Description

Bently Nevada 1900/65A (167699-02) – General‑Purpose Machinery Condition Monitor Module

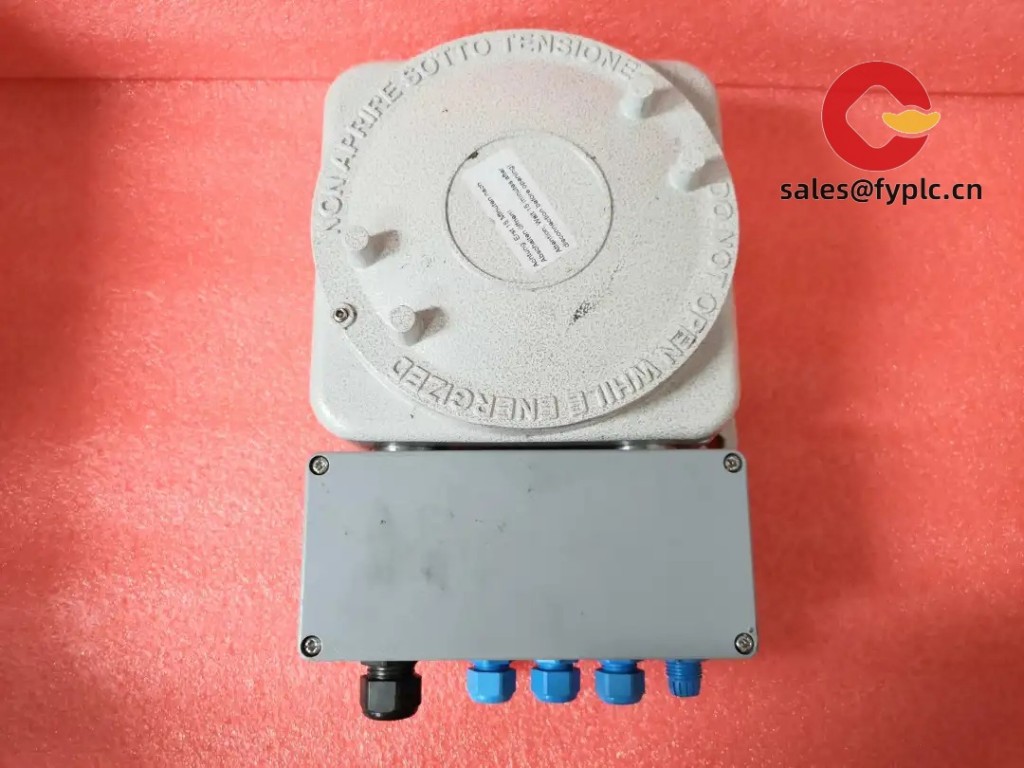

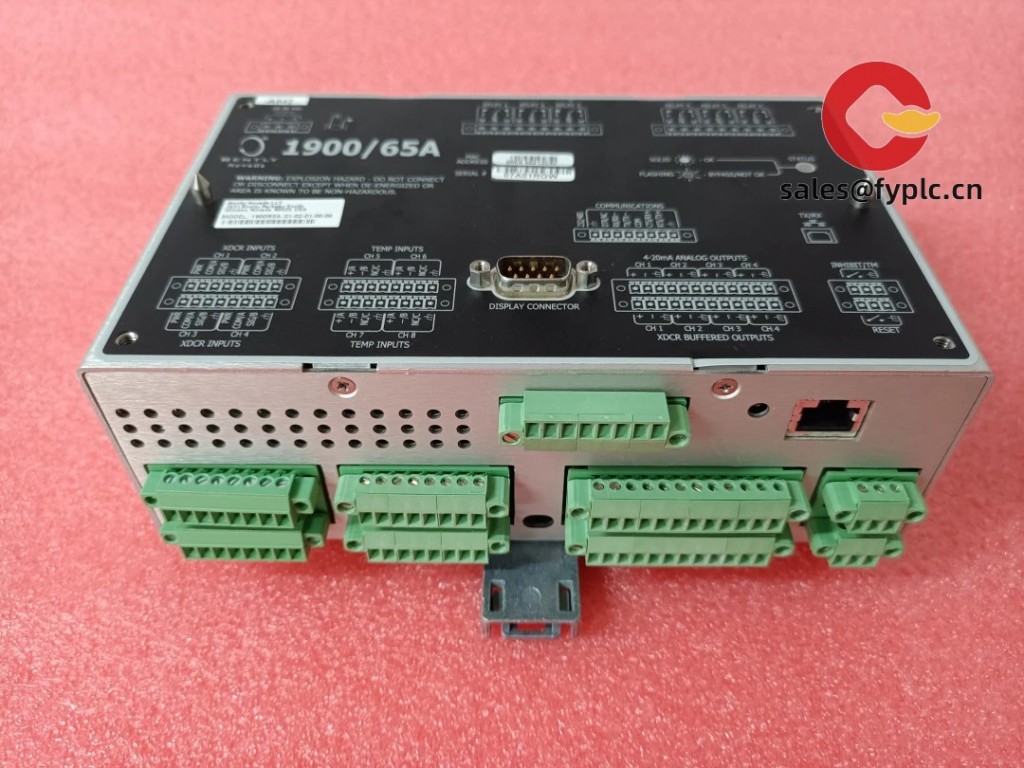

The code 167699-02 corresponds to a Bently Nevada 1900/65A series module used for continuous machinery protection and basic condition monitoring. From my experience, plants deploy this unit on individual pumps, fans, blowers, or gearboxes where you want reliable trip logic, 4–20 mA trends to the DCS, and easy field diagnostics—without the footprint of a full rack system. You might notice the compact, panel‑mount form factor and clear labeling; swaps and commissioning tend to be predictable when the variant code matches the installed base.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

- Pre‑shipment: visual/label verification and basic functional/LED check; ESD‑safe, shock‑resistant packing

Key Features

- Dedicated machine protection – Continuous monitoring with trip/alarm logic for rotating assets.

- 4–20 mA outputs – Analog trends for DCS/PLC historians; simple to integrate and troubleshoot.

- Relay contacts – Alarm/trip relays for interlocks and permissives (variant‑dependent).

- Transducer flexibility – Typically supports eddy current probes, accelerometers/velocity (per module option); buffered outputs are common on this family.

- Compact panel form factor – Fits easily in MCC/process cabinets; straightforward terminal access for commissioning.

- Variant identification – The “167699‑02” build code helps match channel options and I/O behavior already validated at site.

Technical Specifications

| Brand / Model | Bently Nevada 1900/65A – 167699‑02 |

| Function | General‑purpose machinery monitor with alarms/trips and 4–20 mA outputs |

| HS Code (reference) | 9031.80 – Measuring/monitoring instruments (final classification may vary by country) |

| Power Requirements | Typically 24 V DC control power (check nameplate for exact range) |

| Signal I/O Types | Transducer inputs (e.g., proximity probe or accelerometer), 4–20 mA outputs, alarm/trip relays; buffered output often available (variant‑dependent) |

| Communication Interfaces | Local terminals; some 1900/65A variants support basic serial/Modbus—confirm by build code |

| Dimensions & Weight (approx.) | Compact panel module; ~200 × 120 × 45 mm; ~0.5–0.8 kg (typical for this family) |

