Description

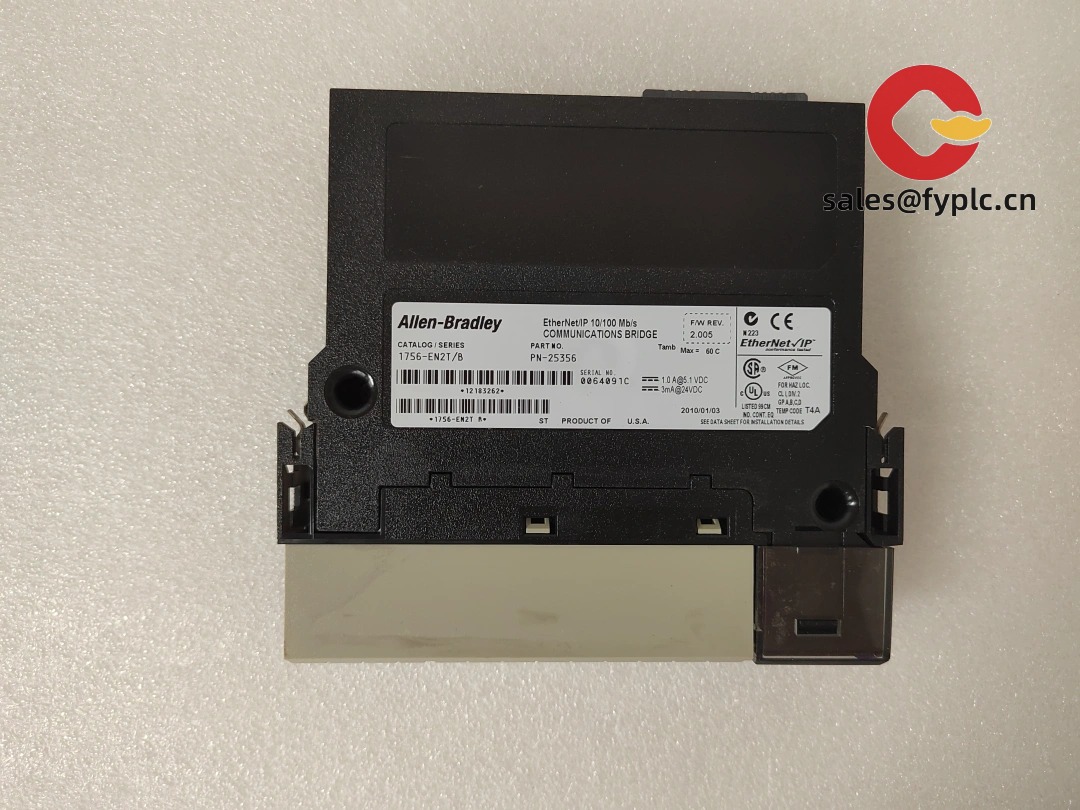

Allen‑Bradley 1756‑EN2T_B – ControlLogix EtherNet/IP Bridge Module (Series B) for High‑Performance I/O and SCADA Networking

