Description

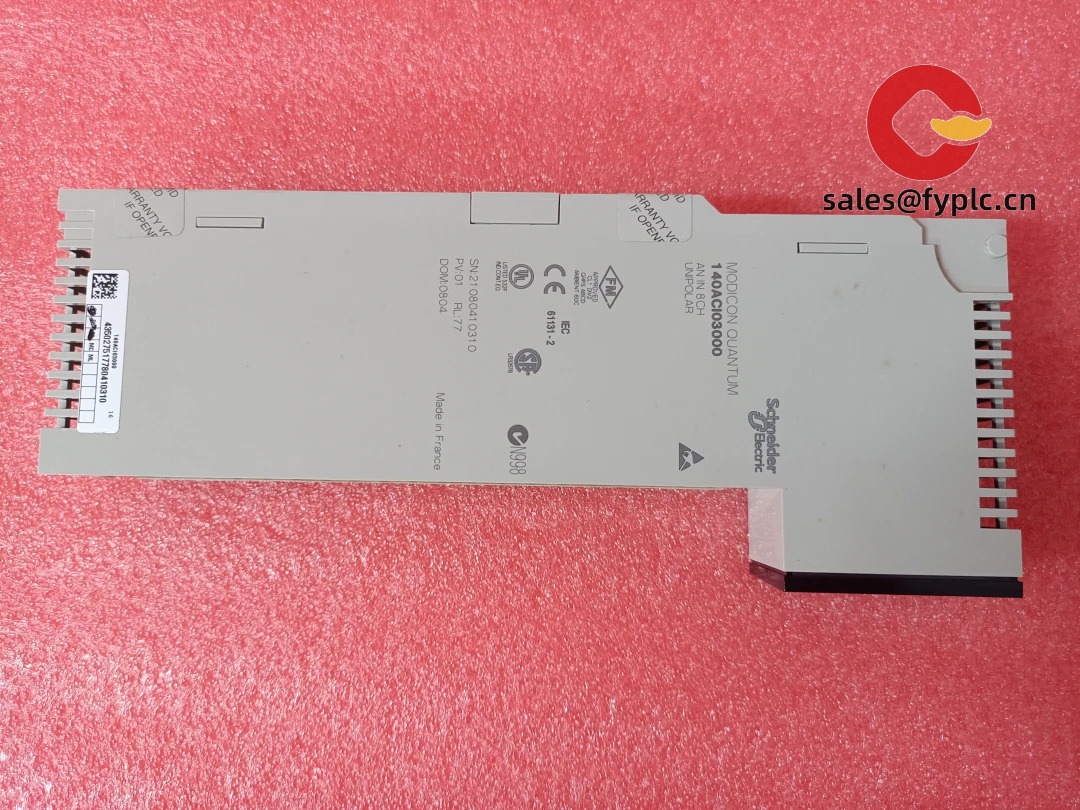

SCHNEIDER Modicon Quantum 140ACI03000 – Analog Current Input Module for 4–20 mA Signal Acquisition

The SCHNEIDER 140ACI03000 is an analog current input module for the Modicon Quantum platform, built to bring stable, noise‑resistant 4–20 mA and 0–20 mA signal acquisition into your controller. From my experience, it’s a solid fit when you’re tying in transmitters for pressure, flow, or level and you want dependable data without constant re-tuning. One thing I appreciate is how cleanly it drops into a Quantum rack and just works with existing projects—less fuss for commissioning and fewer surprises during maintenance.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- 8-channel current input – Suitable for multi-loop 4–20 mA/0–20 mA acquisition on a single module, which typically reduces rack space and cost per point.

- Industry-standard ranges – Handles 4–20 mA and 0–20 mA signals used by most industrial transmitters and positioners.

- Stable readings in noisy panels – Designed for industrial environments; you might notice fewer spikes when drives or large motors are nearby.

- Diagnostics for over/under-range – Helps pinpoint loop issues faster, especially when a transmitter loses power or a wire is open.

- Backplane integration – Seamless connection to the Quantum I/O bus for low-latency updates and straightforward configuration in common Schneider toolchains.

