Description

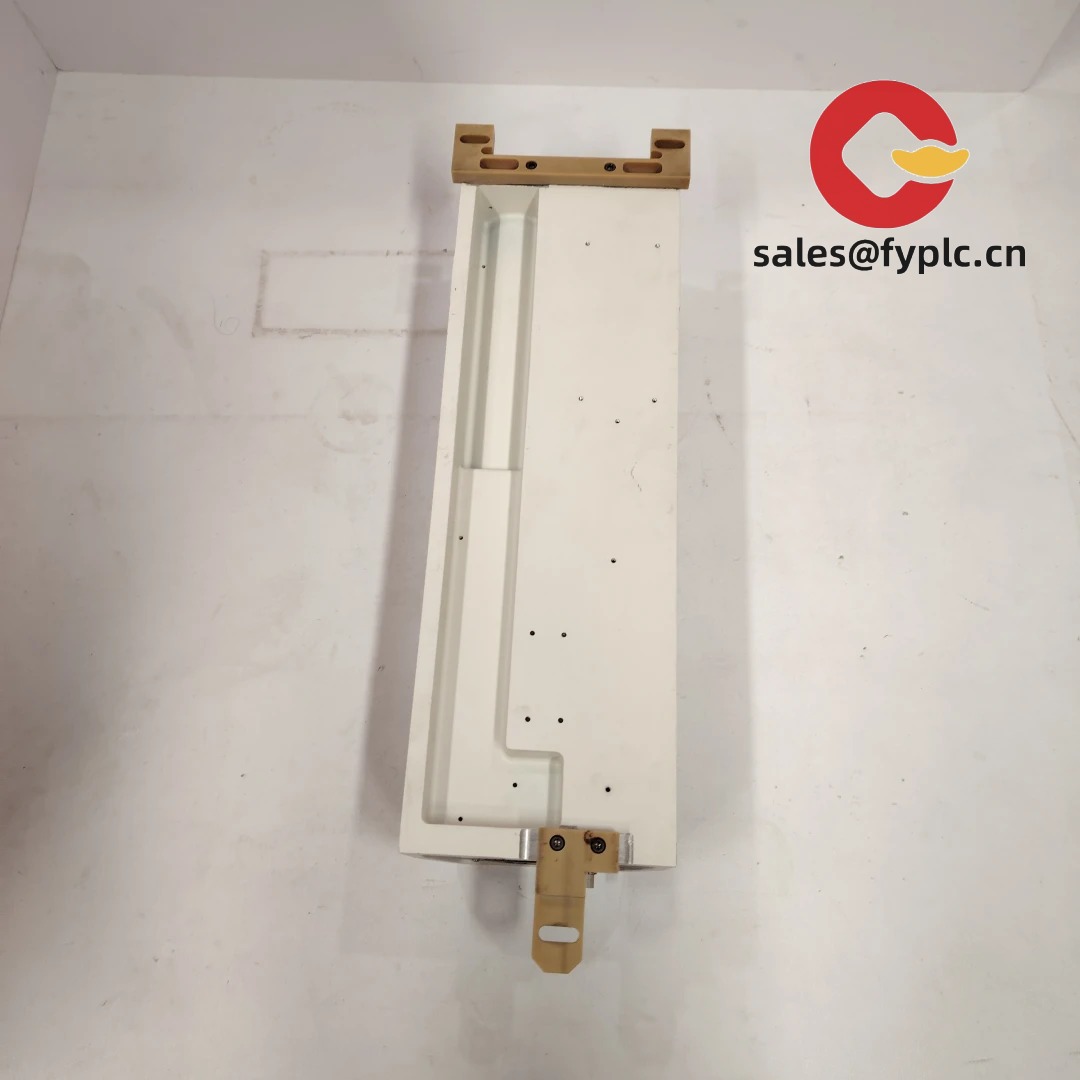

ZYGO 8070-0102-01X PC200 Interferometer Module – Precision displacement measurement for ZMI metrology systems

