Description

HONEYWELL 0574-A-0121 / 0574-A-0131 – OEM Wiring/Adapter Harness Set for Honeywell Control Panels

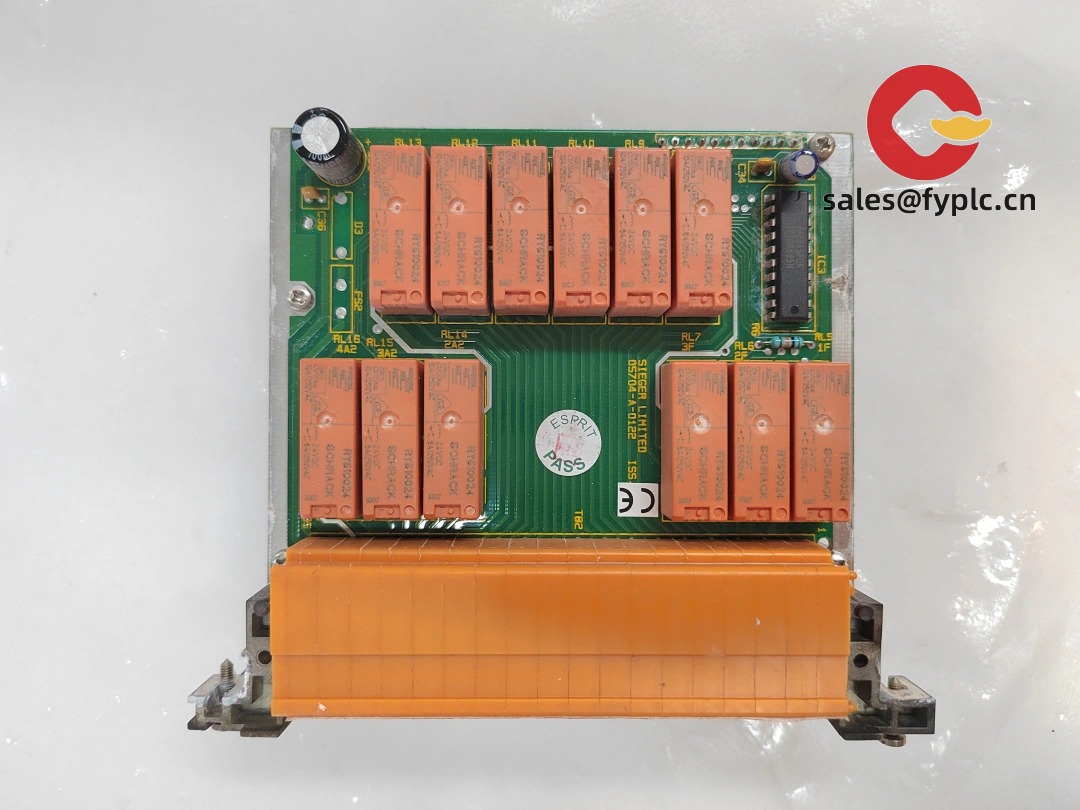

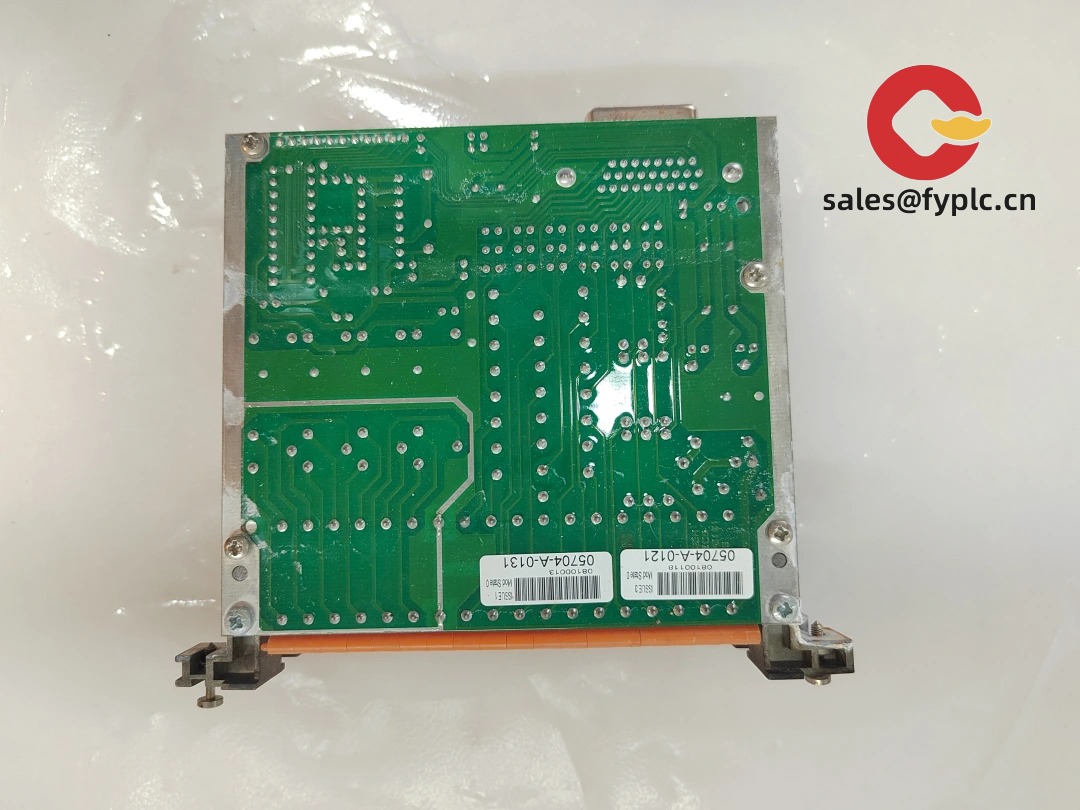

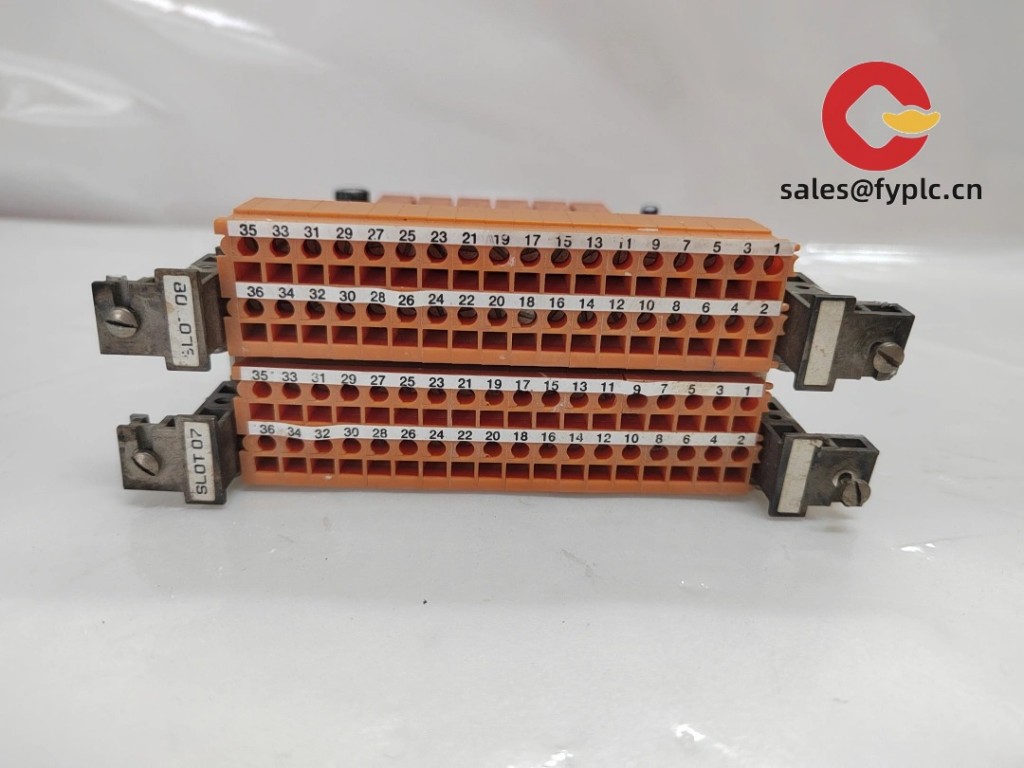

The HONEYWELL 0574-A-0121 and 0574-A-0131 form a matched wiring/adapter harness set used in Honeywell control/DCS panels. From my experience, plants stock these codes as direct, like‑for‑like replacements—when a connector gets damaged or a cable ages, you swap the harness and keep the original routing, pinout, and drawings intact. You might notice the keyed connectors and clear markings in the photos; that typically cuts continuity‑check time during short outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification, connector integrity check; ESD‑safe, shock‑resistant packing

Key Features

- OEM fit and pinout – Like‑for‑like harnesses for Honeywell control panels; typically no drawing or routing changes needed.

- Service‑friendly identification – Numbered conductors and keyed connectors reduce wiring errors during fast swaps.

- Shield/ground continuity – Built to maintain low‑noise signal paths for control and monitoring circuits.

- Rugged construction – Industrial‑grade cable jacket and strain relief for 24/7 cabinet environments.

- Panel‑ready lengths – Routing and bend radius suited to common Honeywell rack layouts and ducts.

Technical Specifications

