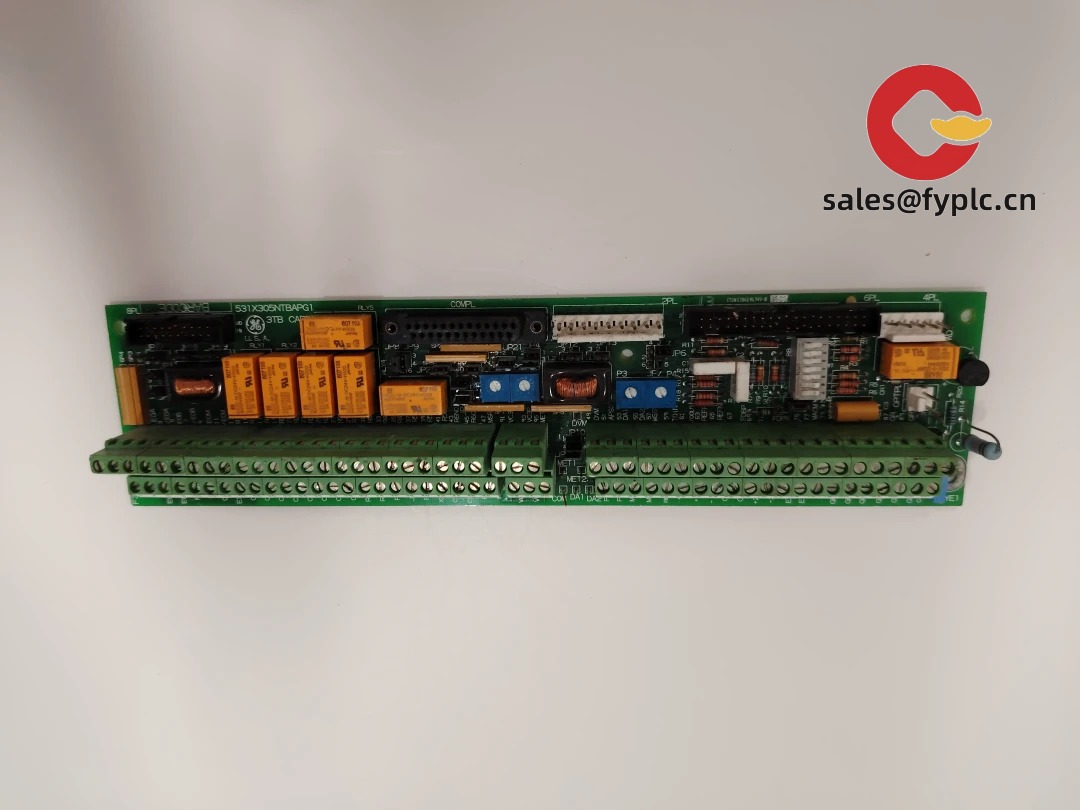

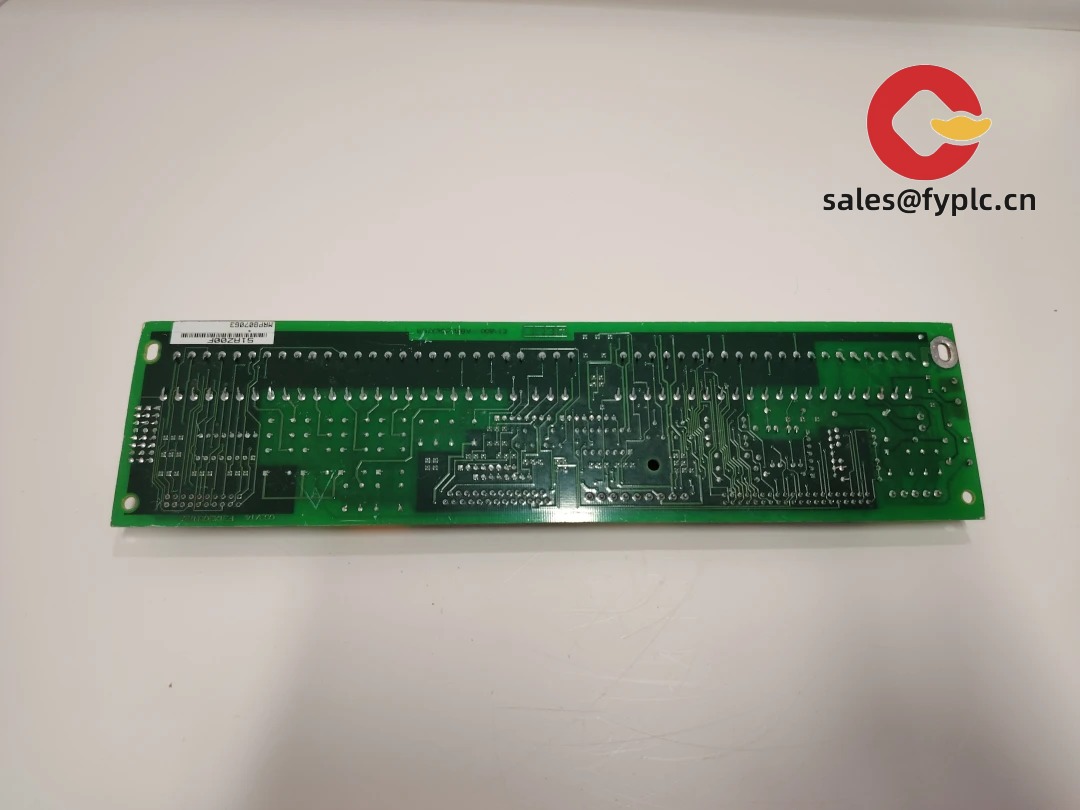

GE 531X305NTBAPG1 – NTBA Terminal/Interface Board for Legacy GE Drive & Excitation Cabinets

The GE 531X305NTBAPG1 is an NTBA terminal/interface board from the 531X series, used to land field wiring and route analog/discrete signals inside legacy GE drive and excitation systems. From my experience, plants keep this exact PG1 variant as a like‑for‑like spare—seat the board, move the terminalized leads one‑for‑one, plug the ribbon/backplane connectors, and you’re typically ready for enable checks without rewiring or drawing changes. You might notice the dense terminal layout and clear labeling; that’s what makes swaps during short maintenance windows predictable.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week if in stock; no more than one month at the latest

- Payment terms: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification, connector integrity check; ESD‑safe, shock‑resistant packing

Key Features

- Field I/O landing – Labeled terminal strips organize analog references, feedbacks, and discrete interlocks for tidy service.

- Ribbon/backplane interfacing – Mates with companion 531X control cards to route signals reliably through the cabinet.

- Like‑for‑like replacement – PG1 variant is intended to match installed bases, minimizing wiring changes and documentation churn.

- Service‑friendly layout – Clear labeling and accessible test points typically speed commissioning and fault‑finding.

- Built for 24/7 duty – Rugged PCB and terminals that hold up in electrically noisy drive enclosures.

Technical Specifications

| Brand / Model | GE 531X305NTBAPG1 |

| Series / Role | 531X legacy hardware – NTBA terminal/interface board for GE drive/excitation cabinets |

| HS Code (reference) | 8538.90 – Parts for electrical control equipment (final classification may vary by country) |

| Power Requirements | Powered via cabinet supply/backplane; no separate external field supply on the board in most cases |

| Signal I/O Types | Terminal landings for analog/discrete signals; ribbon/backplane links to companion control cards |

| Communication Interfaces | Internal cabinet interconnects only (no external fieldbus on this board) |

| Dimensions & Weight (approx.) | PCB ~300 × 200 mm; ~0.35–0.6 kg typical for 531X boards |

