Description

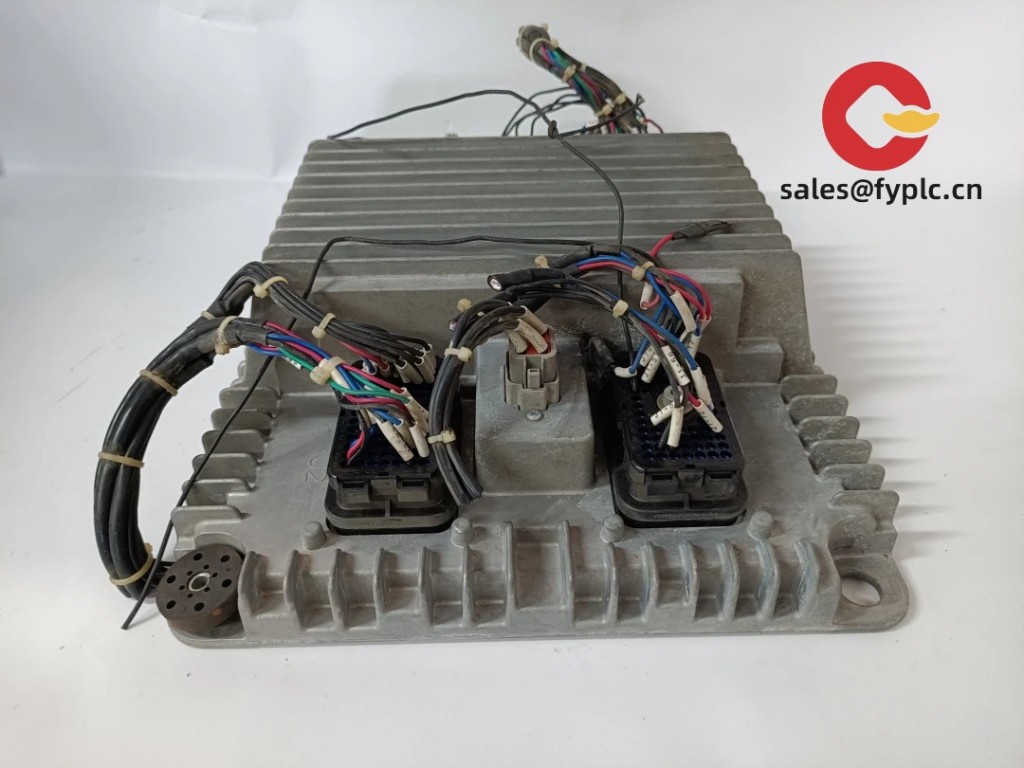

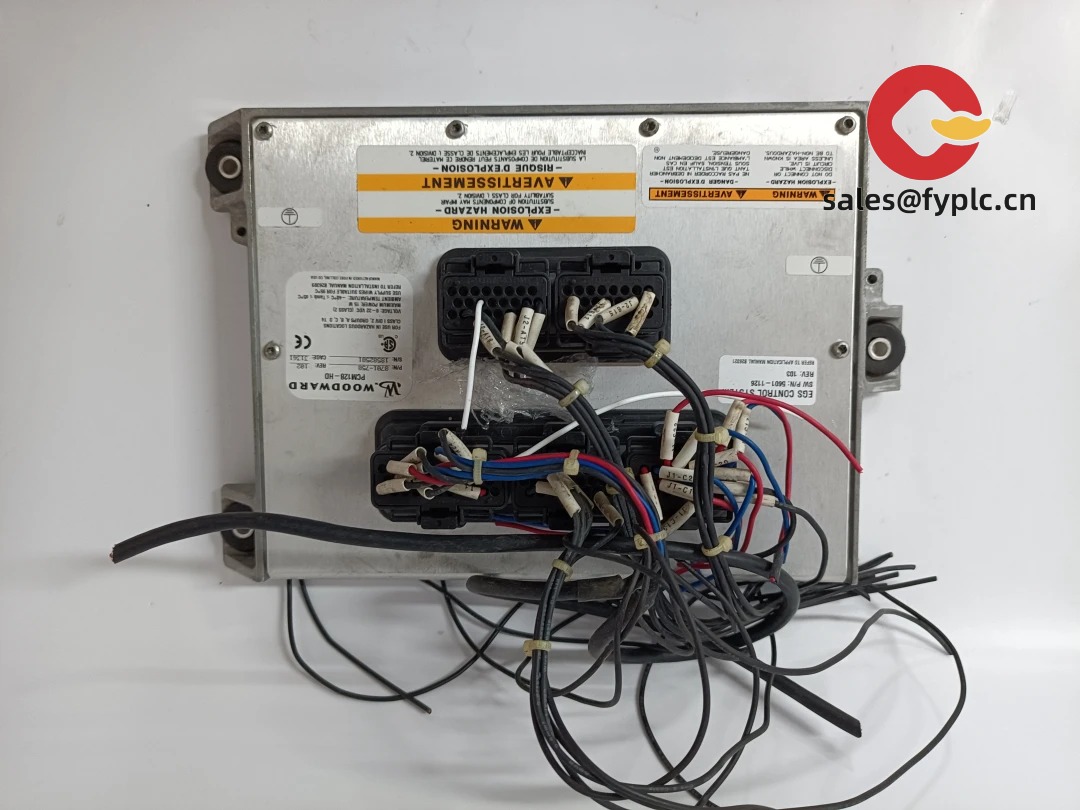

