Description

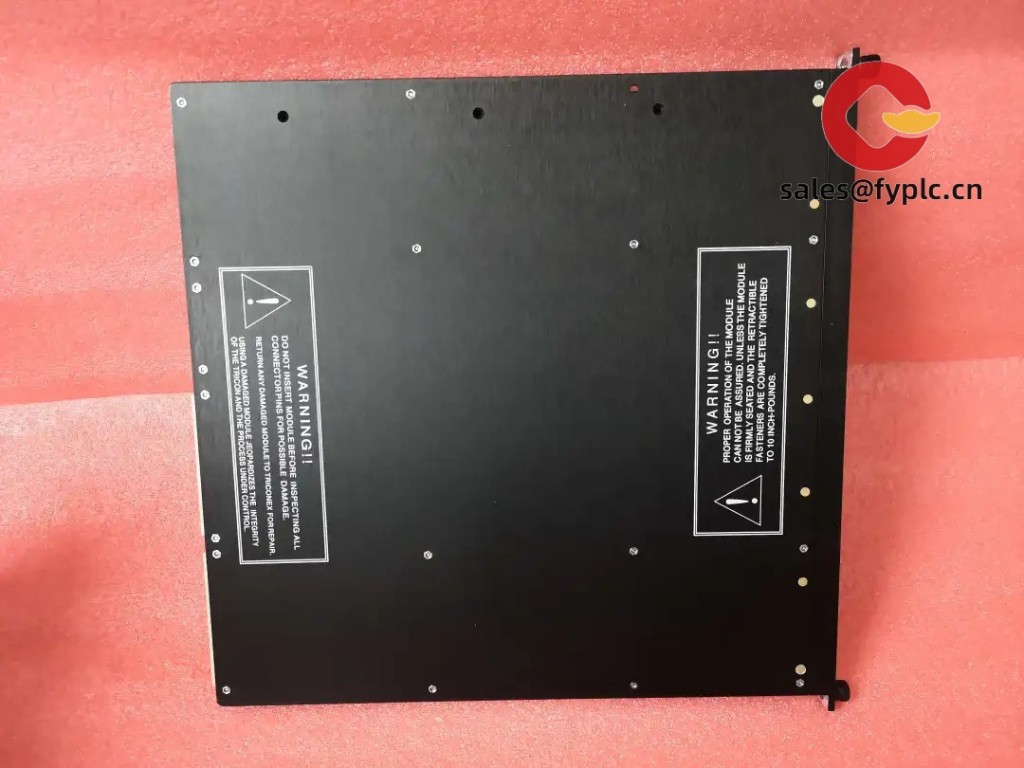

Triconex 4119A Termination Assembly – Clean, reliable field wiring interface for Tricon safety I/O

