Description

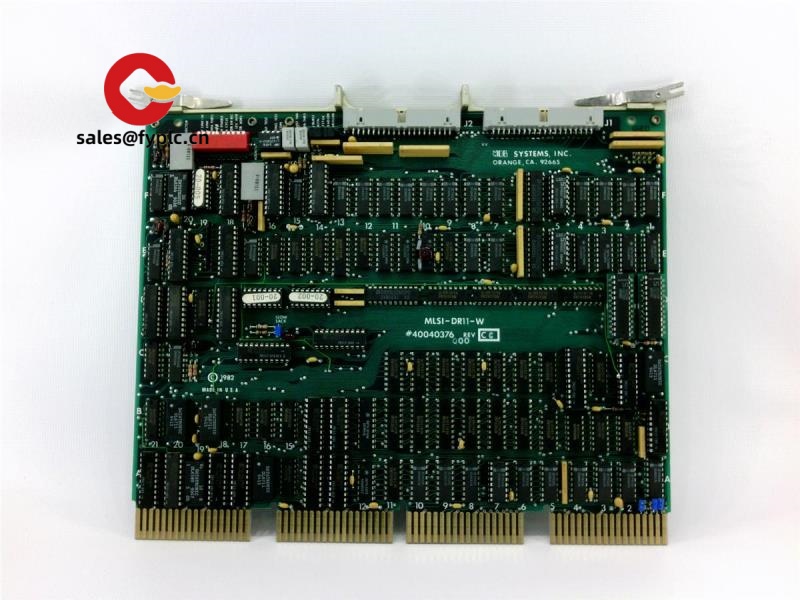

MDB MLSI-DR11-W – DIN-rail digital I/O relay interface for machine panels and OEM control

The MDB MLSI-DR11-W is a compact, DIN-rail industrial I/O interface that, in most cases, combines 24 VDC digital signals with relay output channels for direct control of field devices. From my experience, it’s typically used to bridge PLC logic with on-panel actuators—contactors, valves, beacons—while keeping wiring tidy and isolating noisy loads from your controller. If you’re building small to mid-size cabinets, this kind of module helps streamline terminal counts and reduce custom relay boards.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express delivery options: FedEx, UPS, DHL

Key Features

- DIN-rail, slim form factor – Fits standard 35 mm rails, helping keep panels compact and service-friendly.

- Digital I/O with relay outputs – Typically supports 24 VDC logic with isolated relay contacts to switch small loads without extra relay base hardware.

- Electrical isolation – Input-to-output isolation reduces noise coupling; helpful in drives, solenoids, and mixed-signal cabinets.

- Clear wiring layout – Labeled terminals and front-access connectors make commissioning faster; you might notice fewer wiring errors on site.

- Panel-ready power – Runs on 24 VDC in most cases, so it drops into standard control circuits.

- Status indication – Channel LEDs (where provided) speed up troubleshooting and FAT/SAT checks.

Technical Specifications

| Brand / Model | MDB / MLSI-DR11-W |

| HS Code | 8537.10 (Boards/panels for electric control; typical classification for industrial control assemblies) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC), internal consumption low; size your supply with 20–30% headroom |

| Dimensions & Weight | Approx. 120 × 25 × 75 mm; ~0.15 kg (varies slightly by sub-revision) |

| Operating Temperature | -10 to +55 °C; 5–95% RH, non-condensing (typical for this class) |

| Signal Input/Output Types | Digital 24 VDC inputs with opto-isolation and relay outputs (SPST/SPDT) for low-voltage load switching; exact channel count depends on variant |

| Communication Interfaces | Dry-contact I/O; some deployments pair with PLC digital cards or RS-485/Modbus gateways for monitoring status |

| Installation Method | 35 mm DIN-rail (EN 60715), front-wired screw or push-in terminals; IP20 indoor panel use |

Application Fields

You’ll usually find the MLSI-DR11-W in OEM machinery panels, packaging lines, simple process skids, building services (fan/valve control), water treatment kiosks, and conveyor control boxes. One thing I appreciate is how it simplifies retrofits—drop it next to an existing PLC, map your digital points, and you’ve got clean relay switching without redesigning the whole cabinet.

- Machine builders: interlocking, beacon stacks, door switches, and small solenoids

- Utilities & water: pump run feedback, local override relays, alarm fan-outs

- Facilities & BMS: damper/valve actuation, status aggregation to the main controller

- Material handling: diverter gates, sensor banks, e-stop loop segmentation

Advantages & Value

- Reliable switching – Isolated relay contacts reduce PLC card stress and help with noisy inductive loads.

- Compatibility – Works with most 24 VDC PLC digital I/O; wiring conventions are straightforward for technicians.

- Cost-effective – In many cases it replaces multiple relay sockets and interposing wiring, cutting assembly time.

- Serviceability – Front indicators and labeled terminals speed fault finding during commissioning and audits.

Installation & Maintenance

- Panel environment: mount on 35 mm DIN-rail inside an enclosure; allow ventilation space (typically ≥20 mm top/bottom).

- Power & grounding: use a regulated 24 VDC supply; common the 0V reference; ground the rail and segregate high-voltage wiring.

- Wiring: use ferrules; separate signal and power paths; add RC snubbers or flyback diodes on inductive loads to extend relay life.

- Safety: de-energize before servicing; verify isolation when switching mixed AC/DC loads; follow local electrical codes.

- Routine checks: quarterly tighten terminals, clean dust, verify indicator LEDs, and function-test critical relays.

Quality & Certifications

- Compliance: typically CE and RoHS for control panel components; UL/CSA panel use depends on panel listing practice

- Manufacturer’s warranty: 12 months (365 days) from shipment

Complementary Components (often ordered together)

- 24 VDC industrial power supply (with ≥20% spare capacity)

- DIN-rail end clamps and labeled terminal markers for clean routing

- RC snubbers or TVS diodes for inductive loads to protect relay contacts

- Shielded field cables and ferrules to reduce noise and speed installation

- Optional RS-485/Modbus gateway if remote status monitoring is required

Reviews

There are no reviews yet.