Description

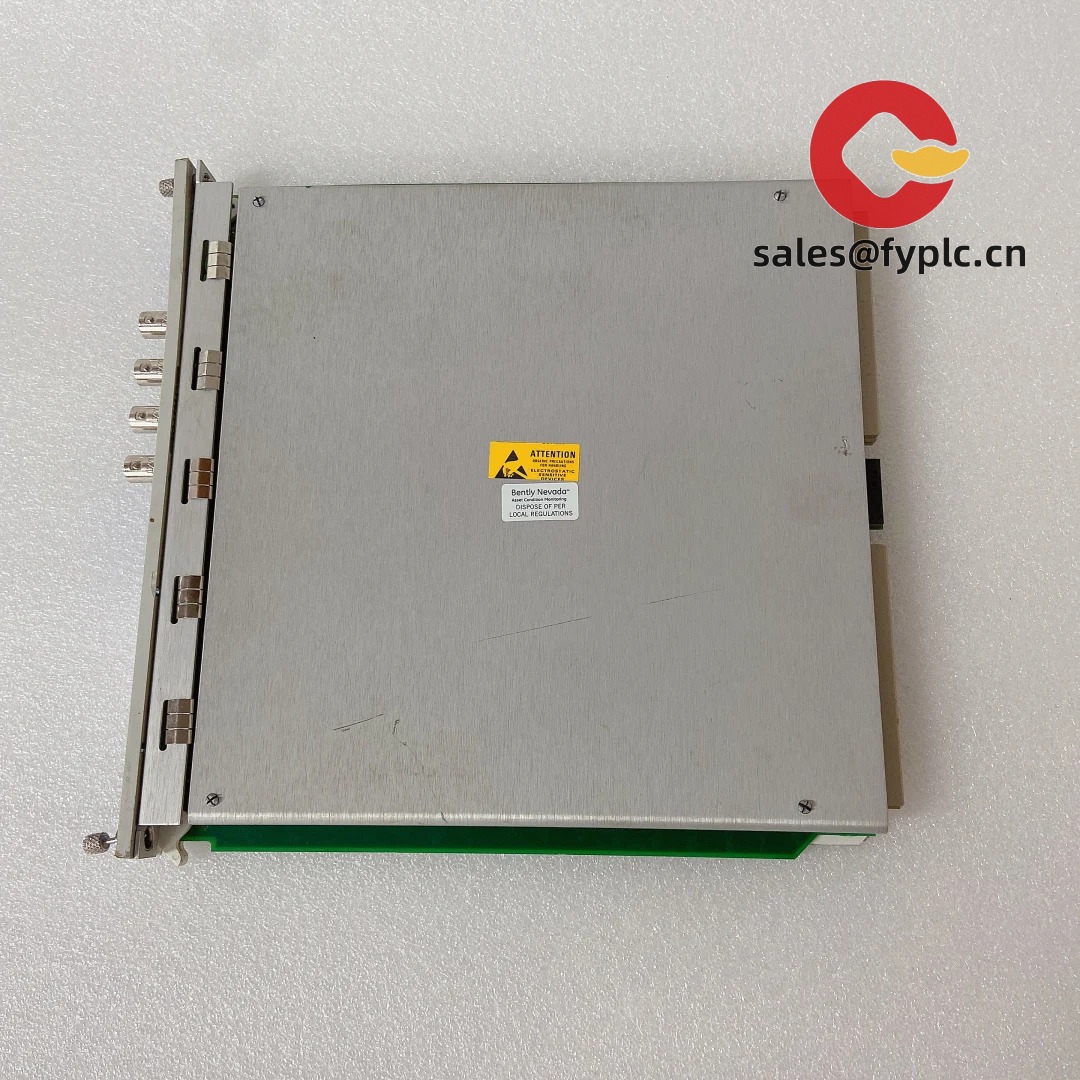

Bently Nevada 350044M-176449-03 – 3500/44M Proximitor/Seismic Monitor with 176449-03 Rear I/O Plate

