Description

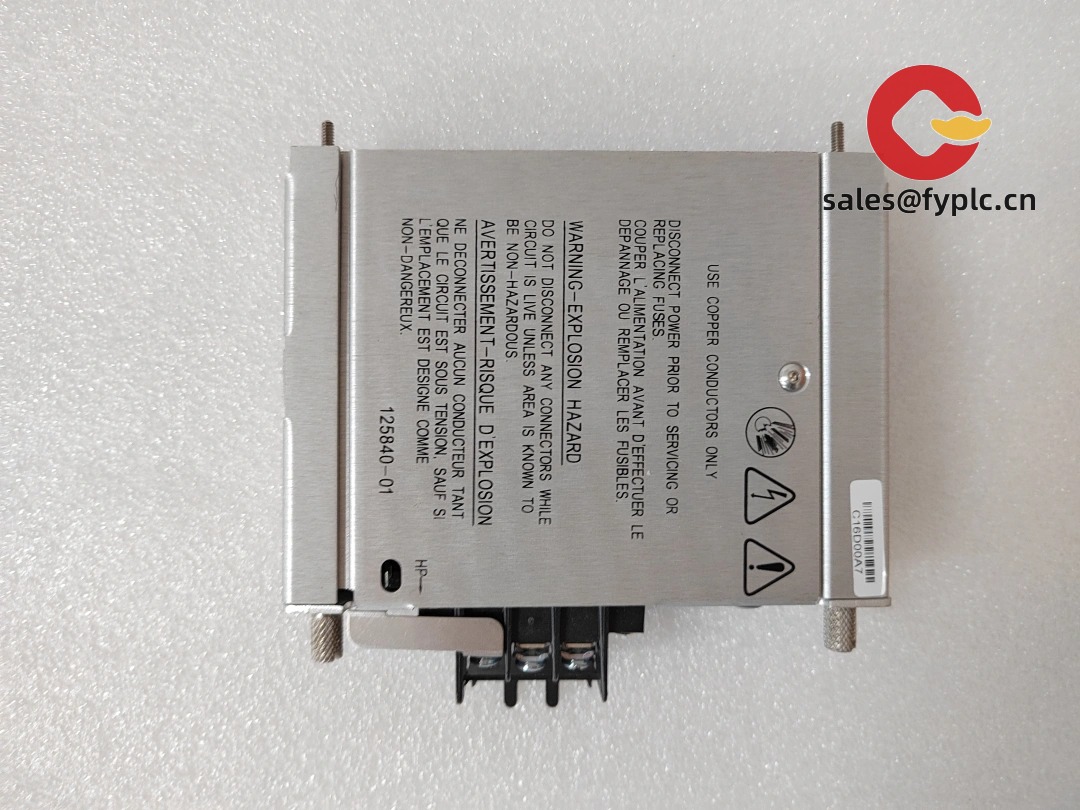

Bently Nevada 125840-01 – Rear I/O Module for 3500 Series Condition Monitoring Racks

The Bently Nevada 125840-01 is a rear I/O module used with 3500 series monitors to land field wiring and interface transducers to the rack. From my experience, it’s the piece that keeps your wiring clean and your channel mapping predictable—field signals in on clearly labeled terminals, conditioned and routed to the front‑mounted monitor card through the rack backplane. You might notice that maintenance teams like this arrangement because swap‑outs are quick and you don’t have to disturb the front monitor during routine service.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Designed for the 3500 platform – Mates with the corresponding 3500 monitor card; preserves channel order and labeling.

- Clean field terminations – Screw terminals (and, in some variants, BNC/test points) make loop checks and diagnostics straightforward.

- Backplane integration – Signals route through the rack backplane to the front monitor; no extra external jumpers.

- Service-friendly layout – Rear access means you can replace the I/O module without disturbing adjacent cards, which typically cuts downtime.

- Shielding and grounding provisions – Helps maintain signal integrity for proximity probes, seismic, and keyed speed inputs.

Technical Specifications

Specs reflect common characteristics for Bently Nevada 3500 rear I/O modules. If you share your front monitor part number and rack layout, we’ll confirm an exact match before shipment.

| Brand / Model | Bently Nevada 125840-01 |

| HS Code | 9031.90 (Parts of measuring or checking instruments) |

| Power Requirements | None; passive rear I/O module (interfaces via rack backplane) |

| Dimensions & Weight | Standard 3500 rear I/O form factor; fits the designated rear slot for the paired monitor |

| Operating Temperature | Industrial cabinet ambient; typically 0 to +65 °C when installed per rack guidelines |

| Signal Input/Output Types | Field screw terminals for proximity, seismic, Keyphasor, or transducer wiring (dependent on paired monitor module) |

| Communication Interfaces | Backplane interface to the front 3500 monitor; no network port on the I/O module itself |

| Installation Method | Rear rack mounting with captive screws; wire landing on labeled terminals; shield/earth provision provided |

Application Fields

- Centrifugal compressors and steam/gas turbines using proximity probes and Keyphasor pickups

- Pumps, motors, and fans where continuous vibration and axial position monitoring is required

- Balance-of-plant machines tied into a 3500 rack for alarms, trips, and historical condition data

- Retrofits where preserving existing probe and cable runs is a priority

Advantages & Value

- Reliability – Passive I/O with clear terminations; easier to verify during loop checks and shutdown testing.

- Compatibility – Built for the 3500 ecosystem; in most cases it’s a direct replacement with no rewiring.

- Cost control – Shortens outage time and reduces the risk of wiring mistakes that lead to nuisance alarms.

- Support – We can validate monitor/I/O pairings and rack slotting so installation is right the first time.

Installation & Maintenance

- Rack mounting – Install on the rear of the 3500 rack aligned to the matching front monitor. Tighten captive screws evenly.

- Wiring – Land probes/shields per the wiring diagram; keep low‑level signals away from VFD outputs and contactor wiring.

- Grounding – Bond shields and rack earth per site EMC practice; avoid ground loops by following the single‑point scheme.

- ESD handling – Treat as ESD‑sensitive; use a grounded wrist strap during replacement.

- Routine checks – Re‑torque terminals during PMs, inspect for insulation wear, and confirm channel health in System 1 (where applicable).

Quality & Certifications

- CE and RoHS compliance (typical for Bently Nevada rack components)

- UL/cUL suitability for industrial control panels, model dependent

- Manufacturer’s warranty: 12 months from shipment

If you can share your front monitor part number (3500/xx), rack revision, and the transducer type on each channel, we’ll verify that 125840-01 is the correct rear I/O and line up a fast shipment to fit your maintenance window.

Reviews

There are no reviews yet.