Description

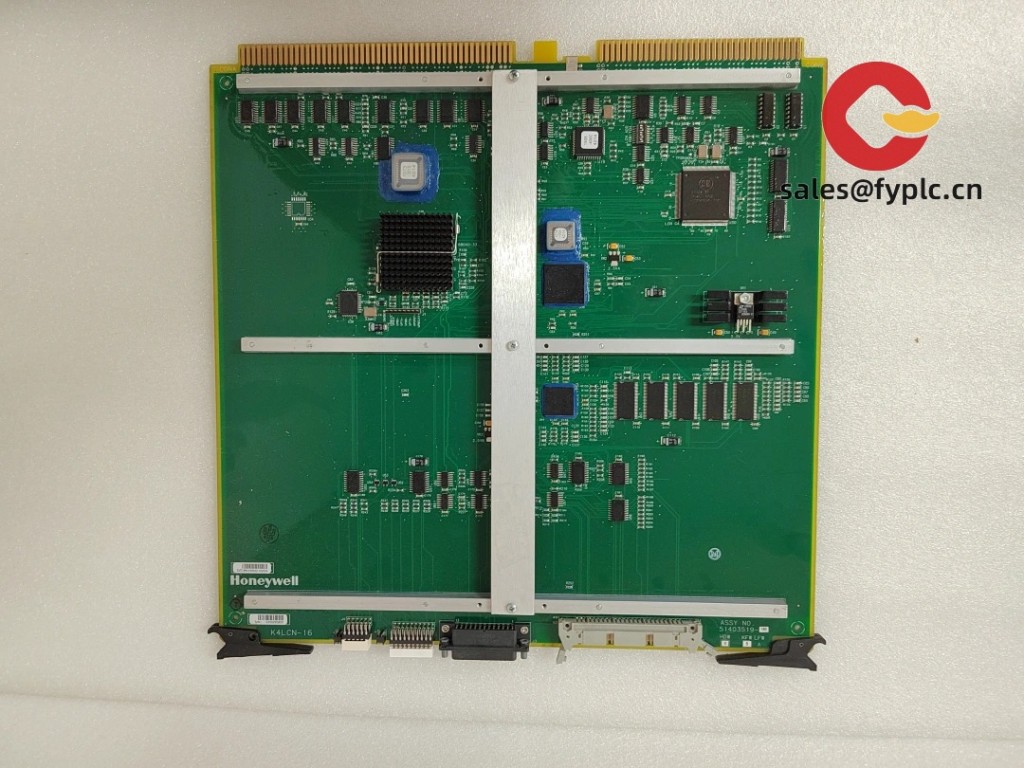

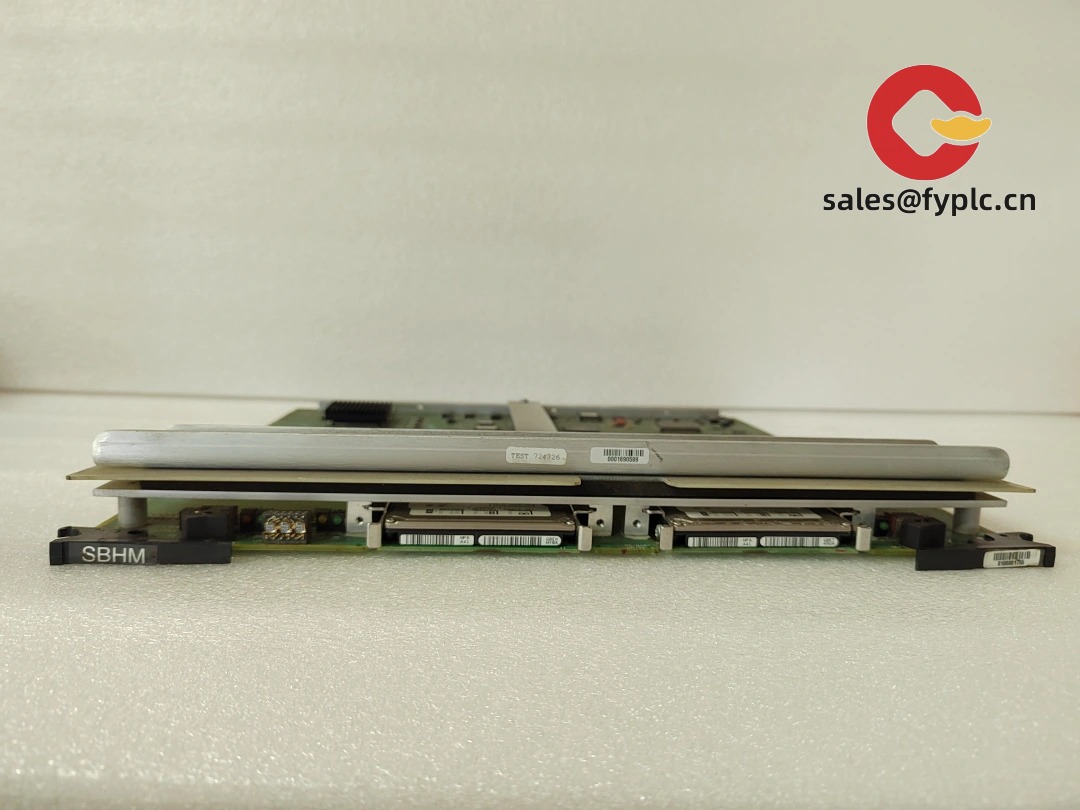