| Brand / Model | HONEYWELL 0574-A-0121 / 0574-A-0131 |

| Product Category | OEM wiring/adapter harness set for Honeywell control/DCS panels |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment (final classification may vary by country) |

| Power Requirements | Passive component; no external power required |

| Signal I/O Types | Panel interconnects for control/monitoring signals; shielded pairs with ground continuity (variant‑dependent) |

| Communication Interfaces | None (harness connects via Honeywell panel connectors/terminals) |

| Dimensions & Weight | Harness lengths supplied for cabinet routing (commonly 0.5–2.0 m); ~0.1–0.4 kg set weight |

| Operating Temperature | Typically 0…+55 °C (cabinet‑installed; non‑condensing) |

| Installation Method | Route per Honeywell drawing; connect keyed plugs; torque terminals; maintain shield bonds and strain relief |

Application Fields

You’ll typically find these harnesses in Honeywell‑based cabinets where quick, predictable swaps matter:

- DCS/MCC panels in power, chemicals, refining, and pipelines.

- Process skids and utility panels standardized on Honeywell hardware.

- Brownfield upgrades—preserve existing drawings, pinouts, and cable routes.

- OEM machines using Honeywell panel connectors for faster assembly and FAT.

A site tech told me last month, “We matched the 0574‑A‑0121/0131 codes, routed the harness along the original ties, and continuity checked clean in under 20 minutes.” That seems to be the usual rhythm with these sets.

Advantages & Value

- Reliability – OEM‑spec shielding and terminations reduce intermittent faults.

- Compatibility – Direct fit with Honeywell connectors and panel geometry; minimal rework.

- Cost savings – Faster swap‑outs shorten outage time and avoid rewiring.

- Support – We can help confirm interchange codes, connector style, and length before shipment.

- Logistics – Practical lead times and protected packaging to keep installs on schedule.

Installation & Maintenance

- Cable routing: Follow the original harness path; maintain bend radius; use strain relief and tie points.

- EMC practice: Keep low‑level pairs away from VFD/motor leads; ensure 360° shield bonds at panel entry.

- Continuity check: Verify pin‑to‑pin and shield continuity after install; document results with panel records.

- ESD & handling: Handle connectors gently; cap unused ends; store spares in ESD‑safe bags.

- Routine care: Inspect tie points and connector latches during PMs; replace if jacket abrasion or latch wear is observed.

Quality & Certifications

- Manufactured to Honeywell quality standards, typically aligned with ISO 9001.

- CE applicability depends on the assembly; system compliance handled at the panel level.

- RoHS status may vary by build; we can confirm by part/serial on request.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.