Description

Allen‑Bradley 700-PKT_B – Accessory/Terminal Kit for Bulletin 700‑P Industrial Control Relays

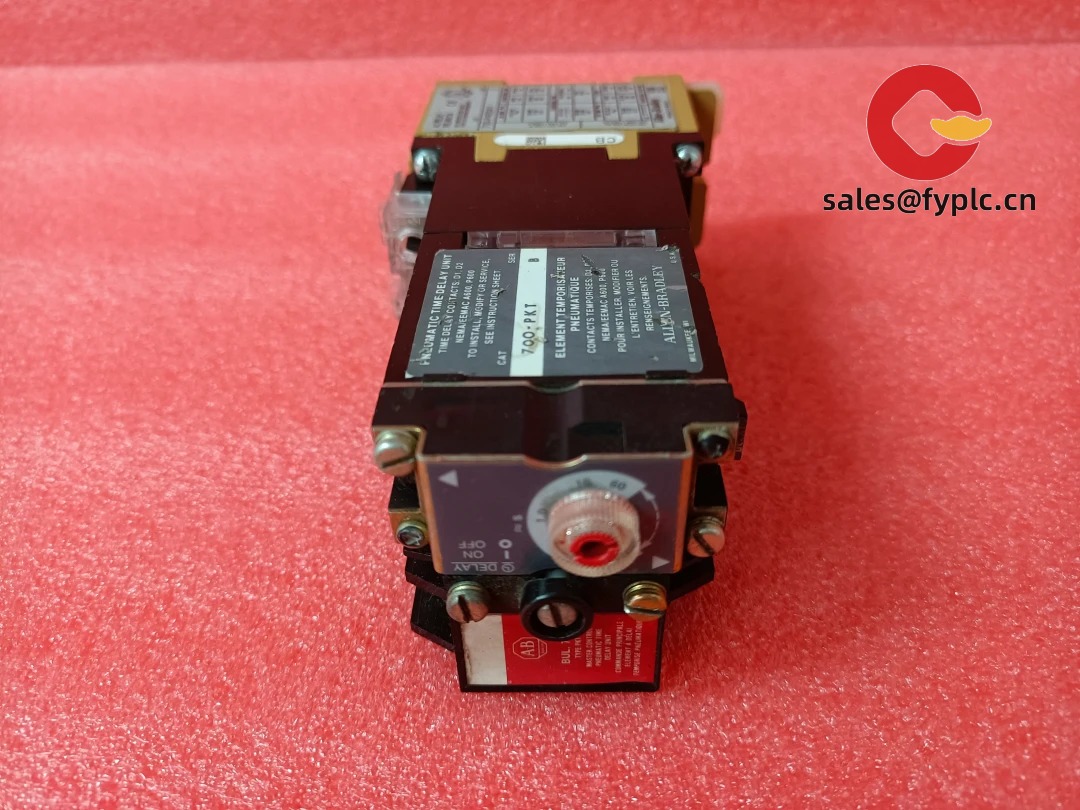

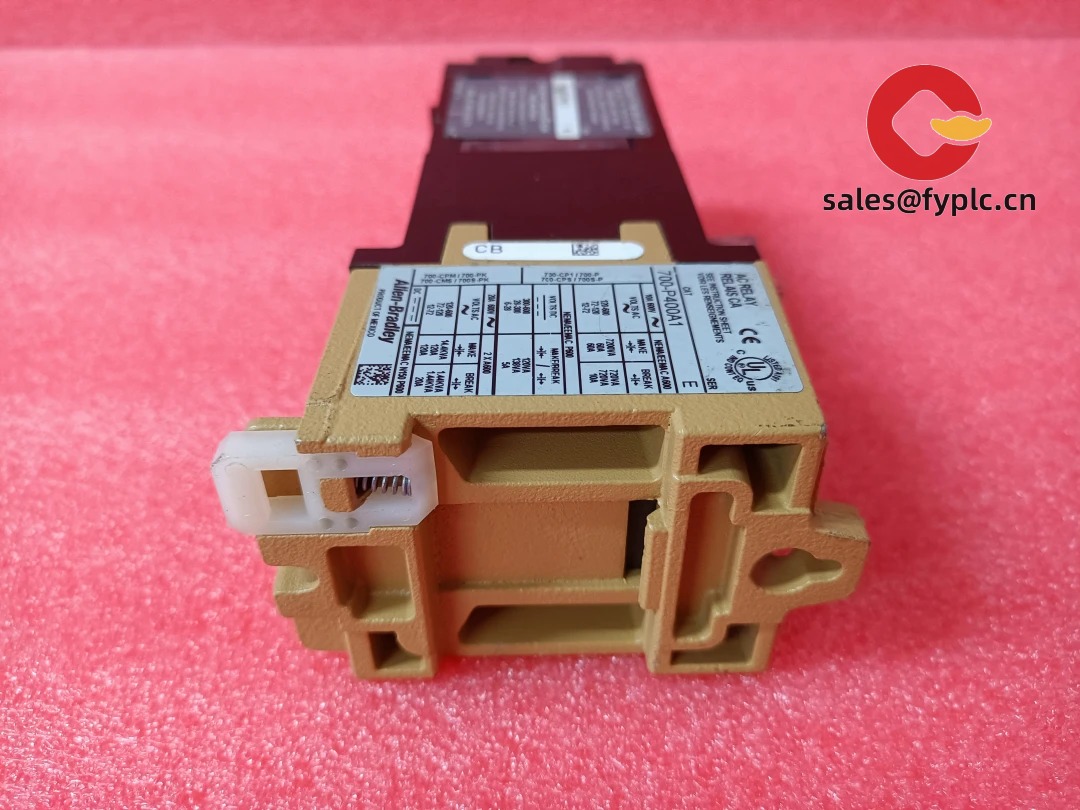

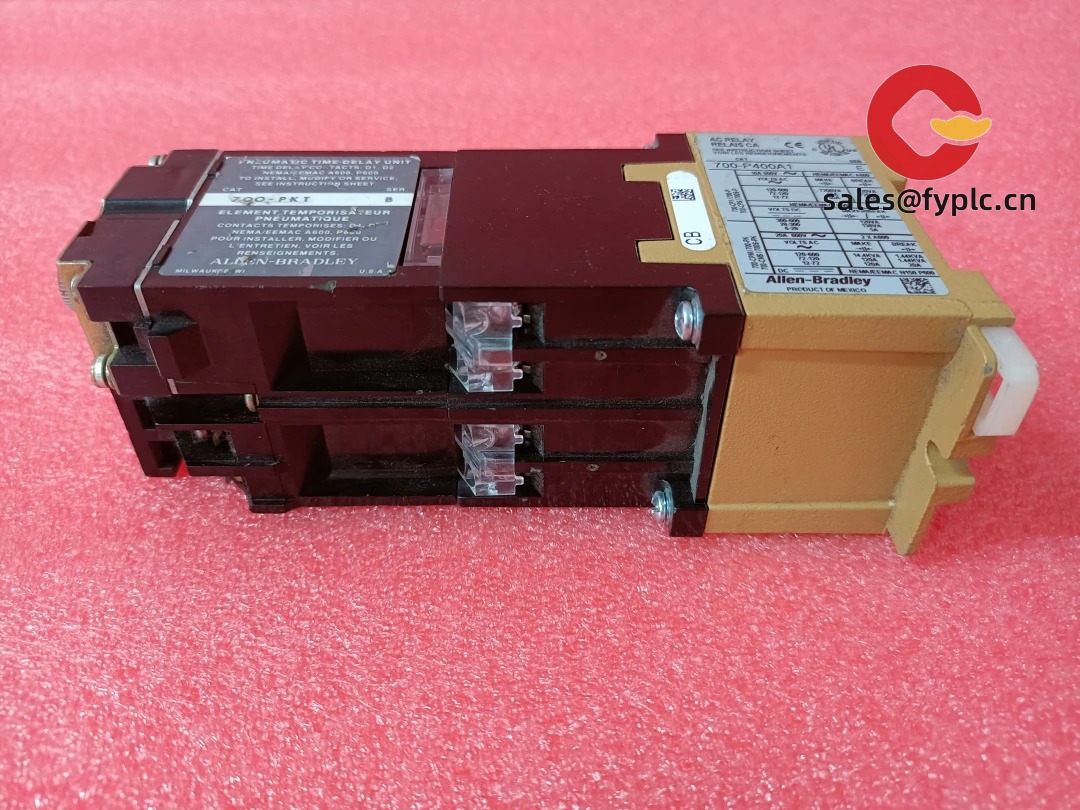

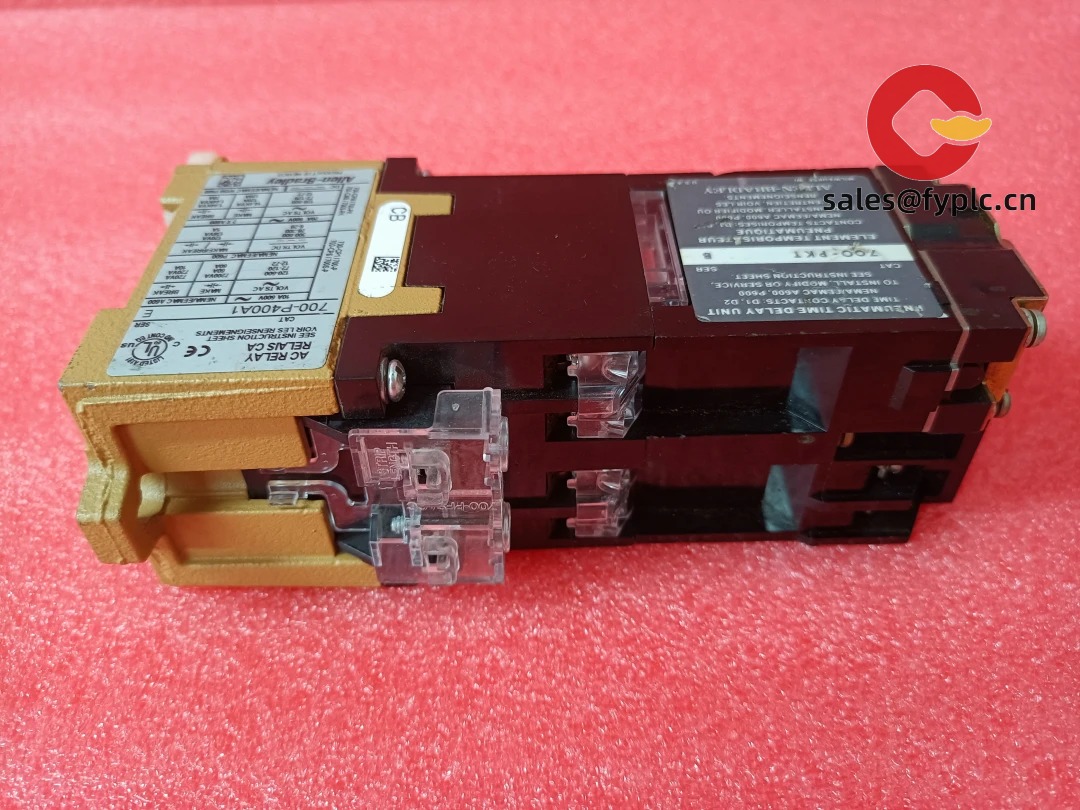

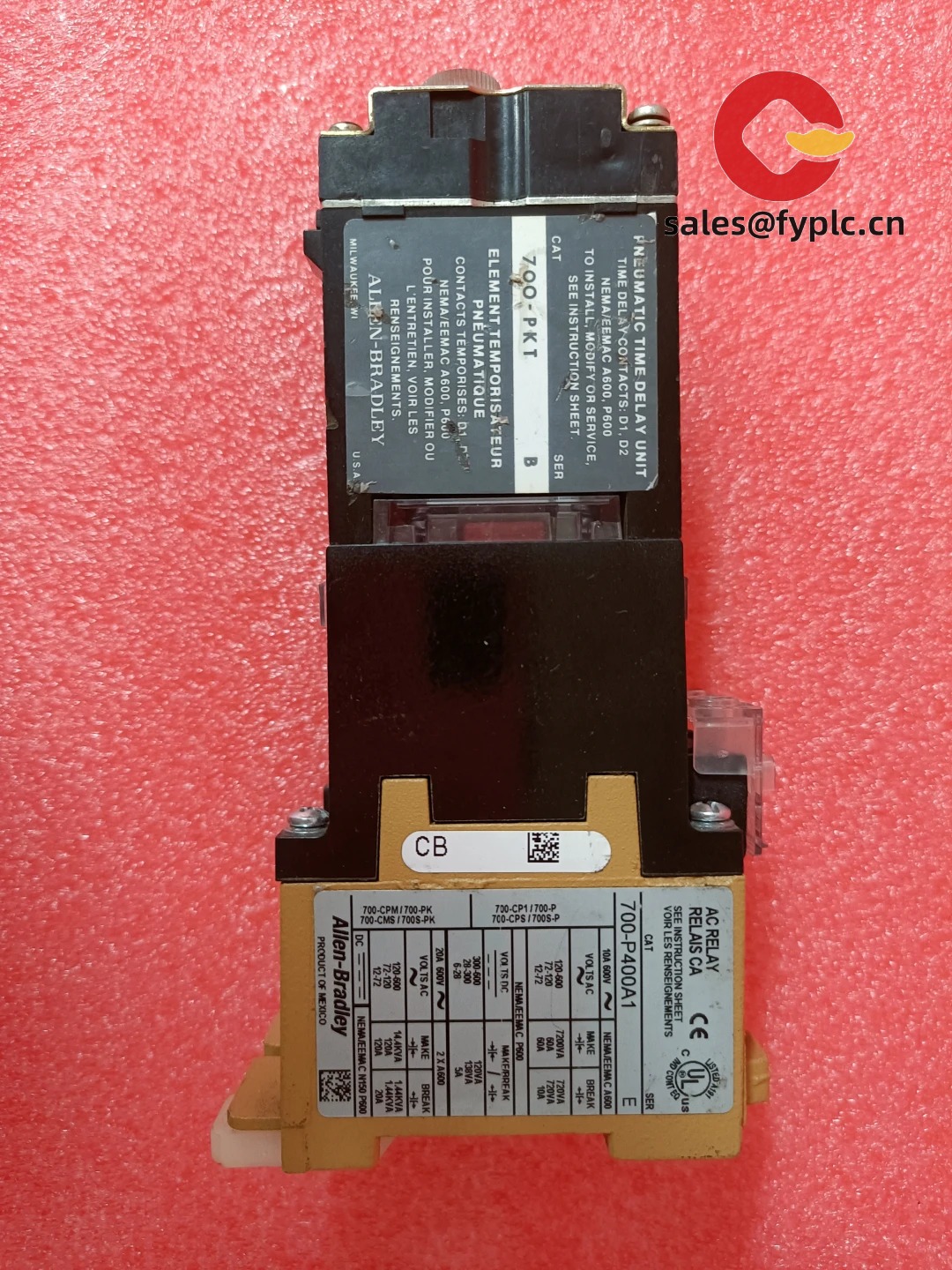

The Allen‑Bradley 700-PKT_B appears to be an accessory/terminal kit for Bulletin 700‑P relays, used to simplify wiring and provide a clean, service‑friendly interface in control panels. From my experience, maintenance teams keep these kits on hand because they make relay swaps predictable—land your conductors once, label clearly, and you’re back online without reworking the whole terminal strip. You might notice the finger‑safe styling and clear markings in the photos; that typically cuts commissioning time and reduces wiring errors during short outages.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and connector integrity check; ESD‑safe, shock‑resistant packing

Key Features

- Purpose‑built for Bulletin 700‑P relays – Provides a tidy, consistent wiring interface for relay contacts and coil terminations.

