Description

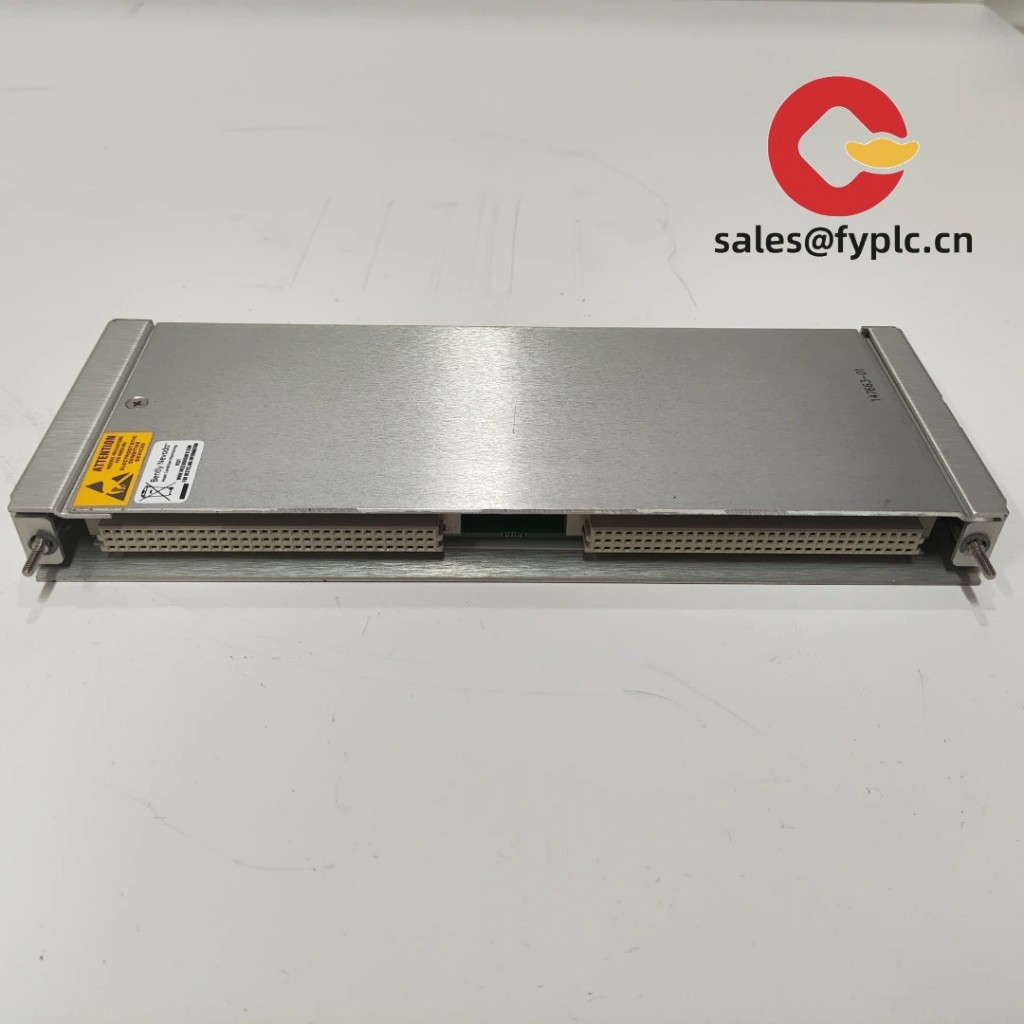

Bently Nevada 3500/92 (136188-01) – Communications Gateway for DCS/PLC Modbus Integration

The Bently Nevada 3500/92 Communications Gateway pulls together measurement values, OK status, Alert/Danger conditions, relay states, and rack health from the entire 3500 system and publishes them to your control system via Modbus. From my experience, the 136188-01 hardware variant is a safe choice when you want a stable, read‑only bridge into DCS/PLC without relying on third‑party protocol converters. It keeps the protection architecture clean: TDI handles configuration and waveform data, while the 3500/92 focuses on deterministic Modbus.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment, full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Rack-wide data access: Publishes channel values, Alert/Danger, Not OK, relay states, and rack health from all installed monitors.

- Modbus for controls: Supports Modbus TCP over Ethernet and Modbus RTU over RS‑485, which covers most DCS/PLC needs.

- Read‑only interface: Keeps protection logic insulated from control-layer writes—safer for trip paths and audits.

- Tight 3500 integration: Pulls data via the backplane; no extra sensors or external protocol boxes to maintain.

- Commissioning friendly: Predictable register maps and clear front-panel status LEDs make FAT/SAT point checks quick.

Technical Specifications

| Brand / Model | Bently Nevada 3500/92 Communications Gateway (P/N 136188-01) |

| HS Code | 9031.80.00 (Measuring/monitoring instruments – other) |

| Power Requirements | Powered via 3500 rack backplane; no external power supply |

| Communication Interfaces | Ethernet 10/100Base‑T (Modbus TCP); RS‑485 (Modbus RTU) |

| Signal Input/Output Types | Digital data from the 3500 backplane; outputs as Modbus registers and status bits; no direct transducer inputs |

| Operating Temperature | Typically 0 to +65 °C for 3500 modules (installation dependent) |

| Dimensions & Weight | Standard 3500 single‑width front module with rear I/O terminal base |

| Installation Method | Plugs into the 3500 rack; configuration performed via 3500‑22M TDI and engineering software |

Application Fields

You’ll typically deploy the 3500/92 anywhere you need clean, consistent protection data in the control layer:

- Oil & Gas: mapping vibration/position alarms and OK/Danger status to DCS and ESD inputs

- Power Generation: feeding key 3500 values and health into plant control networks for annunciation

- Refining & Petrochemicals: standardizing Modbus tag structures across units for uniform HMIs

Advantages & Value

- Reliable integration path: Native gateway avoids third‑party protocol boxes and reduces interface risk.

- Compatibility out of the box: In many cases the Modbus map aligns with common DCS/PLC templates, cutting engineering time.

- Operational safety: Read‑only design prevents inadvertent writes into protection logic.

- Lower lifecycle cost: Fewer devices to manage, simpler spares, and straightforward FAT/SAT testing.

Installation & Maintenance

- Cabinet & environment: Install the 3500 rack in a clean, ventilated enclosure; avoid condensation and corrosive atmospheres.

- Networking: Use a controls VLAN and fixed IPs for Modbus TCP; for RS‑485, maintain proper termination, biasing, and shielding.

- Commissioning steps: Verify OK, Alert, Danger, relay states, and rack health points against the Modbus register list—most teams script a quick DCS poll to confirm.

- Safety & handling: De‑energize the rack before inserting/removing modules; observe ESD precautions to protect backplane connectors.

- Routine care: Back up the rack configuration, review event logs after trips, and plan firmware updates during scheduled outages.

Quality & Certifications

- CE marked for EMC and safety (3500 family)

- UL/cUL and CSA certifications commonly available for 3500 modules

- RoHS conformity where applicable

- Manufacturer’s warranty is typically 12 months; we support a 365‑day warranty on supply

Practical Pairing & Field Note

One thing I appreciate is the simple split: 3500‑22M TDI for configuration and waveform diagnostics, and 3500/92 purely for Modbus into the DCS. In most cases that separation keeps cybersecurity reviews and late‑stage commissioning a lot calmer.

A controls engineer at a midstream site mentioned their switch to the 3500/92 cut “bad quality” alarms during startups. “Once our DCS tags matched the rack’s map, operators stopped second‑guessing the panel,” was the feedback. It seems to be a common result when you keep the gateway native.

Reviews

There are no reviews yet.