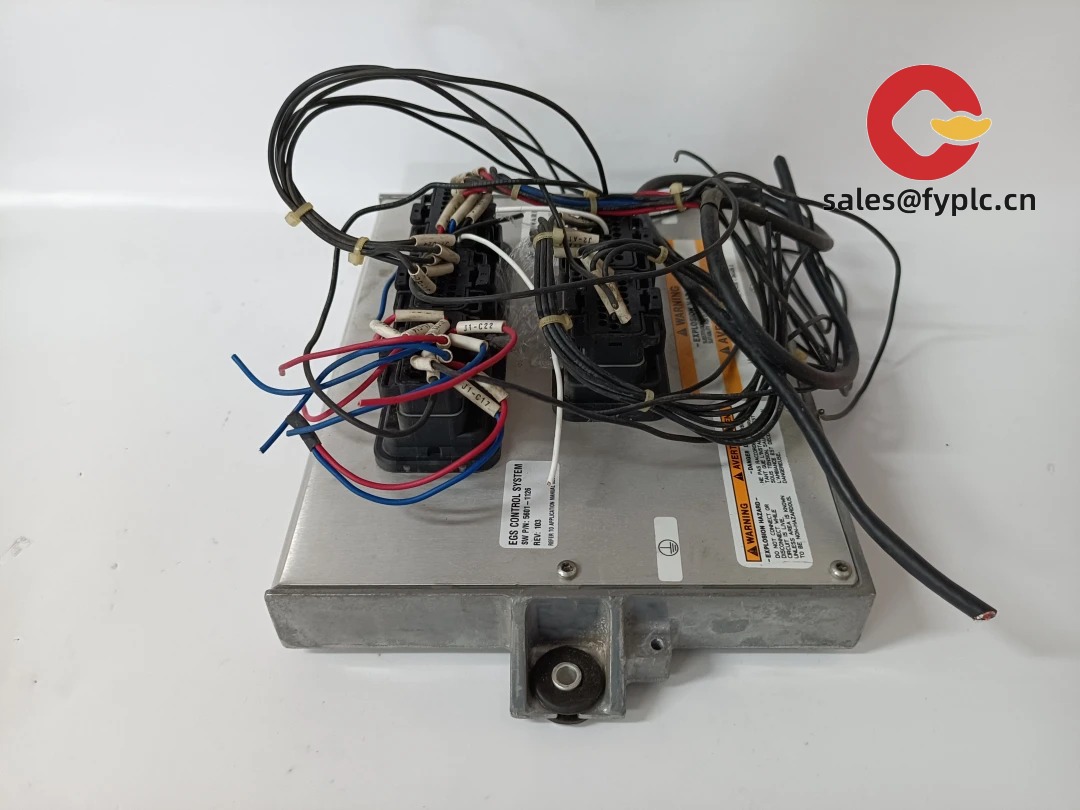

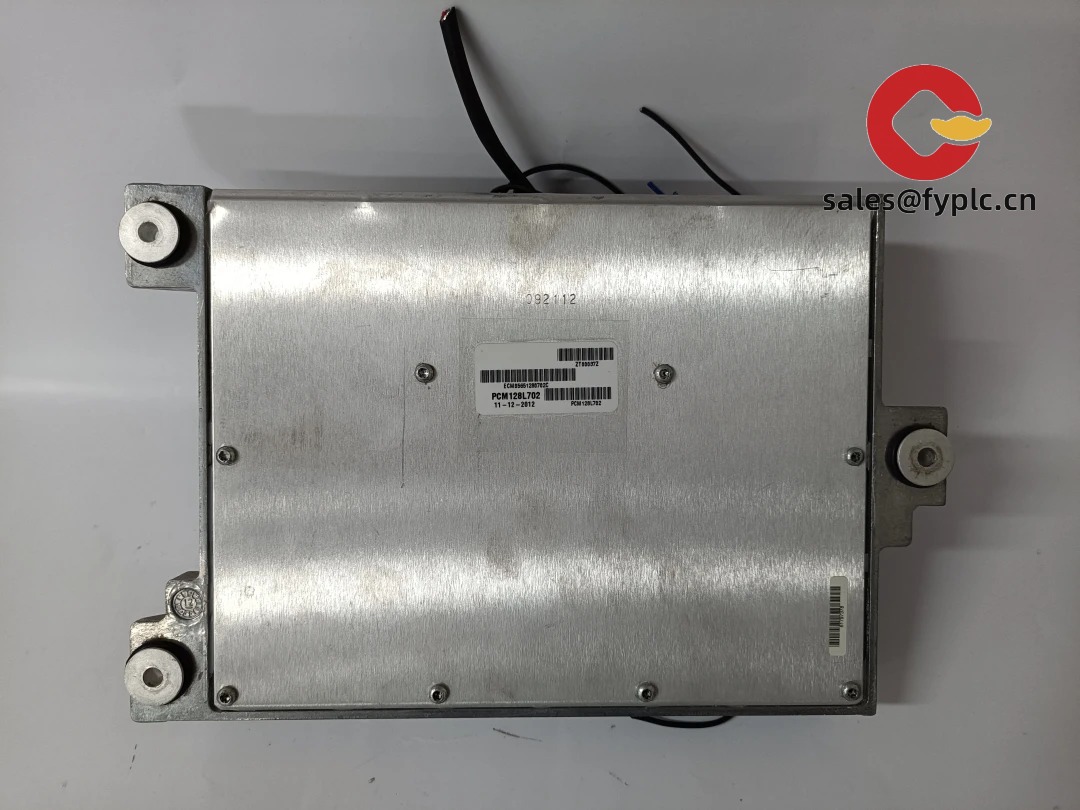

