Description

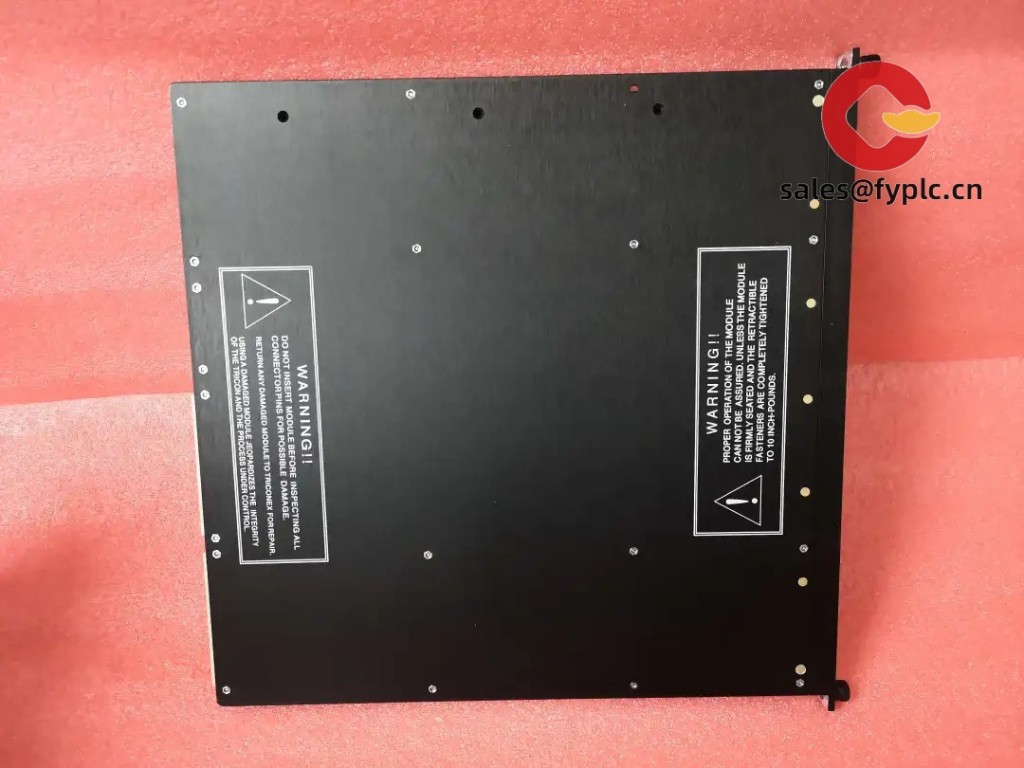

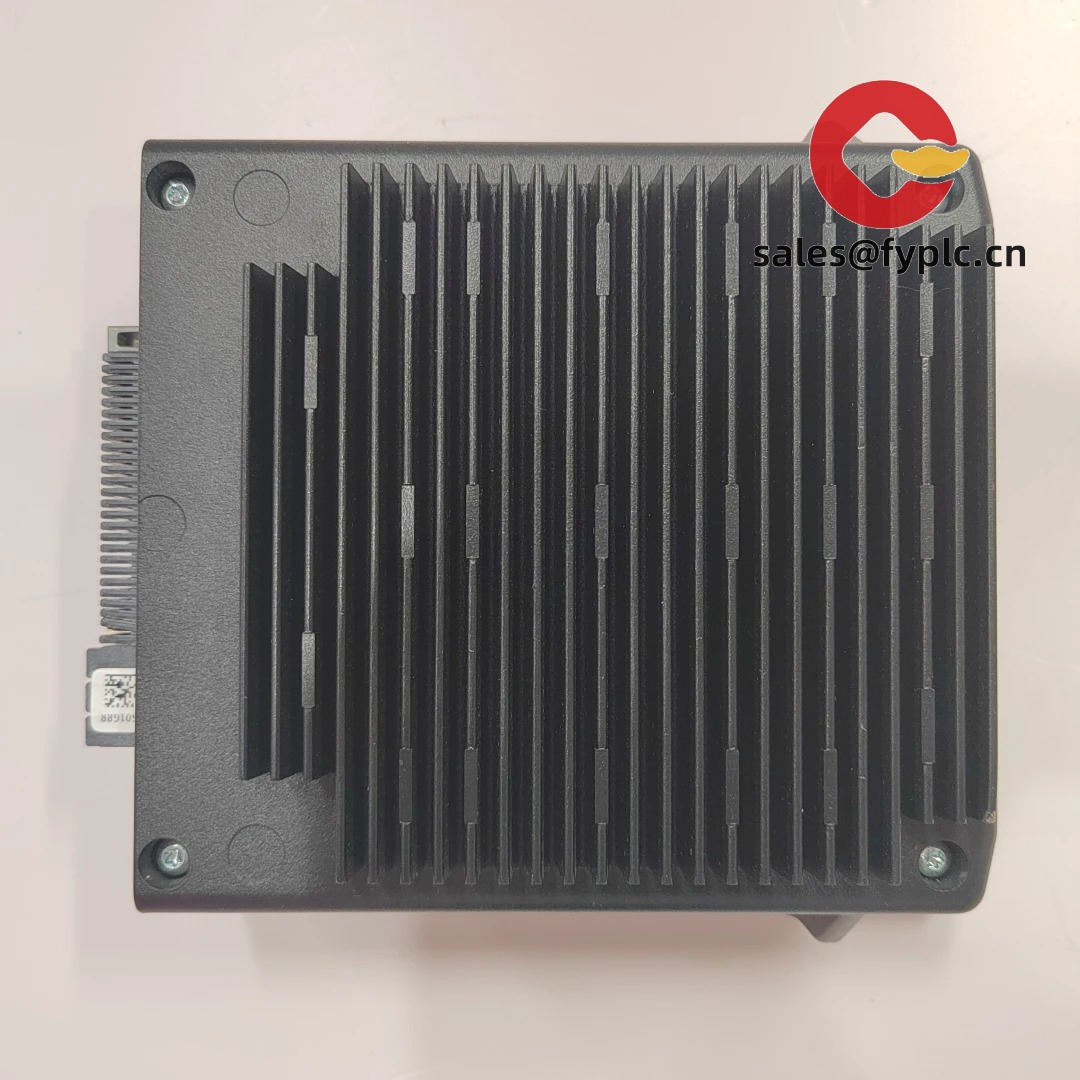

Bently Nevada 3701/55 Machinery Protection Module – Trusted trip and condition monitoring for critical rotating assets

The 3701/55 sits within Bently Nevada’s 3701 series and is used in high‑integrity machinery protection racks where you need dependable alarm/trip logic tied to real vibration and speed measurements. From my experience, it’s typically selected on turbines, compressors, and high‑value pumps when a plant wants proven protection hardware with straightforward field wiring and clean diagnostics. You might notice people sometimes write “Bentley” in listings; the brand is Bently Nevada (part of Baker Hughes).

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment prior to delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Purpose‑built machinery protection

– Designed for real‑time alarm and trip functions on rotating equipment where downtime is costly. - Works with proven Bently Nevada transducers

– Typically supports proximity probes, seismic/accelerometers, and speed pick‑ups via the proper terminal base and rack. - Discrete relay alarming/trip

– Dry‑contact outputs for driving shutdown circuits, interposing relays, and permissives in many cases. - Buffered transducer signals

– Convenient for portable diagnostics and route data capture without disturbing the process. - Rack‑based architecture

– Hot‑swappable module concept with front status LEDs and clear channel health indications. - Plantwide integration options

– When used with the appropriate communication/processor cards, it interfaces with condition monitoring software for trending and event capture. - Lifecycle‑friendly design

– Spare strategy and migration paths are straightforward for plants standardized on Bently Nevada hardware.

Technical Specifications

| Brand / Model | Bently Nevada 3701/55 (Machinery Protection Module) |

|---|---|

| HS Code | 903289 (Automatic regulating/controlling instruments, other) |

| Power Requirements | Supplied by the 3701 rack power supply; 24 VDC nominal in most installations (refer to rack manual for current draw) |

| Operating Temperature | Typically 0 to +65 °C, non‑condensing environment |

| Signal Input/Output Types | Sensor inputs via associated terminal base (e.g., proximity probes, seismic, speed pick‑ups); discrete relay outputs for alarm/trip; buffered transducer outputs available |

| Communication Interfaces | Proprietary backplane to the 3701 system; configuration and data access via the system processor/engineering port (as applicable) |

| Installation Method | Plug‑in rack module; front‑access LEDs; hot‑swap procedures per OEM guidance |

