Description

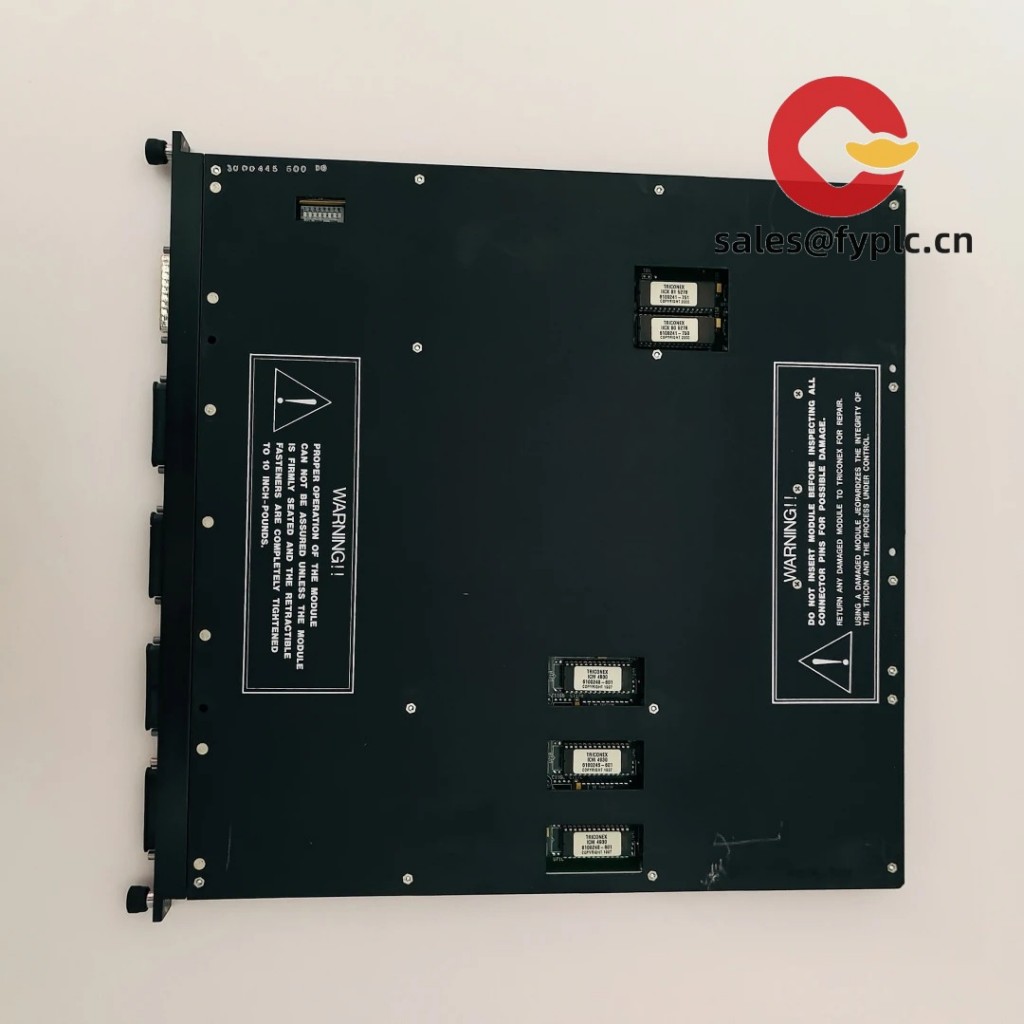

Triconex 3721C Digital Input Module – High-integrity 24 VDC discrete input for TMR safety systems

The Triconex 3721C is a trusted digital input module for Tricon TMR safety PLCs, typically used to bring back 24 VDC status signals from field devices in ESD, F&G, and BMS applications. From my experience, it’s the go‑to when you want deterministic, trip‑grade inputs with solid diagnostics and minimal fuss during turnarounds. The “C” variant is commonly supplied with conformal coating, which helps in corrosive or high‑humidity environments—useful in offshore or coastal plants.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Triple‑Modular Redundancy (TMR)