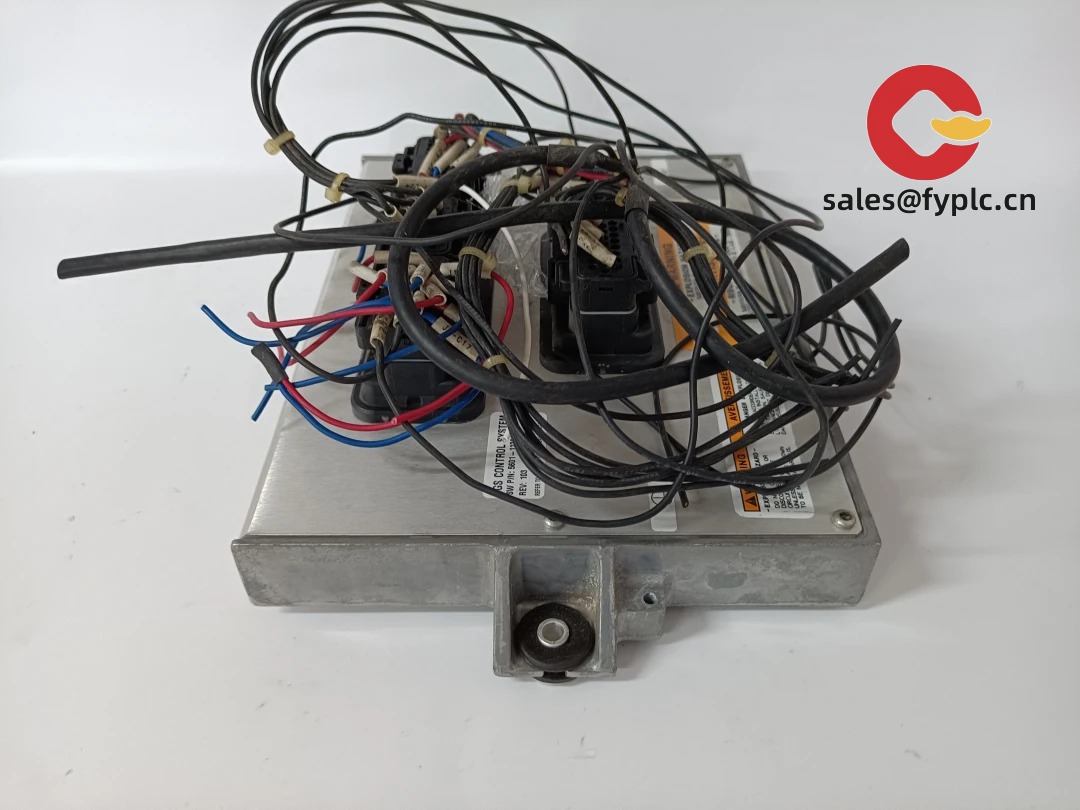

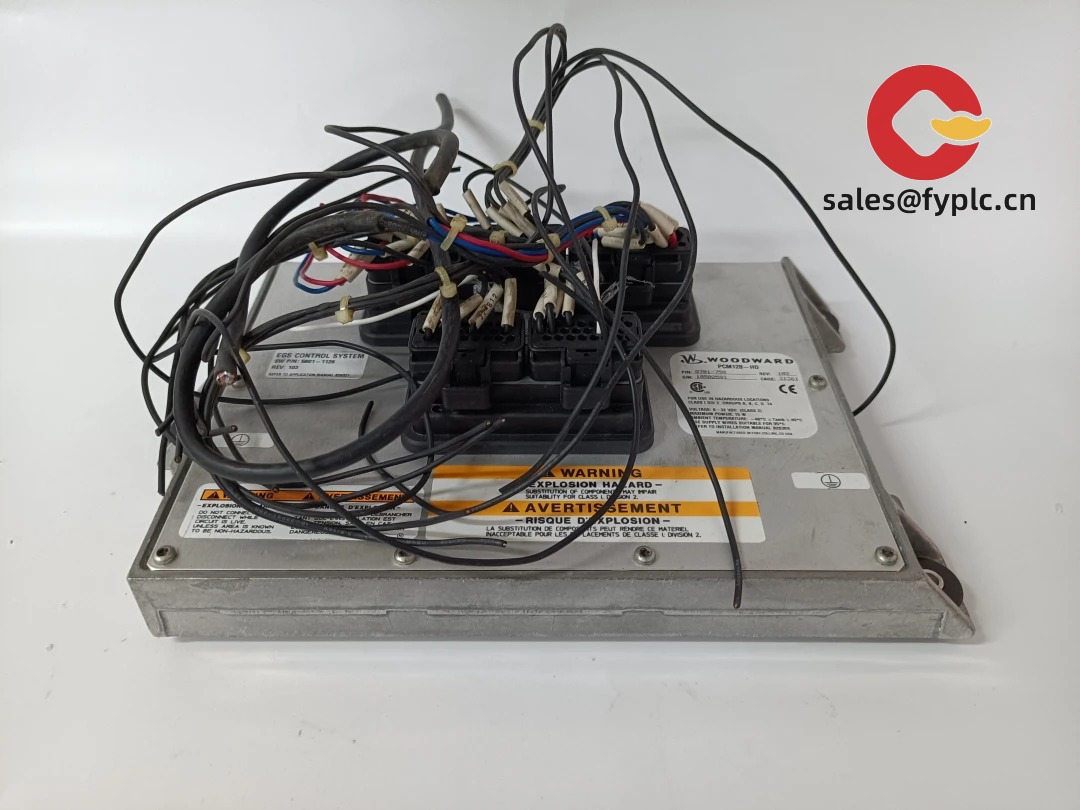

Woodward 8701-758 / 5601-1126 Termination Assembly & Interconnect Cable Set – Tidy, reliable field wiring for turbine control cabinets

