Description

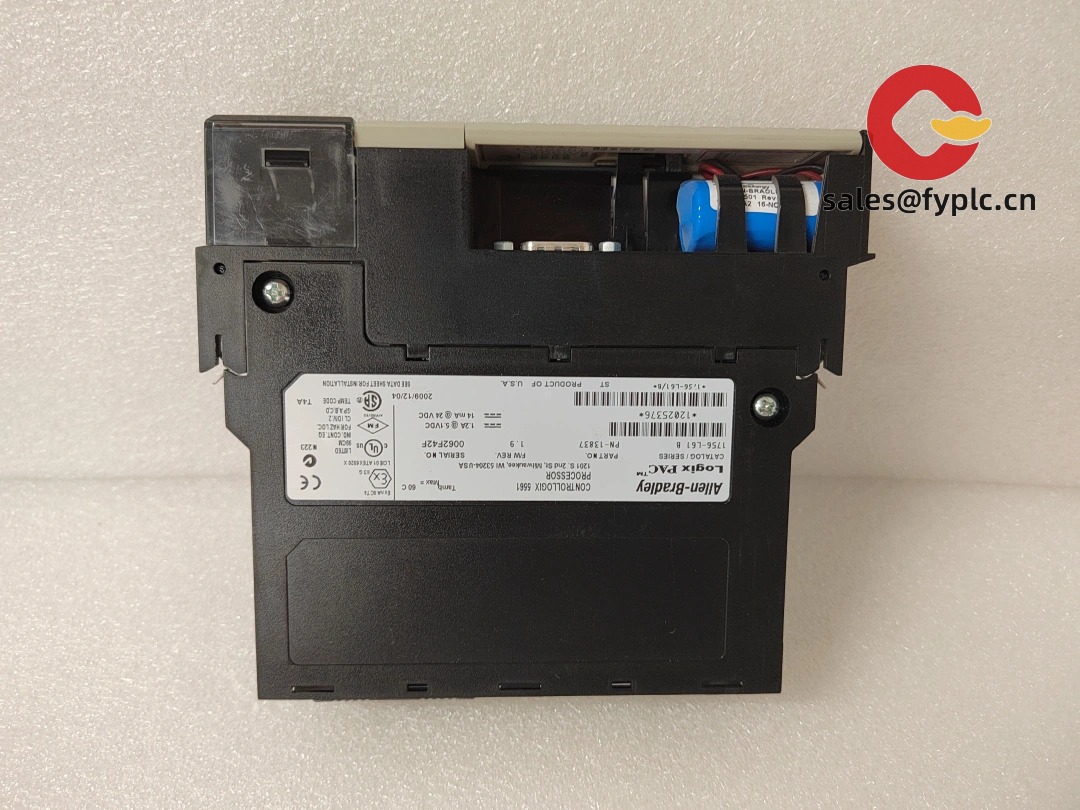

Allen‑Bradley 1756‑L61_B – ControlLogix Logix5561 CPU (Series B) for Proven, Scan‑Based Control