| Dimensions & Weight | Standard 3701 rack card format; fits compatible Bently Nevada 3701 chassis slots |

Application Fields

Plants typically deploy the 3701/55 in units where a fast, deterministic trip is as important as rich condition data. Examples that come up often:

- Gas/steam turbines – speed and vibration protection with clean trip relays to ESD systems.

- Compressors (centrifugal, reciprocating) – surge‑prone or high‑load services where continuous monitoring and fast shutdown prevent damage.

- Pumps and fans – critical utility machines with permissive interlocks driven by high/low vibration levels.

- Industrial drives and gearboxes – alarm/trip logic tied to bearing or casing measurements.

Advantages & Value for Procurement

- Reliability that maintenance trusts – Stable hardware, predictable relay behavior, and clear status LEDs.

- Compatibility – Works with Bently Nevada probes and terminal bases, reducing interface risks and speeding commissioning.

- Reduced lifecycle cost – Hot‑replaceable modules and common spares across the 3701 family typically lower inventory burden.

- Data continuity – When connected to plant software, you retain trend history for root‑cause analysis after trips.

- Service and migration – Established global support network and migration paths from legacy systems.

Installation & Maintenance

- Cabinet environment – Mount the rack in a clean, dry cabinet with adequate ventilation; keep ambient within the stated temperature range.

- Wiring practices – Use shielded, properly grounded transducer cables; separate low‑level signals from power cabling; observe relay contact ratings and add snubbers across inductive loads.

- Grounding & noise – Single‑point ground the rack per OEM recommendations to minimize ground loops and EMI.

- Safety – Follow site LOTO before changing field wiring. Hot‑swap only per manufacturer procedures and after bypassing trips as required by site policy.

- Routine maintenance – Periodic proof testing of alarm/trip paths, check terminal torque, clean dust from card edges, and apply firmware updates through controlled MOC where applicable.

Quality & Certifications

- Compliance – Typically CE and RoHS; many installations also reference UL/CSA for the rack assembly.

- Functional safety – Certain 3701 system configurations support IEC 61508 SIL applications when engineered per the safety manual (verify for your exact hardware revision).

- Warranty – 365 days from delivery.

A maintenance lead from a power plant summed it up well: “The 3701 rack gives us the trips we need and the data we want—without chasing nuisance alarms.” That seems to be the sweet spot for the 3701/55 in most cases.

Reviews

There are no reviews yet.