Description

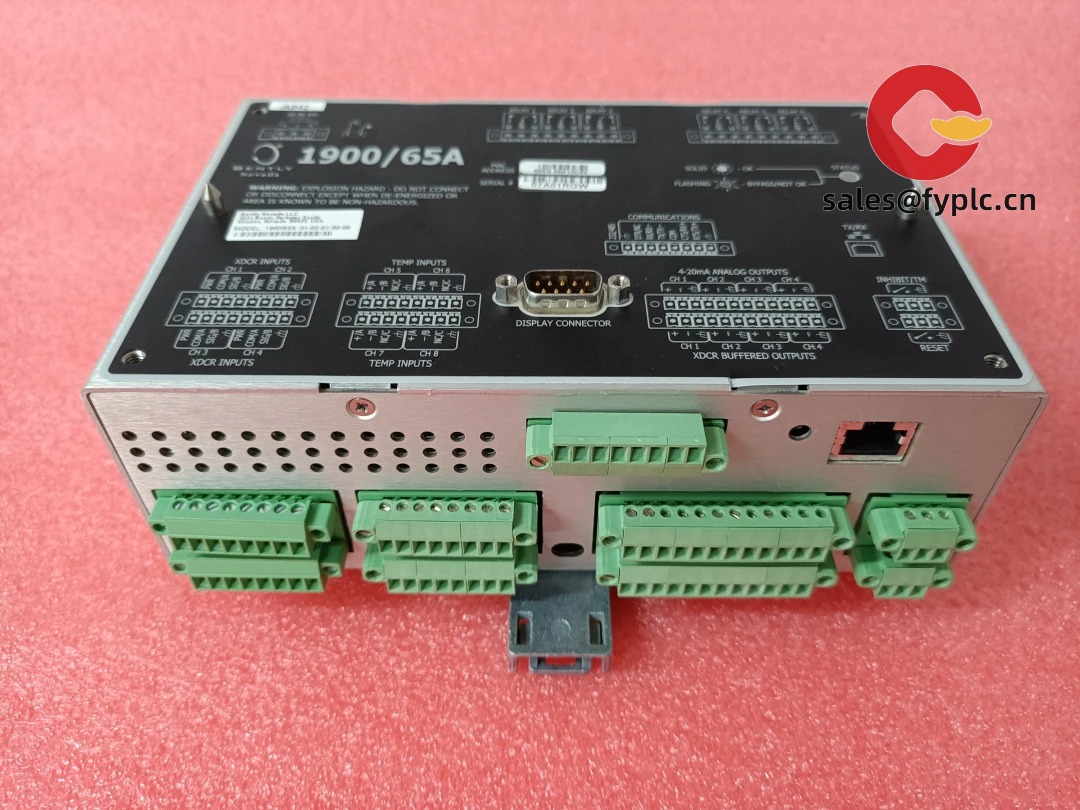

Bently Nevada 1900/65A-01-02-01-00-00 – General-Purpose Machinery Protection Monitor for Pumps, Fans, and Small Compressors

This unit is the Bently Nevada 1900/65A, a compact, DIN‑rail machinery protection monitor that helps you safeguard rotating assets with simple, reliable trip logic and easy 4–20 mA feedback to your control system. From my experience, it’s a solid fit for single or dual-bearing machines where you want proven vibration protection without the complexity of a full rack. The “-01-02-01-00-00” build typically indicates a 24 Vdc supply with dual dynamic inputs, 4–20 mA outputs, and programmable relays — a very common field configuration for pumps and blowers.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance; full payment before delivery

- Express delivery: FedEx / UPS / DHL

Key Features

- Two-channel vibration monitoring – Measures radial/axial vibration or casing acceleration/velocity for protection and trending.

- 4–20 mA per channel – Simple tie‑in to DCS/PLC; one thing I appreciate is how maintenance can trend health without extra gateways.

- Programmable alert/danger relays – Clean, deterministic trips to shut down or alarm in most cases.

- Flexible sensor support – Works with proximity probes, accelerometers, and velocity (Velomitor‑type) sensors.

- RS‑485 Modbus RTU – Lightweight integration for status, setpoints, and values; typically reduces wiring overhead.

- USB service/configuration – Faster commissioning and setpoint management on the bench or at the panel.

- DIN‑rail mounting, compact form – Saves cabinet space and simplifies retrofit projects.

- Rugged temperature range – Built for industrial environments where panels run warm.

Technical Specifications

| Brand / Model | Bently Nevada 1900/65A-01-02-01-00-00 (hardware series commonly referenced as 167699-02) |

| HS Code | 9032.89 (Other automatic regulating or controlling instruments) |

| Power Requirements | 24 Vdc nominal (typically 18–36 Vdc), <10 W typical load |