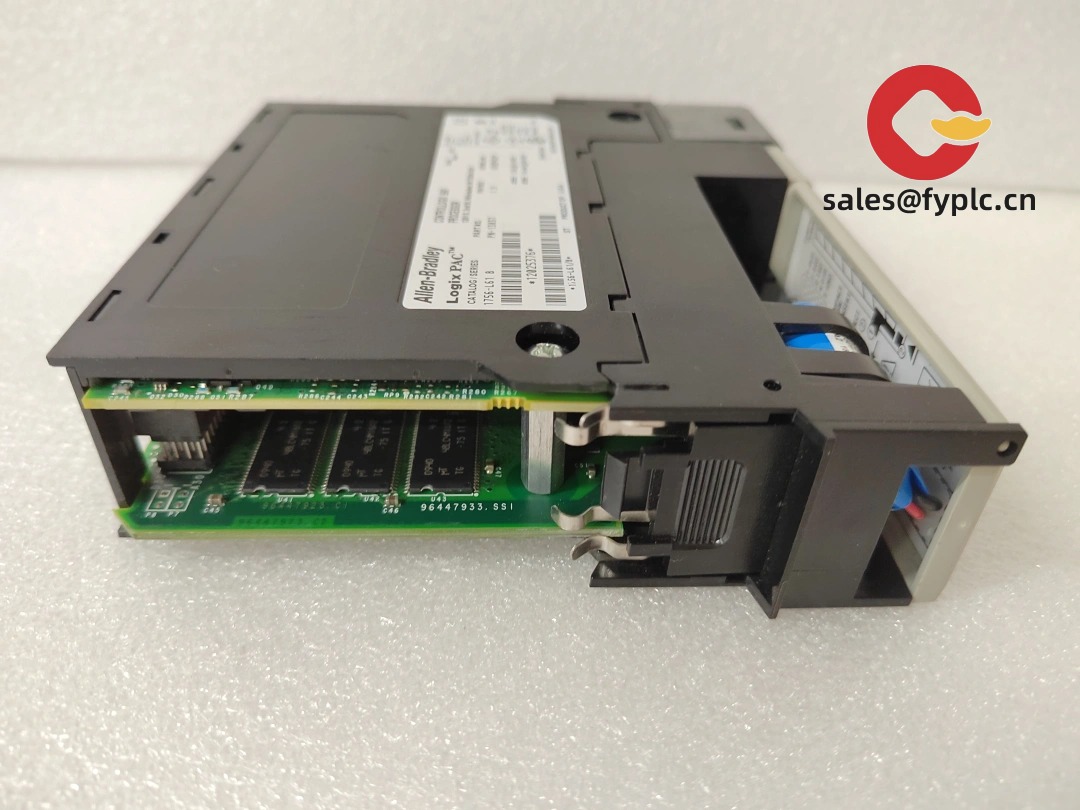

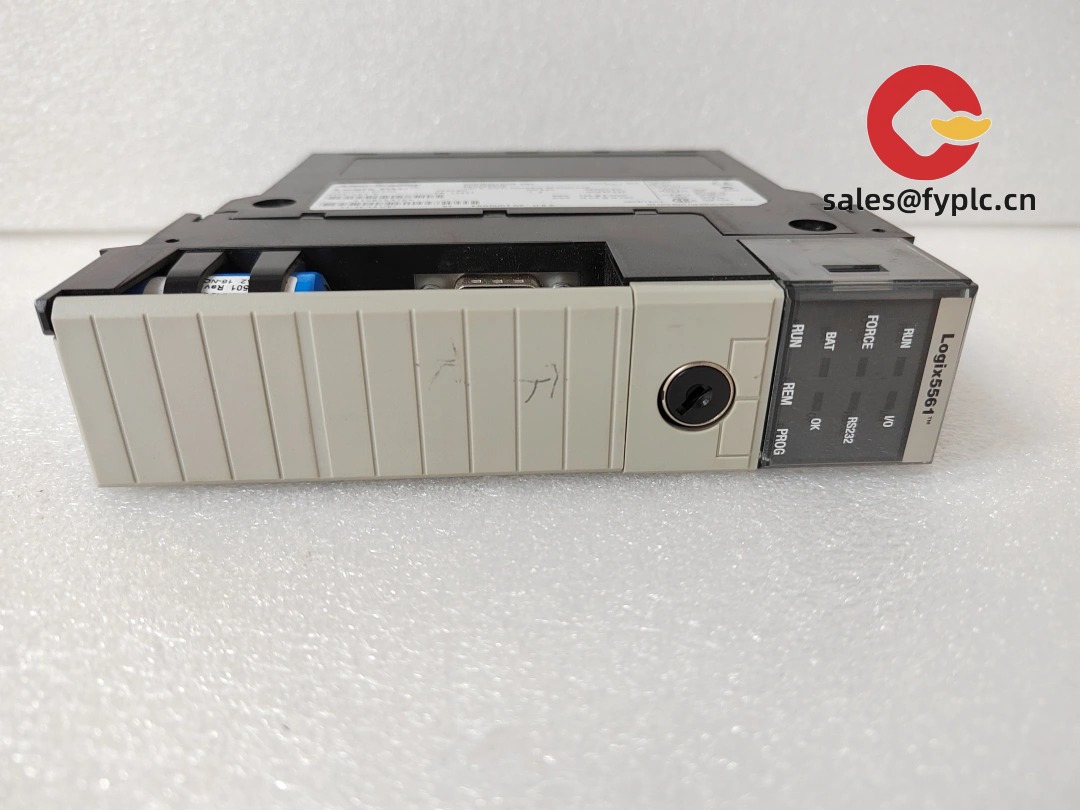

The Allen‑Bradley 1756‑L61_B is a Logix5561 controller for ControlLogix systems. From my experience, it’s the dependable “workhorse” CPU many plants standardize on when they want stable scan behavior, broad module compatibility, and straightforward maintenance. You might notice the RS‑232 port on the front and the CompactFlash slot—both are handy in brownfield panels where a quick program backup or a serial maintenance link still makes life easier.