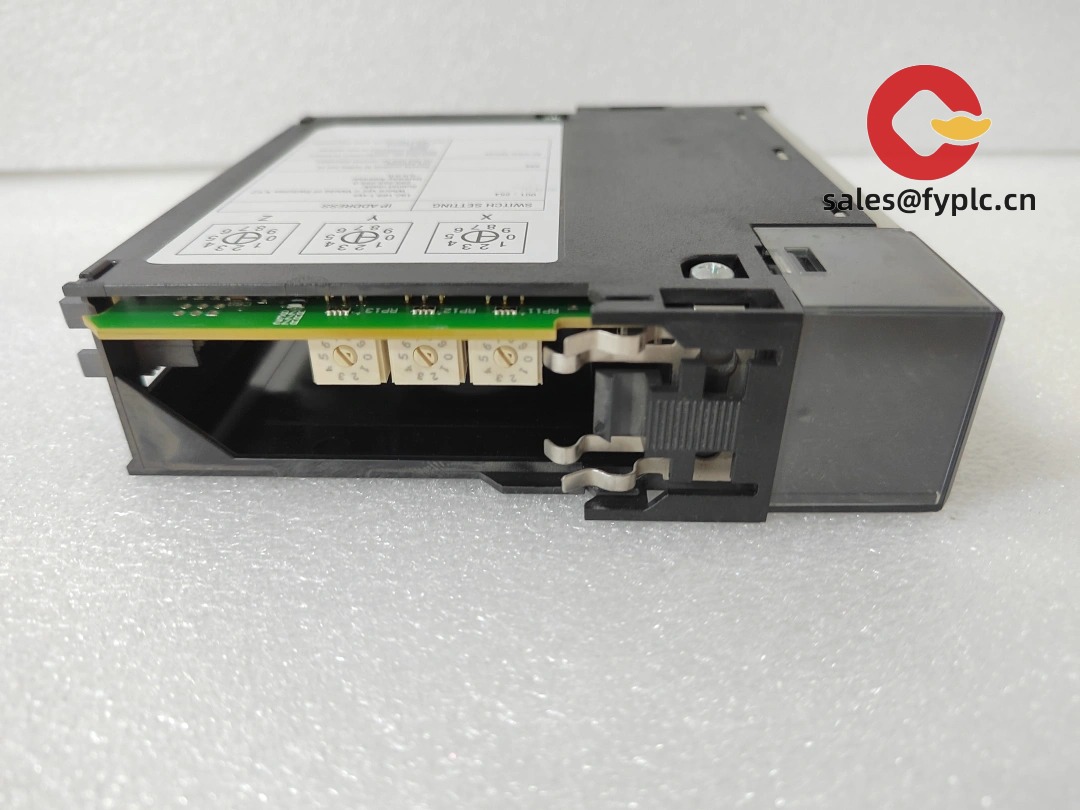

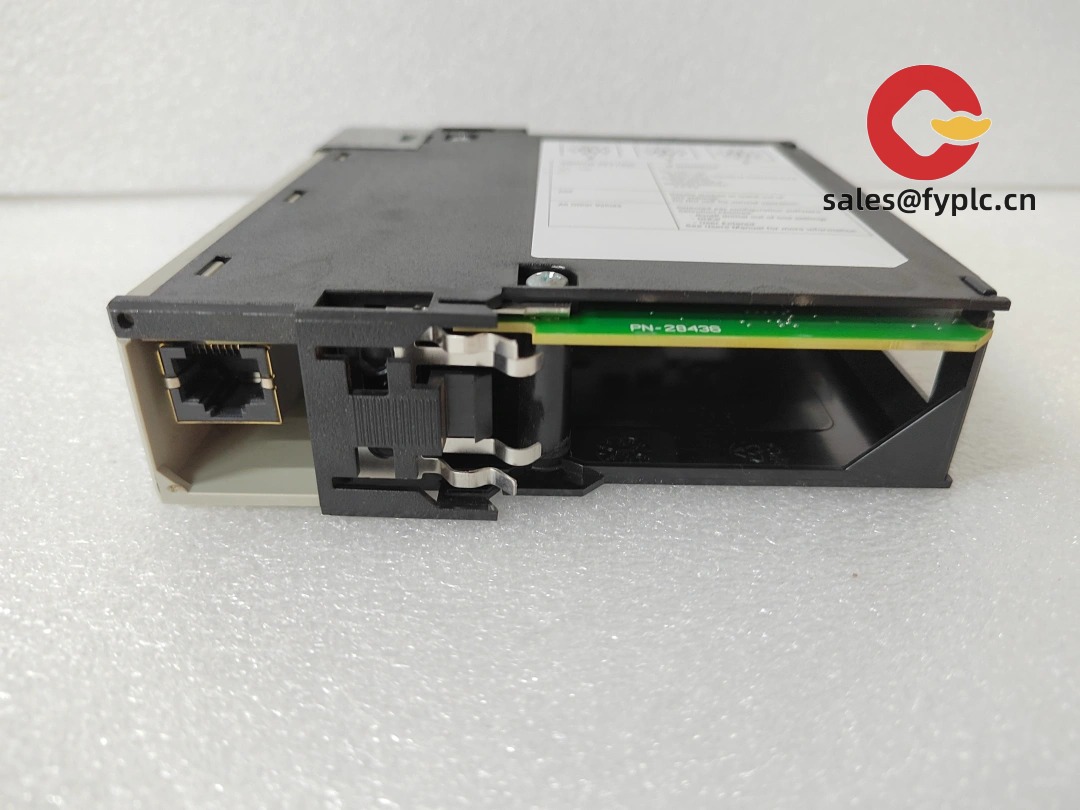

The 1756‑EN2T_B is a single‑port EtherNet/IP communication module for ControlLogix racks. From my experience, it’s the go‑to step up from older ENBT cards when you need faster updates, more connections, and cleaner diagnostics—without changing your cabinet layout. You might notice the single RJ‑45 on the front and the status LEDs; addressing is quick with BootP/DHCP or a static IP, and the built‑in web pages make health checks straightforward during short maintenance windows.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express methods: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification and port integrity; ESD‑safe, shock‑resistant packing

Key Features

- High‑performance EtherNet/IP – Faster I/O update rates and higher connection capacity than legacy ENBT modules.

- Single RJ‑45 port – 10/100/1000 Mbps copper for star/linear topologies with standard switches.

- Built‑in diagnostics – Embedded web pages typically show connections, module health, and packet statistics.

- Time sync & producer/consumer – Supports CIP data models; time synchronization available on select revisions (check firmware notes).

- Studio 5000 integration – Add‑On Profiles and familiar tag structures make commissioning predictable.

- Backplane bridge – Routes data between EtherNet/IP networks and the ControlLogix backplane for controllers and I/O.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756‑EN2T_B (Series B) |

| Network | EtherNet/IP, 10/100/1000 Mbps, 1 × RJ‑45 (copper) |

| Backplane | ControlLogix 1756 backplane bridge to controller/I/O |

| Addressing / Setup | Static IP or BootP/DHCP; configuration via Studio 5000 and module web pages (where enabled) |

| HS Code (reference) | 8538.90 – Parts suitable for electrical control equipment |

| Power Requirements | Powered via 1756 backplane (no external power on module) |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

| Installation Method | Single‑slot 1756 chassis; connect RJ‑45 to managed switch; follow grounding/EMC best practices |