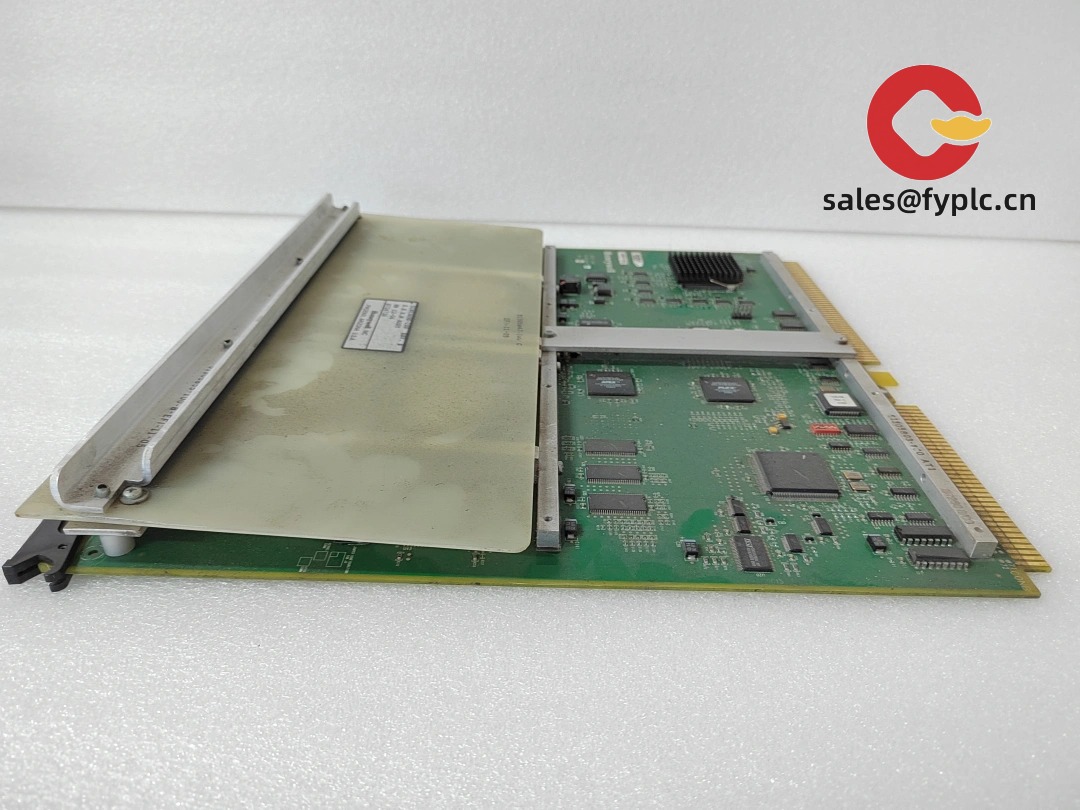

Honeywell 51403645-100 / SBHM – System Bus Head Module for TDC/TPS Node Integration