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and basic functional check; ESD‑safe, shock‑resistant packing

Key Features

- 2 MB user memory – Adequate space for medium‑to‑large applications without pushing scan times.

- Front RS‑232 serial port – DF1/ASCII for commissioning, maintenance tools, or legacy links.

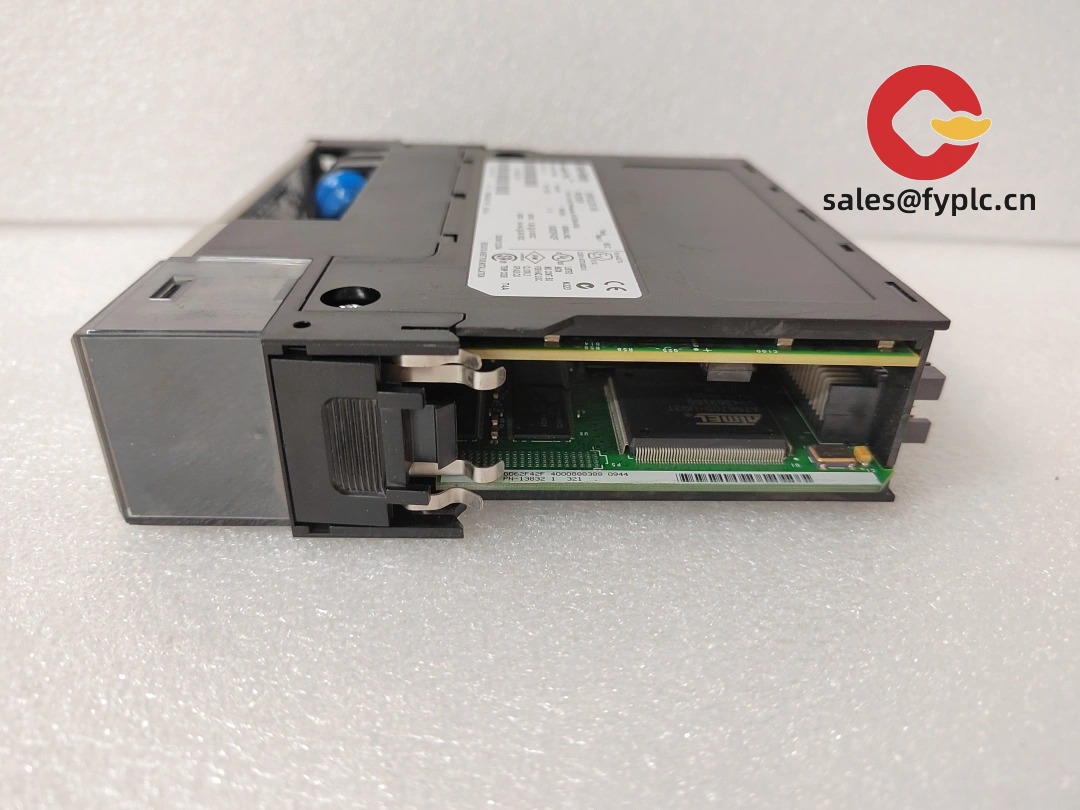

- CompactFlash slot – Removable non‑volatile storage for program backup and fast field recovery.