Application Fields

Where I’ve seen the 1756‑EN2T_B deliver the most value:

- Remote EtherNet/IP I/O and drives on packaging and materials handling lines.

- Process skids and MCCs that need deterministic RPIs with higher connection counts.

- Brownfield upgrades replacing ENBT modules for better throughput and diagnostics.

- SCADA/HMI consolidation where one bridge serves I/O, HMIs, and peer controllers.

A controls tech told me, “We dropped in the EN2T, set the IP over BootP, and our I/O updates halved—web diagnostics made it easy to verify.” That seems to be the typical experience when the switch is configured cleanly.

Advantages & Value

- Reliability – Proven 24/7 operation with clear status indicators and onboard diagnostics.

- Compatibility – Native to ControlLogix; plays nicely with managed switches and standard EtherNet/IP devices.

- Performance uplift – Faster updates and more headroom than legacy bridges, typically without cabinet changes.

- Cost control – Drop‑in retrofit extends installed systems; avoids re‑engineering I/O networks.

- Support – We can help with firmware alignment, IP planning, and RPI tuning before your outage window.

Installation & Maintenance

- Networking: Use managed switches with IGMP Snooping/Querier for multicast; segregate control VLANs to keep traffic predictable.

- Cabling: Shielded CAT5e/6; maintain bend radius; avoid routing alongside VFD motor leads.

- Addressing: Reserve IPs and document in the panel; disable BootP after assigning a static address.

- Firmware: Match controller/project expectations; ControlFLASH/Studio 5000 typically handles updates.

- Diagnostics: Use the module web pages and Logix tags to monitor connection health, packet errors, and module temperature.

- Routine care: Periodic dust removal, re‑torque chassis mounting, and a quick review of network counters during PMs.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE/UL/cUL markings apply at the module/system level per Rockwell documentation.

- RoHS status depends on series/lot; we can confirm by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.