| Operating Temperature | Typically 0…+55 °C (cabinet‑installed; non‑condensing) |

| Installation Method | Mount on standoffs; connect ribbon/backplane; move terminalized field leads per cabinet drawing and torque spec |

Application Fields

You’ll typically find the 531X305NTBAPG1 in legacy GE cabinets where tidy terminalization and quick service matter:

- Metals rolling and processing – organized interlocks and analog loops for drive sections.

- Pulp & paper – clean field wiring interfaces in long‑running lines.

- Power generation/exciters – structured terminal board for excitation system I/O.

- Mining/material handling – robust terminalization in high‑noise electrical rooms.

A maintenance supervisor told me, “We swapped the NTBA PG1, moved the wires over one‑for‑one, and the drive enabled on the first try.” That matches what I usually see when the variant code lines up.

Advantages & Value

- Reliability – Sturdy PCB and terminals suited for 24/7 cabinets.

- Compatibility – PG1 variant aligns with installed 531X systems, keeping wiring and drawings intact.

- Cost control – Extends legacy asset life and avoids re‑engineering looms or control cards.

- Support – Help available to confirm interchange, terminal maps, and pre‑startup checks.

- Lead‑time clarity – Practical deliveries and tested units that fit planned outages.

Installation & Maintenance

- ESD & handling: Grounded wrist strap; handle by edges; keep the board in ESD‑safe packaging until install.

- Mounting: Align standoffs and fully seat ribbon/backplane connectors; tighten hardware evenly.

- Wiring: Move terminalized leads one‑for‑one; separate low‑level analog from motor power; maintain shield continuity.

- Commissioning: Verify labeling vs. drawings, torque terminals, perform a dry‑run I/O check, then enable and observe interlocks.

- Routine care: Periodic dust cleaning, terminal re‑torque, and continuity checks on critical loops during PMs.

Quality & Certifications

- Manufactured to GE industrial quality standards, typically aligned with ISO 9001.

- Component‑level spare; compliance (CE/UL) is generally handled at the system level.

- RoHS status can vary by build; we can confirm by part/serial on request.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.