- Backplane‑centric design – Add EtherNet/IP, ControlNet, or other networks via 1756 comm modules; keeps the CPU lean and flexible.

- Redundancy capable – Supports ControlLogix redundancy in many deployments (firmware/architecture dependent).

- 24/7 duty pedigree – Series B mechanics and diagnostics that, in many cases, run for years with minimal intervention.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756‑L61_B (Logix5561, Series B) |

| User Memory | 2 MB (controller program and data) |

| Non‑volatile Storage | CompactFlash (1784‑CF series), slot on front panel |

| Front Ports | 1 × RS‑232 (DB9) DF1/ASCII; network access via separate 1756 comm modules |

| HS Code | 8537.10 – Programmable controllers (reference; final classification may vary by country) |

| Power Requirements | Powered via 1756 backplane (no external power at the CPU) |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

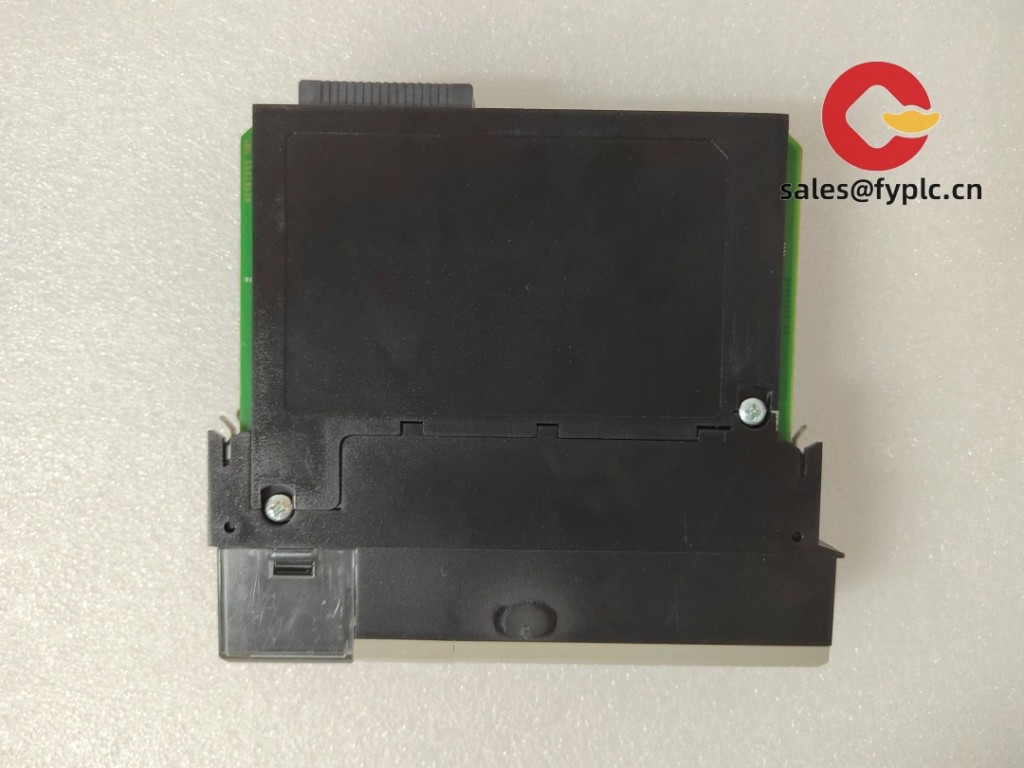

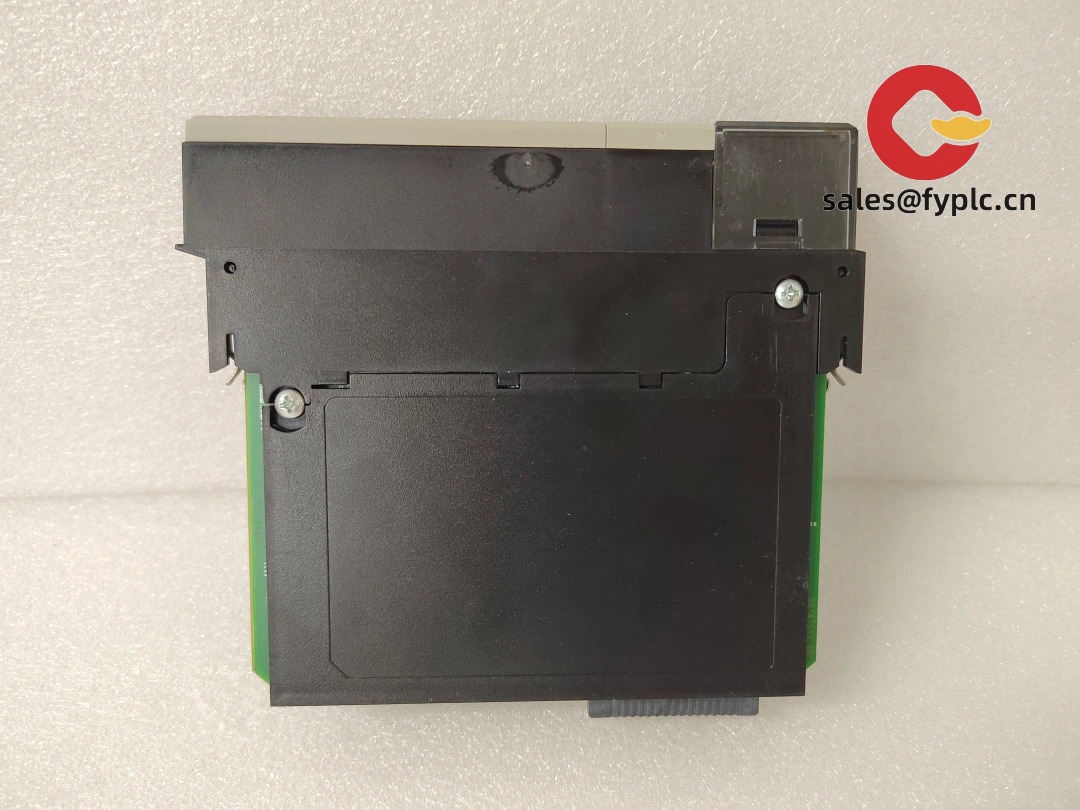

| Dimensions & Weight (approx.) | ~145 × 35 × 140 mm; ~0.35–0.55 kg (single‑slot 1756 form factor) |

| Installation Method | Insert into 1756 chassis; battery installed on controller; CompactFlash optional |

Application Fields

Where this CPU tends to shine in daily service:

- Packaging and material handling cells needing steady scan times and simple diagnostics.

- Utilities and water—distributed ControlLogix racks tied back over EtherNet/IP or ControlNet.

- Process skids—clean integration with 1756 analog/temperature/tech modules.

- Brownfield upgrades—drop‑in CPU replacement that preserves wiring and I/O layout.