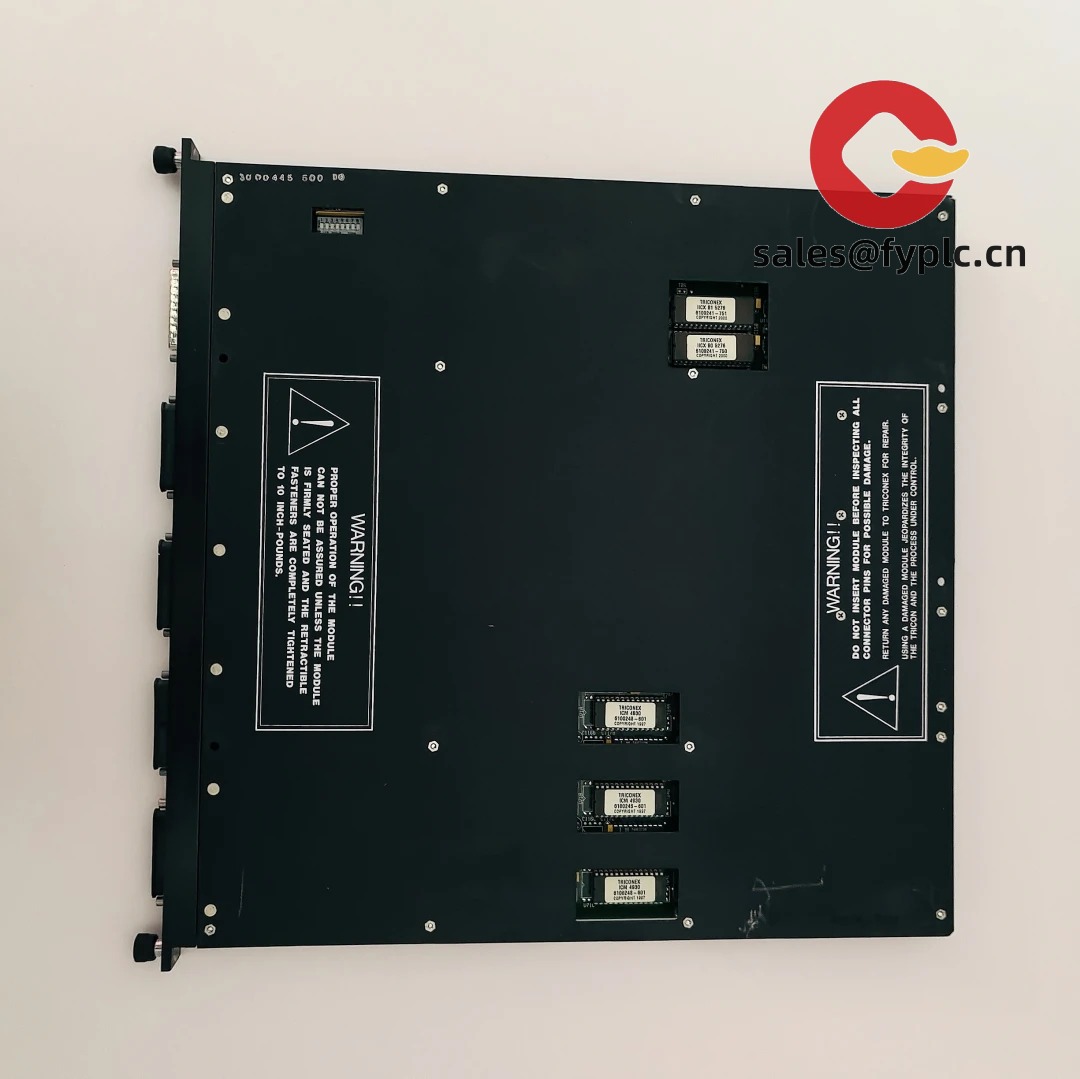

The Triconex 4119A is a termination assembly (TA) used to land field wiring and connect it neatly to the matching Tricon/Triconex I/O module via an interface cable. From my experience, it’s the quiet hero in an ESD or F&G cabinet—clear channel labeling, robust terminals, and a straightforward path from plant devices to the TMR controllers. You might notice that different projects pair this TA with different 36xx/37xx I/O cards; that’s by design, as the TA streamlines cabinet build and ongoing maintenance.

Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment terms: 50% advance payment; full payment for delivery

- Express delivery: FedEx, UPS, DHL

Key Features

- Purpose-built field termination

– Provides a tidy, serviceable interface between field devices and Triconex I/O modules. - Structured channel layout

– Numbered terminals with grouped commons make loop checks and proof testing faster in most cases. - Robust wiring hardware

– Industrial screw-clamp terminals and earth bonding points support dependable connections under vibration. - Direct I/O cabling

– Connects to the corresponding Triconex I/O card via the specified interface cable, minimizing wiring errors. - Cabinet-friendly footprint

– Panel or DIN-rail mounting options depending on bracket; fits standard control cabinets. - Service efficiency

– Clear labeling and front access help technicians trace signals quickly during turnarounds.

Technical Specifications

| Brand / Model | Triconex 4119A (Termination Assembly) |

|---|---|

| HS Code | 853890 (Parts for electrical control panels / programmable controllers) |

| Power Requirements | Passive assembly; no separate power in typical applications |