This listing combines Woodward parts 8701-758 and 5601-1126, which in many projects are paired as a termination assembly with its matching interconnect cable. From my experience, sets like this sit between the rack I/O module and your field devices, giving you clearly labeled terminals and a direct, error‑resistant link to the controller. You might see the brand misspelled as “WOODBARD” in some places—this is Woodward hardware used widely in turbomachinery control panels.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Purpose-built termination

– Structured screw terminals with channel numbering make landing discrete and analog I/O straightforward. - Direct interface to controller I/O

– The 5601‑1126 interconnect cable mates the TA to the matching Woodward rack module, reducing cross‑wiring mistakes. - Shield and ground management

– Provisions for shield bonding help keep low‑level signals clean in electrically noisy cabinets. - Service-friendly layout

– Front access and clear labeling speed loop checks, proof testing, and SAT—usually where hours get saved. - Cabinet-ready mounting

– Panel/bracket mounting footprint that fits common wiring ducts and standard cabinet depths. - Rugged hardware

– Industrial screw‑clamp terminals and sturdy connectors hold up under vibration and frequent maintenance.

Technical Specifications

| Brand / Model | Woodward 8701-758 / 5601-1126 (Termination Assembly & Interconnect Cable) |

|---|---|

| HS Code | 853890 (Parts for electrical control panels / programmable controllers) |

| Power Requirements | Passive assembly; no separate power required |

| Operating Temperature | Typically 0 to +60 °C; non‑condensing cabinet environment |

| Signal I/O Types | Field screw terminals to proprietary interconnect cable matched to the corresponding Woodward I/O card |

| Communication Interfaces | Passive TA‑to‑module cable; pinout as per Woodward project/BOM specification |

| Installation Method | Panel or bracket mounting inside a control cabinet; front‑access terminals and label strips |

| Dimensions & Weight | Compact TA board format suitable for standard 600–800 mm cabinet depths (project drawing available on request) |

Application Fields

This set is typically used with Woodward turbomachinery controls—MicroNet and related platforms—depending on the project BOM. Practical uses I see often:

- Gas & steam turbine cabinets – landing permissives, trips, actuator feedback, and limit switches.

- Compressor anti‑surge/protection – organizing transmitter and valve I/O with clean shielding.

- Generator sets – breaker status/control, sync permissives, and balance‑of‑plant signals.

- Refining / petrochemical / LNG – high channel‑count terminations tied into SIL‑applied architectures.

- Power & utilities – neat, serviceable interfaces at the DCS/SIS boundary.

Advantages & Value

- Faster panel build – Predefined pinouts and label sequences typically cut wiring time and rework.

- Lower integration risk – Native fit to the matching Woodward I/O reduces cross‑terminations.

- Maintainable layout – Clear channels and shield provisions speed FAT/SAT and proof tests.

- Noise‑aware design – Proper earth/shield handling helps keep low‑level signals stable.

- Spares convenience – Keeping a like‑for‑like TA and cable on the shelf usually prevents outage delays.

Installation & Maintenance

- Cabinet & routing – Mount on a flat, ventilated panel; allow bend radius for the interconnect cable and space for ferrules/markers.

- Wiring practices – Use ferruled conductors; separate low‑level I/O from power/VFD runs; bond shields per site grounding policy.

- Safety – Apply LOTO on field circuits; if the connected I/O is trip‑critical, follow site bypass rules before work.

- Torque & inspection – Re‑torque terminals after heat cycles; check for insulation nicks and keep label strips legible.

- Documentation – Keep the pinout/map with the cabinet file; it typically prevents mis‑patching during fast turnarounds.

Quality & Certifications

- Compliance – Typically used within CE‑compliant cabinet assemblies; RoHS‑conformant components are common.

- Use in SIL projects – Applied as part of Woodward architectures that support IEC 61508 SIL levels when engineered per the safety manual.

- Warranty – 365 days from delivery.

A commissioning engineer told me after a turbine outage, “Once we had the correct TA and cable pair, every loop landed first time—no chasing cross‑wires.” That’s usually the quiet value these 8701‑758 / 5601‑1126 sets deliver.

Reviews

There are no reviews yet.