– Works within the Tricon safety platform for fault tolerance and high availability. - 24 VDC digital input channels

– Typically 32 points per module to bring back limit switches, pressure switches, contacts, and dry‑contact status signals. - Robust diagnostics

– Continuous channel health monitoring with clear front‑panel status; you spot wiring or channel issues faster. - Hot‑replaceable design

– Module changes can usually be done online in a healthy TMR configuration following OEM procedure. - Galvanic isolation

– Field‑to‑system isolation helps reduce noise coupling and improves resilience in electrically harsh areas. - Conformal‑coated variant

– The 3721C version is suited to environments where moisture or corrosive agents are a concern.

Technical Specifications

| Brand / Model | Triconex 3721C (Digital Input Module) |

|---|---|

| HS Code | 853890 (Parts for electrical control panels and programmable controllers) |

| Power Requirements | Powered via Tricon backplane (typical 5 V/24 V rails; see system manual for module current) |

| Operating Temperature | Typically 0 to +60 °C, non‑condensing environment |

| Signal Input/Output Types | 24 VDC discrete inputs (commonly 32 channels); field wiring via Triconex termination assemblies; status/diagnostic LEDs on the front panel |

| Communication Interfaces | Tricon system backplane; configured and monitored by Tricon controllers and engineering tools |

| Installation Method | Plug‑in module for Tricon main chassis; front‑access LEDs; hot‑swap capable per OEM procedure |

| Dimensions & Weight | Standard Triconex full‑height card format; fits compatible Tricon chassis slots |

Application Fields

Plants use the 3721C anywhere safe, deterministic digital inputs matter more than fancy features. Typical signals include permissives, trips, limit switches, and contact statuses:

- Emergency Shutdown (ESD) – pushbuttons, shutdown valves’ limit switches, pressure/level switch inputs.

- Fire & Gas (F&G) – detector relays, manual call points, suppression system feedback.

- Boiler/BMS and turbine protection – permissive interlocks, trips, and status contacts.

- Refining, petrochemical, LNG – field contact aggregation in SIL‑rated safety systems.

- Power generation & utilities – breaker status, interlocks, and balance‑of‑plant signals.

Advantages & Value

- Reliability that reduces nuisance trips – TMR processing and robust diagnostics help isolate faults cleanly.

- Compatibility – Native fit with Tricon controllers and termination assemblies; shortens commissioning time.

- Lower lifecycle cost – High channel density and hot‑swap capability typically cut downtime and spares variety.

- Harsh‑area resilience – The C‑suffix variant is well suited to sites with humidity or corrosive atmospheres.

- Supportable choice – Documentation and global service coverage for the Tricon platform are mature.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet within the specified temperature range; maintain front clearance for card extraction.

- Wiring – Use the designated Triconex termination assembly and cables. Keep input wiring separated from power conductors and follow grounding/shielding best practices.

- Safety – Apply LOTO before touching field wiring. For hot‑swap, follow OEM steps and bypass trips per site policy.

- Routine proof tests – Periodically validate each input path (contact operation, channel indication) per your SIL proof‑test interval.

- Configuration control – Keep controller firmware and logic under MOC; back up before planned changes.

Quality & Certifications

- Functional safety – Triconex systems are widely certified to IEC 61508 up to SIL3 when engineered per the safety manual; the 3721C is a component within that certified architecture.

- Compliance – Typically CE compliant; many projects also reference UL/CSA and RoHS for the overall system assembly.

- Warranty – 365 days from delivery.

A maintenance supervisor from a chemicals site told me, “We swapped in a 3721C during a live window—no drama, and diagnostics caught a mis‑wired limit switch before startup.” That kind of predictability is why this module keeps showing up in critical cabinets.

Reviews

There are no reviews yet.