| Operating Temperature | Typically 0 to +60 °C, non‑condensing environment |

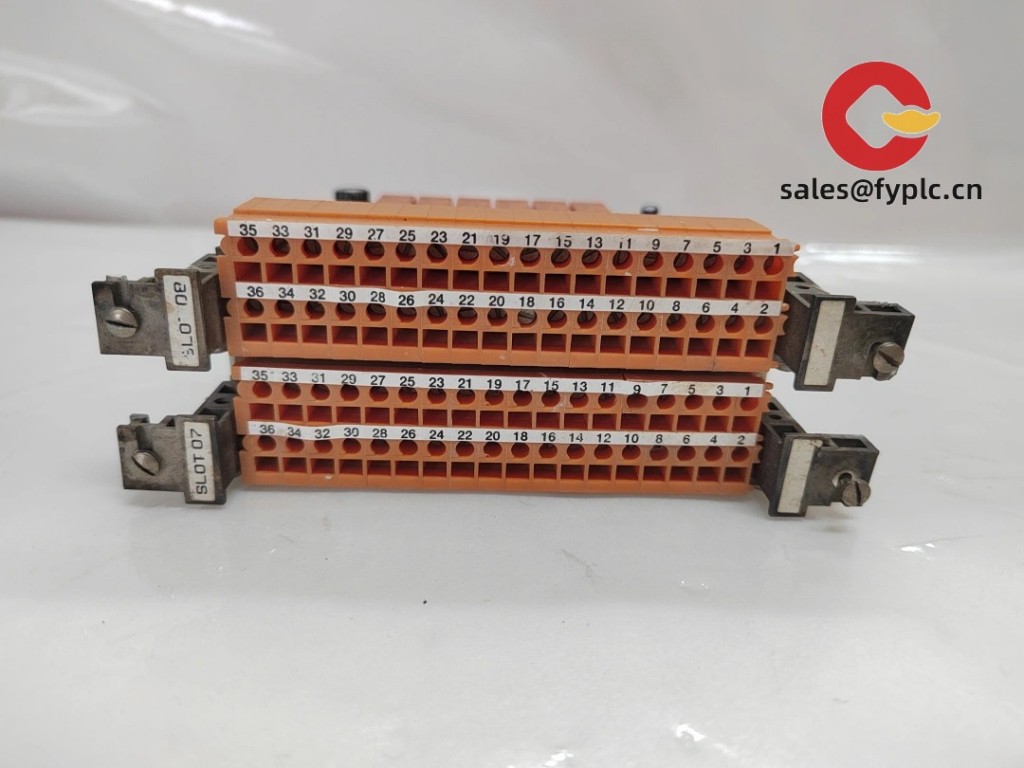

| Signal I/O Types | Field screw terminals interfacing to corresponding Triconex I/O modules via shielded interface cable |

| Communication Interfaces | Dedicated TA-to-I/O module cable (proprietary pinout per module type) |

| Installation Method | Panel or DIN‑rail mounting inside control cabinet; front-access terminals and labeling |

| Dimensions & Weight | Compact TA board format suitable for standard 600–800 mm cabinet depths (contact us for exact drawing if needed) |

Application Fields

The 4119A is typically used wherever Triconex safety I/O ties into hardwired plant signals and final elements. Practical examples include:

- Emergency Shutdown (ESD) cabinets – routing limit switches, pushbuttons, permissives to the controller.

- Fire & Gas (F&G) systems – landing detector relays, MCPs, sounders, and beacons.

- BMS/turbine protection – organizing interlocks and status contacts for fast, clean proof testing.

- Refining, petrochemical, LNG – high‑channel count terminations in SIL‑rated architectures.

- Power & utilities – breaker status and trip circuits interfacing to TMR logic.

Advantages & Value

- Reliability in the cabinet – Solid terminal hardware and clean layout reduce loose‑wire faults and nuisance issues.

- Compatibility – Intended for use with corresponding Triconex I/O modules, which simplifies design reviews and FAT.

- Cost-effective build – Predefined cable interfaces typically cut panel wiring time and error risk.

- Maintainable – Clear labeling and front access make loop checks and MOC work quicker.

- Support – Mature documentation and long lifecycle availability in the Tricon platform.

Installation & Maintenance

- Cabinet & environment – Mount in a clean, dry, ventilated cabinet within the stated temperature range; allow cable bend radius and labeling visibility.

- Wiring practices – Use ferruled conductors, observe torque specs, separate low‑level I/O from power lines, and bond shields per site grounding policy.

- Safety – Follow LOTO before touching field wiring; verify trip paths are bypassed per site procedure during work windows.

- Routine checks – Periodically re‑torque terminals, inspect for insulation damage, and verify channel identification plates.

- Spare strategy – Keep a spare TA and the correct interface cable on hand; it appears that swapping a TA is faster than re‑terminating in many cases.

Quality & Certifications

- Compliance – Typically CE compliant for the system assembly; many projects also reference UL/CSA and RoHS at the panel level.

- Use in SIL systems – Applied as part of Triconex TMR architectures that are certified to IEC 61508 up to SIL3 when engineered per the safety manual.

- Warranty – 365 days from delivery.

A site engineer told me after a turnaround, “With the 4119A, our loop checks ran smoother—labels were easy to follow and we didn’t chase ground noise.” That’s pretty much what you want from a termination assembly in a safety cabinet.

Reviews

There are no reviews yet.