Description

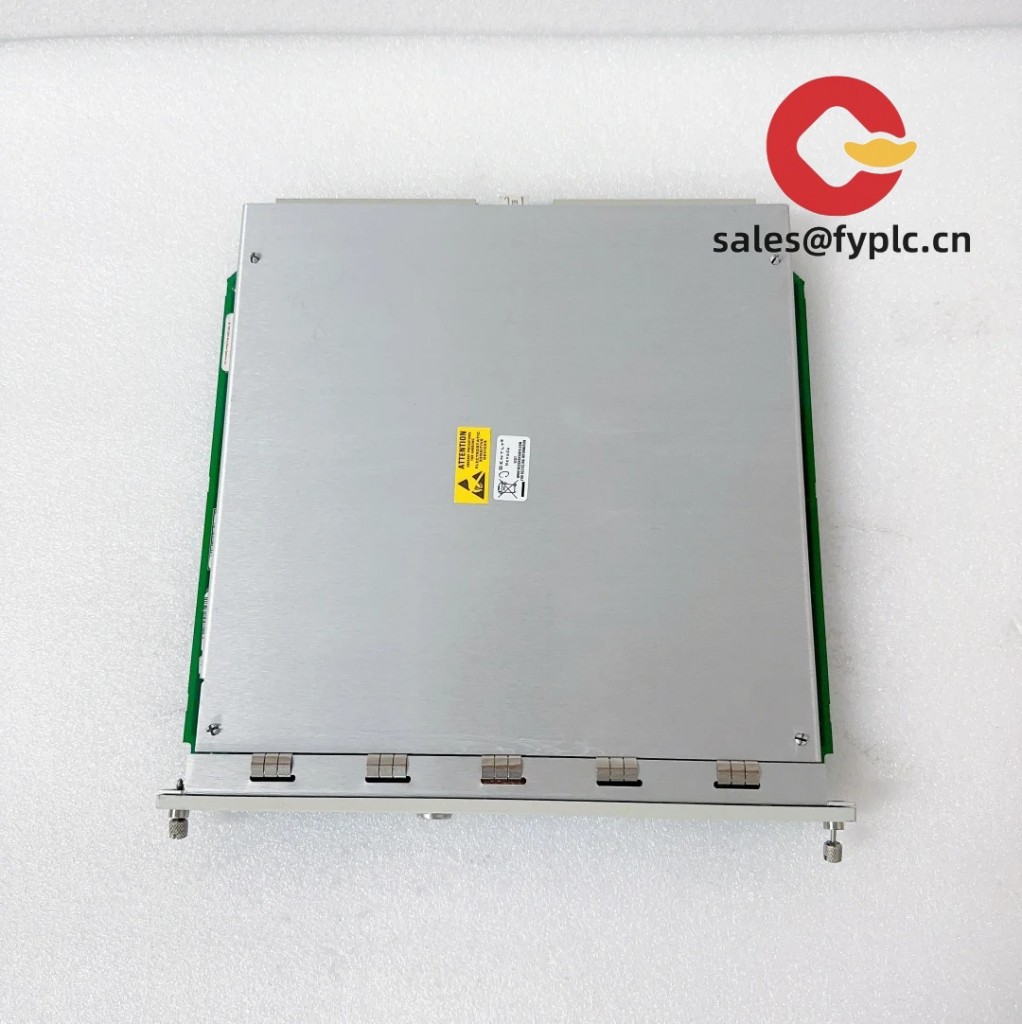

Bently Nevada 350020_125744-02 – 3500/20 Relay Module with 125744-02 Rear I/O Plate

The code 350020_125744-02 denotes a Bently Nevada 3500/20 Relay Module paired with its matching rear I/O termination plate 125744-02. From my experience, this is the go‑to module when you want clean, deterministic alarm and trip contacts from a 3500 rack—map channel alarms, system OK, and voting logic to dry contacts that your DCS/ESD understands. You might notice that keeping the OEM rear plate in place typically shortens outage work because wiring stays tidy and clearly labeled.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Native 3500 alarm relays – Converts 3500 rack alarms and status into dry‑contact outputs for DCS/ESD/MCC interfaces.

- Paired rear I/O (125744-02) – Labeled terminals for quick field termination; simplifies loop checks and maintenance.

- Configurable alarm logic – Supports mapping of channel and system alarms with voting options typically used in machinery protection.

- Backplane powered – Draws power from the 3500 rack; no separate supply wiring.

- Service-friendly design – Front plug‑in module and rear terminals mean faster swap‑outs during shutdown windows.

Technical Specifications

Values below reflect commonly expected characteristics for a 3500/20 Relay Module with its matching rear I/O. If you share your rack option string and alarm mapping, we’ll verify the exact configuration before shipment.

| Brand / Model | Bently Nevada 350020-125744-02 (3500/20 + rear I/O 125744-02) |

| HS Code | 9031.90 (Parts of measuring or checking instruments) |

| Power Requirements | Powered via 3500 rack backplane (through 3500/15 power supply) |

| Dimensions & Weight | Standard 3500 front module width with matching rear plate footprint |

| Operating Temperature | Typically 0 to +65 °C when installed per 3500 rack guidelines |

| Signal Input/Output Types | Dry‑contact relay outputs on rear terminals; alarm/status mapping configured in the 3500 system |

| Communication Interfaces | Backplane interface within the 3500 rack (no external network port on this module) |

| Installation Method | Front plug‑in to 3500/05 chassis; wire contacts to the 125744‑02 rear I/O plate |

Application Fields

- Compressor, turbine, and large motor trains where 3500 alarms must drive trips/interlocks

- Balance‑of‑plant assets needing discrete alarm contacts for DCS or annunciator panels

- Units standardizing on 3500 hardware for consistent alarm logic and cabinet wiring

- Retrofits that aim to keep existing contact wiring but refresh relay hardware

Advantages & Value

- Reliability – Purpose‑built relay module for machinery protection; fewer workarounds and cleaner diagnostics.

- Compatibility – Native to the 3500 ecosystem; in most cases a like‑for‑like swap with no wiring changes.

- Maintainability – Rear terminations and clear legends make loop checks faster, typically shortening outage time.

- Procurement confidence – Traceable parts with a 365‑day warranty support critical spares planning.

Installation & Maintenance

- Mounting – Seat the front module fully in the 3500/05 chassis; secure the 125744‑02 rear plate with captive screws.

- Wiring – Land relay contacts to your DCS/ESD per drawings; keep low‑level transducer wiring segregated from relay cabling.

- Grounding – Bond the rack and shields per single‑point grounding practice to avoid loops.

- Commissioning – Verify alarm mapping and any voting logic; function‑test contact operation at the DCS/ESD.

- Routine care – Re‑torque terminals during PMs, inspect for wear, and check module status indicators.

Quality & Certifications

- CE and RoHS compliance (typical for Bently Nevada rack components)

- UL/cUL suitability for industrial control panels, model dependent

- Manufacturer’s warranty: 12 months from shipment

Share your rack option string, alarm mapping, and whether you’re using redundant power. We’ll confirm the 350020 + 125744‑02 pairing so the changeout is a smooth, first‑pass success.

Reviews

There are no reviews yet.