The ZYGO 8070-0102-01X_PC200 appears to be a ZMI-series plug‑in module used in heterodyne laser interferometer setups. From my experience, boards in this family live inside a ZYGO controller chassis and turn interferometer signals into real‑time position data with nanometer‑class stability—ideal when motion control and metrology need to agree perfectly. You might notice the PC200 designation in some BOMs; in many cases that points to the module’s role/version within a ZMI rack rather than the optics themselves.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Heterodyne interferometry engine

– Processes ZMI optical signals to produce stable, high‑resolution displacement data. - Deterministic real‑time outputs

– Position data presented to the host through the ZYGO backplane and encoder‑style signals (configuration dependent). - Multi‑axis capable

– Scales with optics/receivers for one or more axes; additional modules can expand channel count. - Integrated diagnostics

– Front indicators and software status help pinpoint alignment or signal issues quickly. - Low‑noise design

– Shielded paths and precision timing typically keep jitter and interpolation artifacts very low. - ZMI chassis integration

– Clean backplane power and communication; no ad‑hoc external power bricks required.

Technical Specifications

| Brand / Model | ZYGO 8070-0102-01X_PC200 (ZMI Interferometer Module) |

|---|---|

| HS Code | 903190 (Parts and accessories of measuring/checking instruments) |

| Power Requirements | Backplane powered by ZYGO ZMI chassis (low‑voltage rails; see system manual for current) |

| Operating Temperature | Typically 0 to +50 °C, non‑condensing, stable cabinet environment |

| Signal Input/Output Types | Interferometer measurement inputs from ZYGO receivers; position/encoder‑style outputs and trigger/status I/O (configuration dependent) |

| Communication Interfaces | ZYGO ZMI system backplane; front/edge connectors for shielded interferometer cabling |

| Installation Method | Plug‑in module for ZMI chassis; ESD‑safe handling; front status indicators for quick checks |

| Dimensions & Weight | Standard ZMI card format; fits compatible ZYGO controller slots |

Application Fields

This module is typically chosen when sub‑micron motion needs traceable, low‑drift feedback. Practical cases we see regularly:

- Semiconductor stages – wafer/reticle positioning with nanometer‑class repeatability.

- Precision optics – polishing and test benches requiring absolute displacement measurement.

- Ultra‑precision machine tools – linear and plane‑mirror interferometry used for closed‑loop control.

- Metrology & alignment systems – long‑travel axes needing reliable length calibration.

- Scientific instruments – synchrotron/beamline motion where drift must stay under tight limits.

Advantages & Value

- Measurement confidence – ZYGO’s heterodyne approach provides stable, traceable displacement data.

- Lower integration risk – Natively matches ZMI optics/receivers; fewer surprises than mixed‑vendor stacks.

- Throughput & yield – Deterministic outputs help motion controllers settle faster, often reducing re‑tunes.

- Serviceability – Indicators and structured diagnostics make it easier to separate optical from electrical issues.

- Lifecycle support – Well‑documented configurations and a sizable installed base simplify spares and migrations.

Installation & Maintenance

- Environment – Keep the rack in a clean, temperature‑stable enclosure; avoid airflow that creates thermal gradients across the optical path.

- Cabling – Use shielded interferometer cables; route away from VFDs/RF sources; bond shields per ZYGO guidance.

- Grounding – Single‑point grounding for chassis and optics mounts typically reduces noise and drift.

- ESD & handling – Power down per procedure; use ESD protection when inserting or removing the card.

- Routine checks – Verify signal contrast/strength, keep optics clean, and back up configuration; firmware should match your chassis revision.

Quality & Certifications

- Compliance – Typically CE; RoHS conformity is common for electronics in this class.

- Metrology alignment – Designed for use in ISO‑controlled precision measurement chains.

- Warranty – 365 days from delivery.

A customer on a precision optics line told me, “Once the optics were aligned, the ZMI module just tracked—no fuss during long runs.” That’s usually the value here: predictable, low‑drift feedback that lets your motion system do its job.

Reviews

There are no reviews yet.