Description

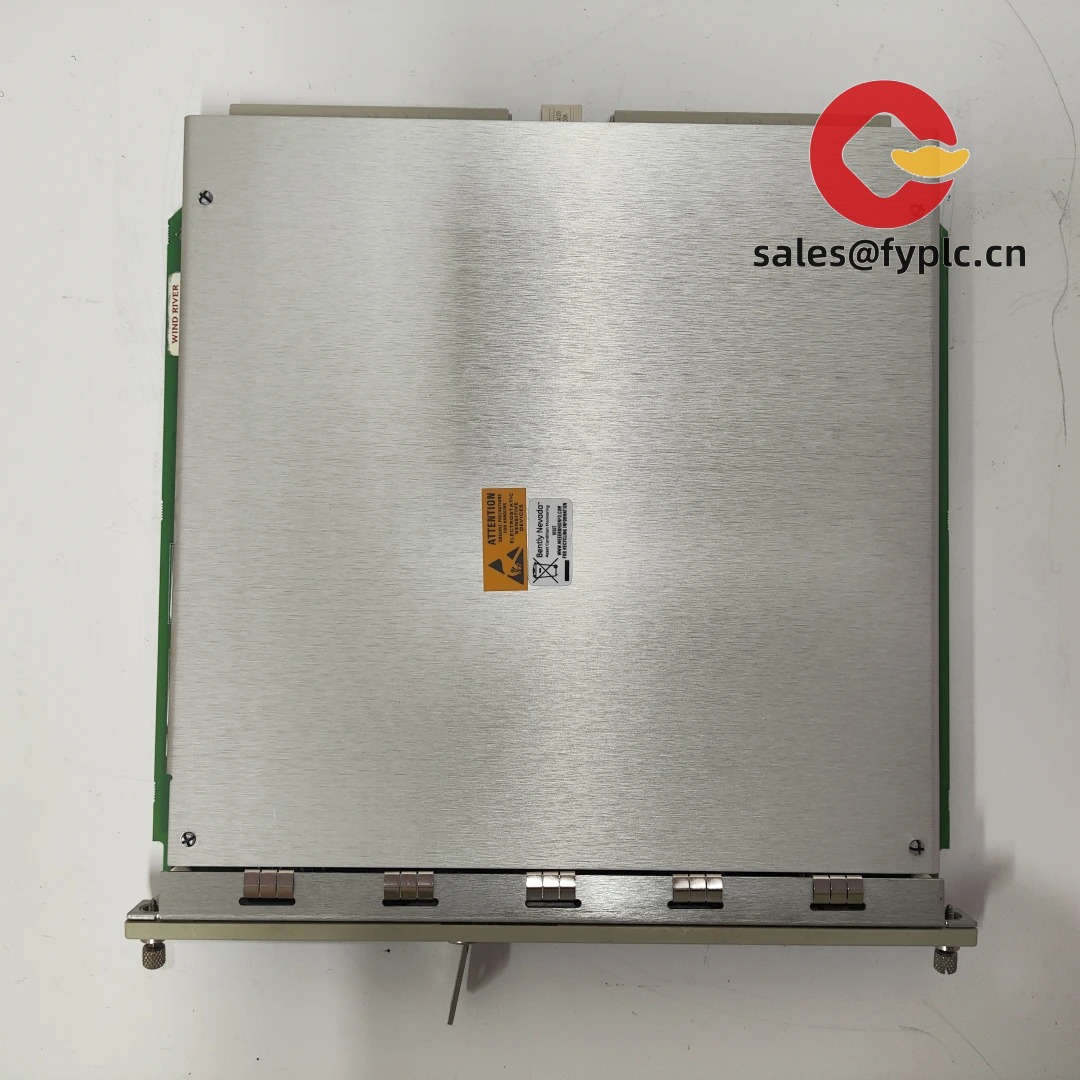

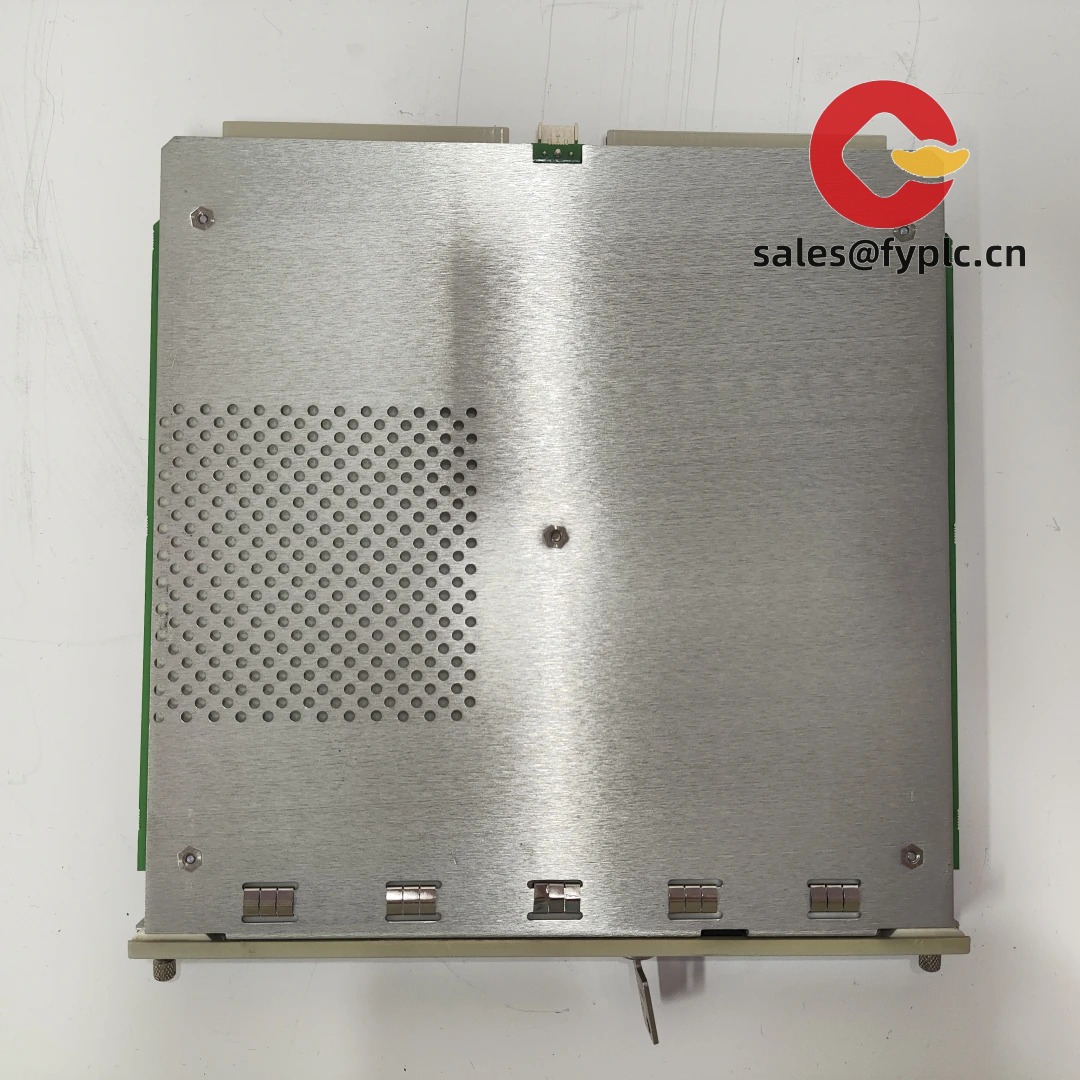

Bentley Nevada 3500-22M (138607-01) – Transient Data Interface for 3500 Machinery Protection Racks

The Bentley Nevada 3500-22M Transient Data Interface (TDI) is the communications and data acquisition backbone for a 3500 rack. From my experience, it’s the piece that makes your machinery protection system “visible” to the plant network—collecting static, dynamic, and transient waveform data from all installed 3500 monitor cards and serving it securely over Ethernet. Part number 138607-01 typically denotes a standard 22M hardware assembly variant used widely in oil & gas, power generation, and heavy process industries.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Centralized rack data interface: Aggregates status, alarms, static values, and transient waveforms from all installed 3500 monitors.