- Finger‑safe, panel‑ready – Shrouded terminals and clear markings typically help meet shop safety and QA practices.

- Service‑friendly identification – Label areas and terminal numbering reduce mistakes during maintenance windows.

- Passive accessory – No separate power; simply installs with the relay hardware in the cabinet.

- Drop‑in retrofit – In most cases, fits existing 700‑P mounting without re‑routing wires or redesigning the panel.

Technical Specifications

| Brand / Model | Allen‑Bradley (A‑B) 700-PKT_B |

| Product Type | Accessory / terminal kit for Bulletin 700‑P industrial control relays |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment (final classification may vary by country) |

| Power Requirements | Passive component; no external power required |

| Signal Input/Output Types | Terminal interface for relay coil and contact wiring (screw/clamp style, variant‑dependent) |

| Communication Interfaces | None (mechanical/electrical termination accessory) |

| Installation Method | Mount/attach with the 700‑P relay in a control cabinet; route conductors per panel drawing; torque terminals to spec |

| Operating Temperature | Cabinet‑installed; typically 0…+55 °C (non‑condensing) |

Application Fields

You’ll typically see 700‑PKT accessories used wherever 700‑P relays are standard and tidy wiring matters:

- Packaging and material handling panels—clean relay terminations and fast service swaps.

- Water & wastewater cabinets—finger‑safe wiring around dense I/O.

- Power & utilities skids—consistent terminal layout across replicated panels.

- OEM machines—repeatable build with labeled relay interfaces for FAT and field service.

A panel builder put it simply: “We standardized on the PKT kit, and relay changeovers dropped to minutes—labels lined up, no guesswork.” That matches what I’ve seen on most brownfield upgrades too.

Advantages & Value

- Reliability – Solid, finger‑safe terminations cut intermittent faults from loose wiring.

- Compatibility – Built for 700‑P relays; keeps cabinet drawings and wiring routes consistent.

- Cost control – Faster installs and swap‑outs reduce downtime and assembly hours.

- Support – We can help confirm compatibility with your 700‑P relay variant before your maintenance window.

- Logistics – Practical lead times and protected packing to keep the panel work clean.

Installation & Maintenance

- Wiring practice: Separate control wiring from motor/VFD leads; maintain shield bonds where specified.

- Torque & identification: Tighten terminals to spec; apply circuit labels so future swap‑outs are traceable.

- Panel standards: Keep ambient typically 0…55 °C; use strain relief and tidy routing to avoid conductor stress.

- Routine care: Re‑torque terminals during PMs; check for jacket abrasion and replace if any damage is noticed.

- Spares strategy: Keeping one kit per cabinet is, in most cases, cheap insurance against unplanned stops.

Quality & Certifications

- Manufactured to Rockwell Automation/Allen‑Bradley quality standards (ISO 9001 aligned).

- System compliance (CE/UL) is typically at the panel level; accessory components follow applicable standards.

- RoHS status depends on production lot; we can verify by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.