One thing I appreciate is how predictable the swap feels. A controls tech told me, “We dropped in the L61, loaded the project from CF, and the line was back in step by the next hour.” That’s been typical when firmware and module revisions are lined up beforehand.

Advantages & Value

- Reliability – Proven 24/7 operation; stable scan and clear status indications.

- Compatibility – Works with the broad ControlLogix ecosystem of I/O and network modules.

- Serviceability – CompactFlash backup and a front serial port make field support straightforward.

- Cost control – Extends installed bases without cabinet redesign or control philosophy changes.

- Support – We can help verify firmware targets, redundancy plans, and memory headroom before your window.

Installation & Maintenance

- Panel practices: Mount the 1756 chassis in a ventilated enclosure; bond to ground; keep ambient typically 0…60 °C.

- Project handling: Align controller firmware with the project; keep a CompactFlash backup and a recent ACD on hand.

- Battery & clock: Check battery status (RTC/memory retention) and replace per maintenance plan.

- Networking: Add comm modules (ENxT/CN2x) as needed; document slot addressing to cut troubleshooting time.

- Routine care: Periodic dust removal, connector re‑seat checks, and a quick review of controller diagnostics during PMs.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE/UL/cUL markings apply at the module/system level per Rockwell documentation.

- RoHS status depends on series/lot; we can confirm by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.