Honeywell 51403645-100, labeled SBHM, is used on classic TDC 3000 / TPS nodes to interface the chassis to the System Bus (SBUS). From my experience, it’s the piece that stabilizes node communications on the cabinet bus—slot it in, land the bus connection, and the node typically rejoins the segment without touching the rest of the wiring. You might notice that plants keep an SBHM on the shelf because a like‑for‑like swap seems to turn bus faults into quick recoveries during tight outage windows.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock; no more than 1 month at the latest

- Payment method: 50% advance payment; full payment for delivery

- Express delivery methods: FedEx, UPS, DHL

Key Features

- System Bus interface (SBUS) – Provides the node’s physical/logical connection to the cabinet bus so controllers, stations, and modules stay synchronized.

- Backplane integration – Draws low‑voltage rails and signals through the Honeywell node chassis; no extra PSU wiring.

- Drop‑in replacement – In many cases, a one‑for‑one board swap restores bus communications with no cabinet rewiring.

- Service‑friendly terminations – Clearly identified connectors help technicians re‑land the bus quickly and check status.

- Built for control‑room duty – Stable, continuous operation under ambient conditions typical of DCS cabinets.

Technical Specifications

Specs reflect what’s commonly associated with SBUS head/interface modules in this Honeywell family. Share your node tag and bus topology and we’ll confirm the exact fit before shipment.

| Brand / Model | Honeywell 51403645-100 / SBHM |

| HS Code | 8538.90 (Parts suitable for industrial control equipment) |

| Power Requirements | Backplane‑supplied (low‑voltage logic rails); no external PSU to the module |

| Operating Temperature | Control‑room ambient; typically 0 to +50/60 °C |

| Dimensions & Weight | Plug‑in module form factor for Honeywell node chassis; approx. 0.4–0.6 kg (module‑only, typical) |

| Signal Input/Output Types | System Bus trunk connection (coax or twisted‑pair, revision/site‑standard dependent); backplane interface to node electronics |

| Communication Interfaces | Honeywell SBUS segment; termination and impedance follow site SBUS specification |

| Installation Method | Front plug‑in to node chassis; connect SBUS; verify segment termination/end‑of‑line rules |

Application Fields

- TDC 3000 / TPS control rooms maintaining cabinet System Bus connectivity between nodes and stations

- Brownfield upgrades keeping SBUS infrastructure while refreshing node hardware

- Network spares for sites that standardize on OEM modules to reduce MTTR

- Extensions or repairs of existing bus segments within complex DCS cabinets

Advantages & Value

- Low integration risk – Typically a drop‑in fit that preserves wiring and node configuration.

- Uptime protection – A verified spare SBHM often turns a bus fault into a same‑shift recovery.

- Compatibility – Designed for Honeywell node backplanes and approved SBUS cabling/terminations.

- Traceability – Clear part coding supports maintenance records and outage planning.

Installation & Maintenance

- ESD handling – Treat as ESD‑sensitive; use a grounded wrist strap and antistatic surface.

- Bus practices – Match the site’s SBUS medium (coax/twisted‑pair), impedance, and termination; maintain bend radius and strain relief.

- Routing – Keep the bus path clear of high‑EMI conductors and VFD cabling.

- Commissioning – Verify node health on the bus, check error counters, and confirm redundancy/peer visibility where applicable.

- Routine checks – Inspect connectors for oxidation; re‑seat and clean during PMs if needed and document topology changes.

Quality & Certifications

- UL/CE conformity typical for control‑room modules (revision dependent)

- RoHS status varies by vintage; we can confirm against your required build

- Manufacturer’s warranty: 12 months from shipment

If you share the cabinet tag, node type, and SBUS topology (medium, termination scheme), we’ll validate the 51403645‑100 / SBHM match and ship on a schedule that fits your outage plan.

Reviews

There are no reviews yet.