The Bently Nevada 350044M-176449-03 pairs a 3500/44M machinery monitor with its matching rear termination plate 176449‑03. From my experience, this model is used much like the 40M/42M family—four channels for proximity probes and, in many cases, seismic transducers—so you can cover radial vibration, thrust (axial) position, and casing velocity/acceleration in one slot. One thing I appreciate is how the revision‑matched rear plate keeps shield landings consistent and makes swap‑outs feel almost routine during a turnaround.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- Four-channel monitoring – Typically supports proximity probe drivers and seismic sensors for radial vibration, thrust position, and casing vibration.

- Matched rear I/O (176449‑03) – Clearly labeled screw terminals and earth points help keep terminations tidy and traceable.

- Integrated alarms – Configurable Alert/Danger thresholds with OK status so testing and interlocks are predictable.

- Backplane integration – Powered via the rack; data and status share internally to relay modules and the 3500/22M TDI.

- Service‑friendly layout – Front plug‑in card with rear terminations usually shortens outage tasks and reduces wiring errors.

Technical Specifications

Specs below reflect the typical characteristics for a 3500/44M when paired with the 176449‑03 rear plate. If you share your probe types and rack option string, we’ll verify the exact fit before shipment.

| Brand / Model | Bently Nevada 350044M-176449-03 (3500/44M + rear I/O 176449‑03) |

| HS Code | 9031.90 (Parts of measuring or checking instruments) |

| Power Requirements | Powered via 3500 rack backplane (through 3500/15 power supply); no separate PSU to the module |

| Operating Temperature | Typically 0 to +65 °C when installed per 3500 rack guidelines |

| Dimensions & Weight | Standard 3500 single‑slot front module with matched rear plate footprint |

| Signal Input/Output Types | Up to 4 transducer inputs (proximitor drivers or seismic velocity/acceleration, configuration dependent); alarms realized via rack relay modules |

| Communication Interfaces | Internal 3500 backplane; external data access through 3500/22M TDI (Ethernet on TDI) |

| Installation Method | Front plug‑in to 3500/05 chassis; land transducer wiring on the 176449‑03 rear plate; use provided shield/earth points |

Application Fields

- Compressors and turbines monitoring radial vibration, thrust position, and casing vibration

- Large motors, pumps, and fans where continuous vibration trending supports protection and reliability

- Gearboxes and critical balance‑of‑plant assets needing 4‑channel coverage in a single card

- Retrofits aiming to keep probe runs intact while refreshing rack hardware

Advantages & Value

- Reliability – Predictable OK/Alert/Danger behavior; easier to validate during loop checks.

- Compatibility – Native fit with the 3500 ecosystem and Bently probes; in many cases a like‑for‑like replacement.

- Maintenance efficiency – Rear labeling and shield points help technicians move faster and reduce wiring mistakes.

- Risk control – Stable option coding with a 365‑day warranty tends to de‑risk shutdown planning.

Installation & Maintenance

- Probe setup – Set proximity gaps/targets per spec; for seismic sensors, verify orientation and mounting torque.

- Wiring practice – Keep low‑level transducer wiring away from VFD outputs and contactor bundles; maintain shield continuity at the designated point.

- Grounding – Bond the rack using single‑point practice; use the rear plate earth lugs to avoid loops.

- Commissioning – Confirm OK status, scaling, and Alert/Danger thresholds; verify data visibility through the 22M into System 1.

- Routine care – Re‑torque terminals during PMs, inspect probe cables/insulation, and review trend/OK logs for early warnings.

Quality & Certifications

- CE and RoHS compliance (typical for Bently Nevada 3500 components)

- UL/cUL suitability for industrial control panels, model dependent

- Manufacturer’s warranty: 12 months from shipment

If you share your transducer models (proximity or seismic), channel assignments, and the rack option string, we’ll double‑check the 3500/44M + 176449‑03 pairing and line up a shipment that fits your maintenance window.

Reviews

There are no reviews yet.