Description

Allen‑Bradley 1756‑PA72_C – ControlLogix AC Power Supply for Stable 1756 Backplane Power (Series C)

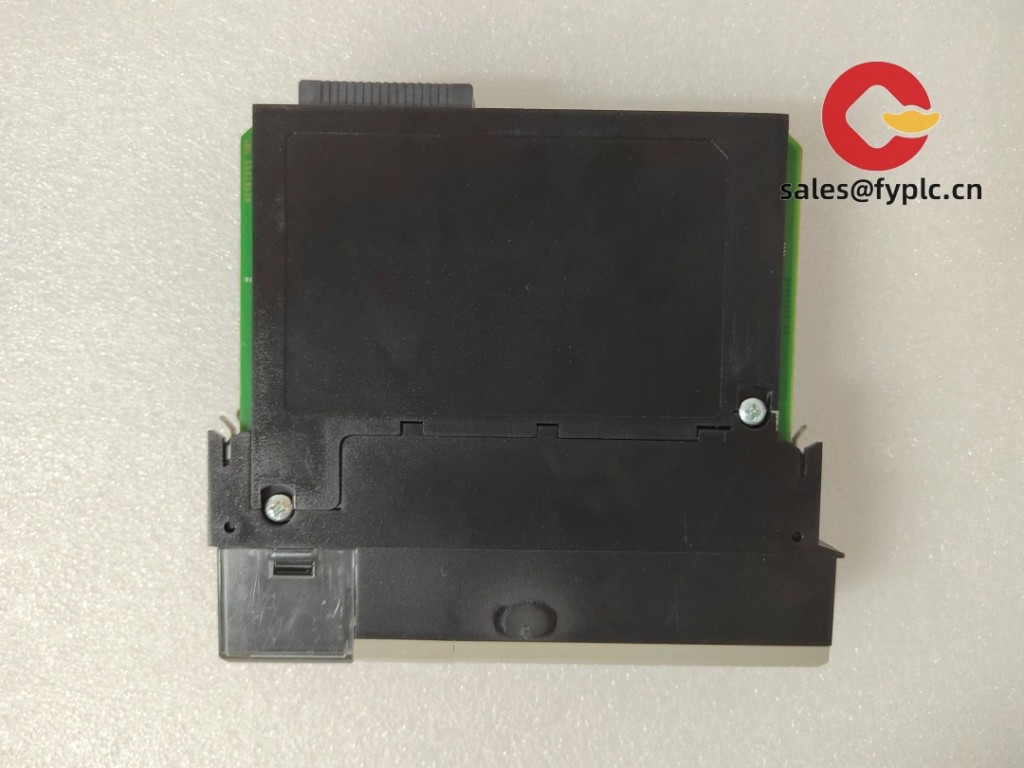

The Allen‑Bradley 1756‑PA72_C is the AC power supply that mounts on the left end of a ControlLogix chassis and delivers regulated backplane power for your controller, comms, and I/O modules. From my experience, plants keep a PA72 on the shelf because it’s a straight, no‑drama swap when a rack won’t power cleanly—move the mains leads, check the LEDs, and your 1756 rack typically comes back up without touching the I/O cards. You might notice the sturdy terminal cover and clear status indicators, which make commissioning checks quick during short outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment checks: visual/label verification, terminal cover/LED check; ESD‑safe, shock‑resistant packing

Key Features

- Universal AC input – Accepts typical industrial mains (approximately 85…265 VAC, 47–63 Hz) for global panels.

- Clean backplane power – Provides the 1756 chassis rails (5.1 V and 24 V) used by ControlLogix CPUs, comms, and I/O.

- Left‑end mount – Attaches directly to the left side of any ControlLogix chassis for a tidy, service‑friendly layout.

- Status at a glance – Front LEDs help you verify input presence and backplane health in seconds.

- Protection built‑in – Overload/thermal protections designed for 24/7 duty in real‑world cabinets.

- Series C mechanics – Robust terminal cover and grounding points; in many cases reduces nuisance resets from vibration.

Technical Specifications

| Brand / Model | Allen‑Bradley 1756‑PA72_C (ControlLogix, Series C) |

| Function | AC power supply for 1756 chassis backplane (CPU, comms, and I/O power) |

| HS Code (reference) | 8504.40 – Static converters / power supplies (final classification may vary by country) |

| Mains Input | Typically 85…265 VAC, 47–63 Hz (check nameplate for site‑specific ratings) |

| Backplane Output | Regulated 5.1 V and 24 V chassis rails; size load per Rockwell 1756 power budget rules |

| Communication Interfaces | None (power module; status via front indicators) |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

| Dimensions & Weight (approx.) | 1756 power‑supply form factor; ~145 × 70 × 140 mm; ~0.8–1.2 kg |

| Installation Method | Mounts on left end of 1756 chassis; land AC mains on front terminals; bond to panel ground |

Application Fields

You’ll typically find the 1756‑PA72_C in ControlLogix racks that need dependable backplane power:

- OEM skids and packaged systems where rack uptime is critical.

- Utilities and water—distributed 1756 panels in MCCs and process rooms.

- Process plants—brownfield upgrades keeping the existing chassis and module layout.

- Material handling and F&B lines—simple, predictable rack power with clear LED status.

A plant electrician told me, “We moved the mains leads to the new PA72, checked the LEDs, and the controller booted clean in minutes.” That’s been the usual experience when the power budget and grounding are set right.

Advantages & Value

- Reliability – Stable backplane rails for 24/7 operation; fewer nuisance resets when wiring is tidy.

- Compatibility – Native fit for 1756 chassis; preserves cabinet layout and existing module stack‑up.

- Cost control – Drop‑in replacement that avoids re‑engineering the rack or I/O.

- Serviceability – Simple terminals, clear LEDs, and straightforward mounting shorten maintenance windows.

- Support – We can help confirm input rating, grounding, and power budget before your window.

Installation & Maintenance

- Mains wiring: Use appropriately rated conductors, fusing, and earth; verify the input range on the nameplate.

- Power budget: Sum the backplane draw of all 1756 modules; maintain margin per Rockwell’s sizing guide.

- EMC & grounding: Bond the chassis to panel ground; route AC away from low‑level analog and network cabling.

- Commissioning: Check front LEDs for input/backplane OK; confirm the controller boots and diagnostics are clear.

- Routine care: Periodic dust cleaning, terminal re‑torque, and a quick log of input voltage and rack load during PMs.

- Spares strategy: Keeping one PA72 on the shelf is, in most cases, cheap insurance against unplanned rack outages.

Quality & Certifications

- Manufactured under Rockwell Automation quality systems (ISO 9001 aligned).

- CE/UL/cUL conformity applies at the system/module level per Rockwell documentation.

- RoHS status depends on production lot; we can confirm by part/serial if needed.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.