- Ethernet connectivity: Provides a single network access point to the rack for configuration and condition monitoring software.

- Transient/fault capture: Typically captures pre/post-event vibration and process data to speed up root-cause analysis after trips.

- Rack-wide synchronization: Uses the 3500 backplane to coordinate data with monitor modules; time sync commonly via plant network.

- Designed for demanding sites: Industrial form factor suited for continuous operation in machinery protection cabinets.

- Minimal wiring changes: No direct sensor wiring to the TDI—data flows via the 3500 backplane, which makes upgrades cleaner.

Technical Specifications

| Brand / Model | Bentley Nevada 3500-22M (P/N 138607-01) |

| HS Code | 9031.80.00 (Measuring/monitoring instruments – other) |

| Power Requirements | Powered via 3500 rack backplane; no external power supply |

| Communication Interfaces | Ethernet (10/100 Mbps, RJ‑45) for configuration and condition monitoring software |

| Signal I/O Types | No direct transducer inputs; interfaces digitally with 3500 monitor modules over the rack backplane |

| Operating Temperature | Typically 0 to +65°C for 3500 modules (application dependent) |

| Dimensions & Weight | 3500 rack plug-in module form factor; single-width style used in standard 3500 racks |

| Installation Method | Installs in the designated TDI slot of the 3500 rack; connects through the backplane |

Application Fields

You’ll typically see the 3500-22M in continuous machinery protection cabinets where online condition monitoring is required:

- Oil & Gas: large compressors, gas turbines, pumps on upstream and midstream assets

- Power Generation: steam/gas turbines, generators, critical balance-of-plant machines

- Petrochemical & Refining: high-speed rotating equipment on continuous processing lines

- Pulp & Paper, Mining, and Steel: fans, blowers, mills where transient capture is valuable after trips

Advantages & Value

- Proven reliability: The TDI has become the standard interface in many 3500 deployments due to its stable operation and low maintenance burden.

- Seamless compatibility: Works natively with the 3500 rack and monitor modules; no extra converters for routine configuration and data access.

- Lower total cost of ownership: A single Ethernet point reduces cabinet wiring, network ports, and engineering hours.

- Diagnostic depth: Transient capture seems to be the biggest time-saver after process upsets—faster fault isolation, fewer blind spots.

- Lifecycle support: Typically supported across 3500 system generations, which helps with spares planning and fleet standardization.

Installation & Maintenance

- Cabinet & environment: Install in a clean, ventilated control cabinet with adequate airflow; avoid persistent condensation and corrosive atmospheres.

- Wiring & grounding: Use shielded Ethernet within the cabinet when practical; maintain a single-point ground strategy and route network cables away from high-noise conductors.

- Rack position: Fit the 3500-22M in the designated TDI slot (typically near the power supply) as specified by the rack layout.

- Network setup: Assign fixed IPs within the control VLAN; many plants use NTP to keep event timestamps aligned across systems.

- Safety precautions: De-energize the rack before inserting/removing modules; observe ESD handling to protect backplane connectors.

- Routine care: Periodically back up configuration, review event/alarm logs, clean dust from the cabinet filters, and apply firmware updates during planned outages.

Quality & Certifications

- CE marked for EMC and safety

- UL/cUL and CSA certifications are commonly available for 3500 system modules

- Manufacturer warranty practice is typically 12 months; we support a 365‑day warranty on supply

- RoHS conformity where applicable to the production batch

Compatible & Supporting Components

You might notice the 3500-22M delivers the best value when paired with the right rack and modules. Typical companions include the 3500/15 Power Supply, 3500/05 Rack, and monitor cards (e.g., 3500/40M, 3500/42M) for vibration and speed. Many users also maintain a spare TDI to reduce MTTR—small investment, big uptime payoff in many cases.

A recent customer in a gas compression facility mentioned that switching to the 22M significantly improved post-trip investigations because transient data capture lined up perfectly with their DCS events—what used to take days now took a couple of hours.

Reviews

There are no reviews yet.