| Operating Temperature | Typically 0…+60 °C (enclosure‑installed; non‑condensing) |

| Installation Method | Panel/mounting plate installation in a grounded cabinet; shielded wiring to sensor and control system |

Application Fields

Where this module typically earns its keep:

- Pumps, fans, and blowers – simple trip logic on vibration or overall level with 4–20 mA trending.

- Gearboxes and mixers – alarm/trip contacts into MCC logic and buffered outputs for diagnostics.

- Compressors and small turbines – compact protection when a full rack is overkill.

- Utilities & process skids – straightforward DCS integration using analog outputs and relays.

A reliability tech told me recently, “We matched the 167699‑02 build, wired the probe and 4–20s, and the monitor went green on the first run.” That’s been my experience too when the sensor type and scale factors are aligned ahead of time.

Advantages & Value

- Reliability – 24/7 protection with clear alarm status and predictable trip behavior.

- Compatibility – Analog outputs and relays drop neatly into existing DCS/PLC schemes.

- Cost control – Focused protection without the complexity of a full multi‑slot system.

- Serviceability – Labeled terminals and buffered signals (where provided) make diagnostics faster.

- Delivery assurance – Practical lead times and variant matching help you hit outage windows.

Installation & Maintenance

- Sensors: Use approved proximity probes/accelerometers; verify polarity, gaps, and scale factors before startup.

- Wiring & EMC: Route low‑level sensor cables away from VFD motor leads; maintain 360° shield bonds at the cabinet entry.

- Setpoints: Configure alert/trip per site standards; validate trips with a controlled bump or simulated input.

- Analog outputs: Check 4–20 mA scaling at the DCS/PLC; document ranges on the panel door.

- Routine care: Periodic terminal re‑torque, dust cleaning, and a quick review of alarm logs and trend stability.

- Spares: Keeping one variant‑matched module per area is, in most cases, the fastest route to recovery.

Quality & Certifications

- Produced to Bently Nevada quality systems, typically aligned with ISO 9001.

- CE/UL/cUL applicability depends on exact variant and year; we can verify by part/serial.

- RoHS status variant‑dependent; confirmation available on request.

- Warranty: 365 days repair/replace coverage from delivery.

Reviews

There are no reviews yet.