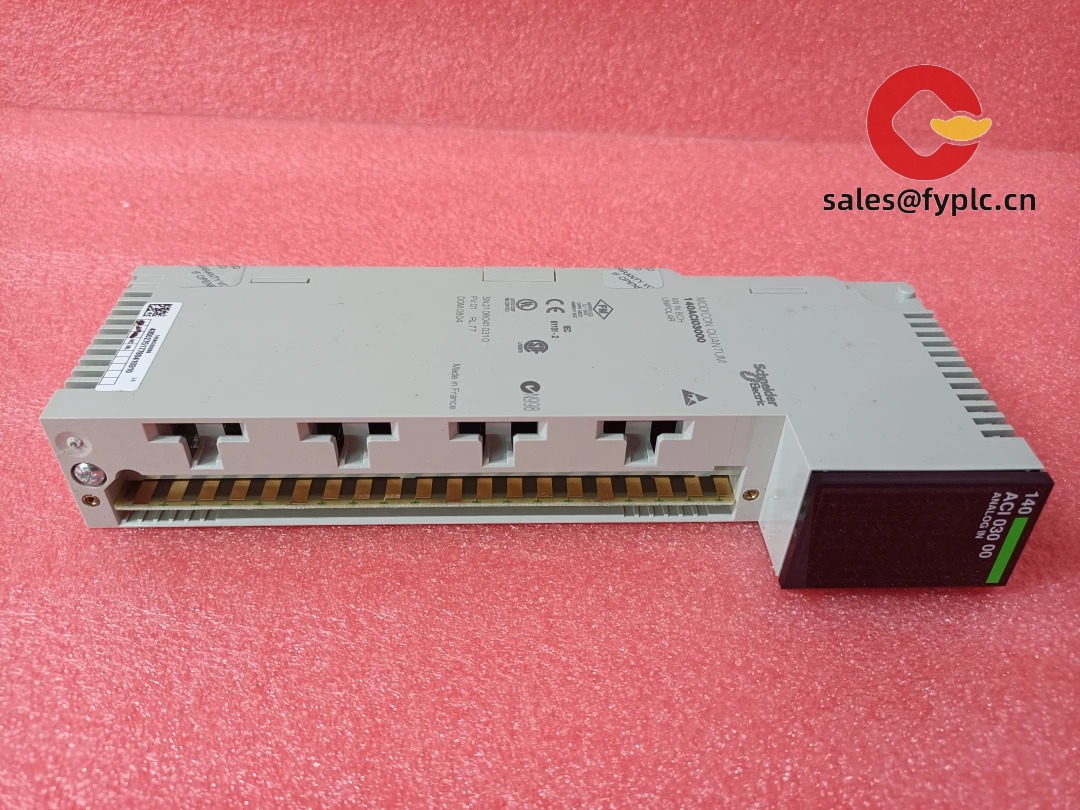

- Removable front connector – Makes wiring and module swap-outs quicker during planned shutdowns.

Technical Specifications

| Brand / Model | Schneider Electric Modicon Quantum / 140ACI03000 |

| Product Type | Analog Current Input Module (PLC I/O) |

| HS Code | 8538.90 (Parts for switching/controlling apparatus) |

| Channels | 8 analog inputs (current) |

| Signal Input Types | 4–20 mA, 0–20 mA (typical industrial ranges) |

| Communication Interfaces | Modicon Quantum backplane I/O bus (local rack) |

| Power Requirements | Powered via Quantum backplane (5 VDC supplied by rack power supply) |

| Operating Temperature | 0 to 60 °C (32 to 140 °F), typical for Quantum modules |

| Installation Method | Single-slot module, installs in Modicon Quantum rack (e.g., 140XBP series) |

| Dimensions & Weight | Standard Quantum single-slot form factor; suitable for panel-mounted racks |

Application Fields

Typical deployments include process and utilities where 4–20 mA remains the default: water & wastewater (level, flow), oil & gas skids (pressure, temperature transmitters), chemicals (density, pH via transmitter), power plants (steam loop instrumentation), and large HVAC systems (differential pressure, valve positioners). You might notice the 140ACI03000 is especially handy in brownfield upgrades—reusing existing loops while modernizing the control platform.

Advantages & Value

- Reliability – Quantum I/O has a long track record in harsh plants; downtime due to module faults is rare in most cases.

- Compatibility – Works with existing Quantum racks, power supplies, and CPUs, minimizing retrofit complexity and engineering hours.

- Cost efficiency – 8 channels per module keeps cost per point competitive, especially when panel space is tight.

- Lifecycle support – Documentation, spare parts availability, and a large user base make maintenance straightforward.

Installation & Maintenance

- Panel & cabinet – Mount the Quantum rack on a grounded metal panel within a sealed cabinet. Allow ventilation above/below the rack; keep ambient within 0–60 °C.

- Wiring – Use shielded twisted pairs for 4–20 mA loops. Tie shields to a single-point ground to avoid ground loops. Keep analog cables separated from VFD or high-voltage runs.

- Loop power – For 2-wire transmitters, verify loop supply and polarity. It appears that under-range diagnostics catch open-loop conditions in many cases, but a quick current check with a meter saves time.

- Commissioning – Scale engineering units in the PLC software and validate with a portable calibrator at two or three points (e.g., 4 mA, 12 mA, 20 mA).

- Maintenance – Periodically inspect terminal tightness, clean dust from the module face, and review firmware or configuration backups. Annual loop checks typically keep drift in check.

- Safety – De-energize the rack before inserting/removing the module. Follow lockout/tagout procedures and verify cabinet bonding.

Quality & Certifications

- Certifications: CE, UL, CSA (RoHS compliance may vary by production batch)

- Manufacturer: Schneider Electric, Modicon Quantum series

- Warranty: 12 months (365 days)

Quick customer note: a wastewater client swapped three legacy current cards for 140ACI03000 modules during a weekend shutdown—rewired the loops to the removable connector, restored the project, and had clean trends by Monday. The main win, as they put it, was “no surprises on start-up and stable readings next to two big blowers.”

Reviews

There are no reviews yet.