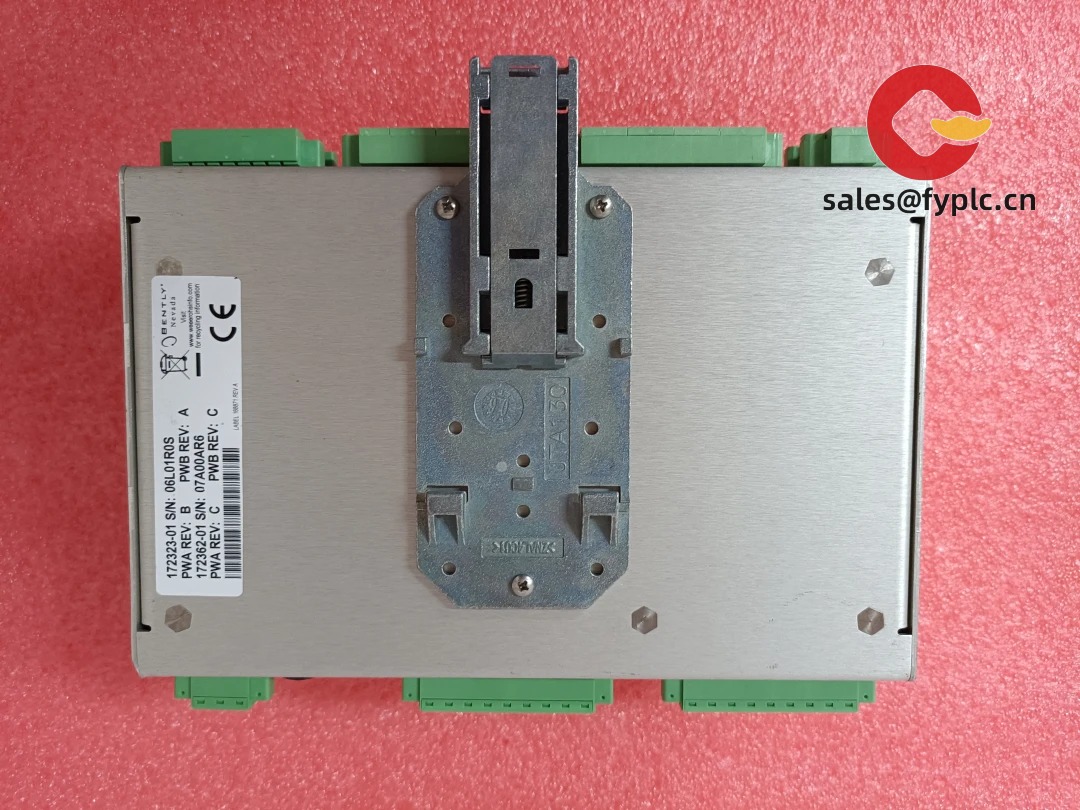

| Dimensions & Weight | Compact DIN‑rail module; approx. 100–120 mm (W) × 140–160 mm (H) × 90–120 mm (D); ~0.9–1.1 kg |

| Operating Temperature | Typically −35 °C to +70 °C |

| Signal Input Types | 2 dynamic inputs for proximity/acceleration/velocity sensors; optional tachometer (Keyphasor‑style) speed reference |

| Outputs | 4–20 mA per channel; programmable Alert/Danger relays; buffered transducer outputs available |

| Communication Interfaces | RS‑485 Modbus RTU; USB service/configuration port |

| Installation Method | DIN‑rail or panel mounting; typically used in general‑purpose or Div 2/Zone 2 panels |

Application Fields

Engineers choose the 1900/65A when they need dependable protection for:

- Process pumps and seal‑less magnetic drive pumps (API/ISO service)

- Fans, blowers, small/medium motors and gearboxes

- Vacuum pumps, compressors, centrifuges, and mixers

- Utility assets: cooling towers, HVAC drives, booster sets

- Skid OEM packages where space and simplicity matter

One maintenance lead told us they swapped older relays for a 1900/65A on a pump train and immediately got cleaner trip logic and clearer 4–20 mA trends into the PLC — fewer nuisance trips, better decisions.

Advantages & Value

- Reliability – Mature platform with predictable alert/danger behavior; in many cases this reduces unplanned stops.

- Compatibility – Works with common Bently Nevada proximity systems and industrial accelerometers/velocities; easy 4–20 mA to any PLC/DCS.

- Cost Efficiency – Lower footprint and wiring than rack systems; typically faster commissioning.

- Lifecycle Support – Straightforward field replacement, spares, and configuration backup ease long‑term ownership.

Installation & Maintenance

- Panel/Cabinet – Mount on 35 mm DIN‑rail inside a clean, ventilated enclosure; leave at least 50 mm clearance for wiring and heat dissipation.

- Power & Ground – Use a clean 24 Vdc supply; bond shield drains at the monitor end; maintain a single‑point ground to minimize noise.

- Wiring – Use shielded, twisted pairs for dynamic signals; route sensor cables away from VFD power to avoid coupling.

- Safety – Verify relay logic and fail‑safe wiring during FAT/SAT; use trip‑multiply or inhibit during run‑up/overspeed checks when applicable.

- Routine Care – Periodic visual check of terminations, confirm 4–20 mA scaling in the DCS, and re‑validate setpoints after major maintenance.

- Firmware/Config – Back up configuration files; update firmware via the service port when released by the manufacturer.

Quality & Certifications

- Certifications: CE, UL/cUL (Class I, Div 2) and ATEX/IECEx Zone 2 for many builds; RoHS compliant.

- Manufacturer Warranty: Bently Nevada provides standard warranty on new units (typically 1 year, region dependent).

- Our Coverage: 365‑day warranty on supplied units as stated above.

Supporting Components (Common Pairings)

- Bently Nevada 3300 XL Proximity Probe Systems (5 mm / 8 mm) with matching Proximitor drivers – for shaft vibration and position.

- Bently Nevada Velomitor velocity sensors (e.g., 330400 series) – for casing velocity on pumps and fans.

- Industrial IEPE accelerometers (BNC or terminal connection) – for broadband acceleration on gearboxes and motors.

- Keyphasor‑style tachometer pickups – when speed reference or phase is required for certain measurements.

- Shielded signal cable assemblies and USB configuration cable – for low‑noise installations and quick setup.

You might notice that this build code is a practical, field‑proven combination. If your application calls for different relays or comms, the 1900/65A family supports multiple option sets, so we can match it to your standards with minimal change on the panel.

Reviews

There are no reviews yet.