Description

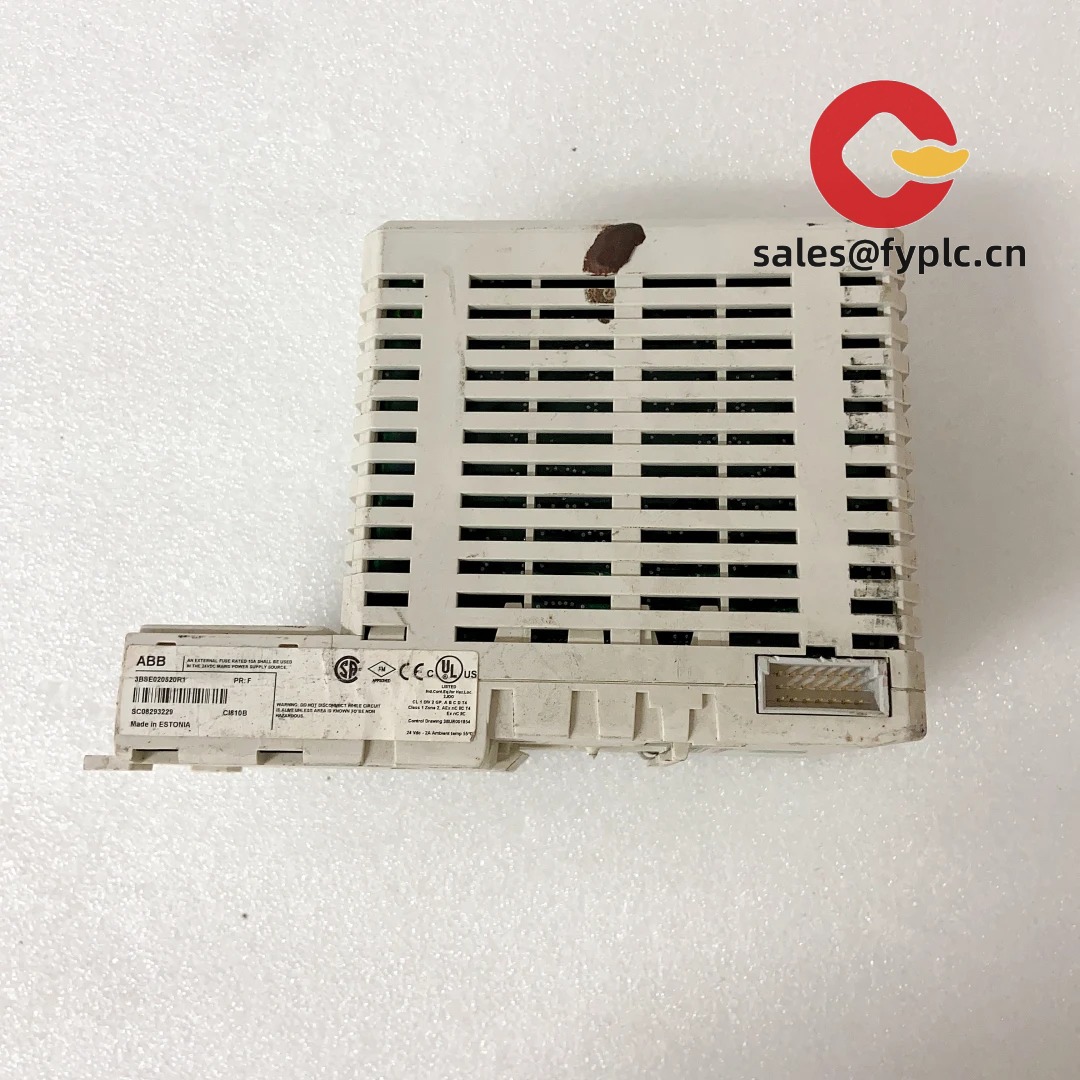

ABB CI810B (3BSE020520R1) – Communication Interface for AC 800M to S800 I/O ModuleBus

The ABB CI810B is a communication interface module designed to bridge an AC 800M controller to S800 I/O over ModuleBus. From my experience, it’s the go‑to piece when you want reliable, redundant-ready I/O connectivity without reshaping your entire cabinet layout. It appears to be a favorite in brownfield upgrades too—swap a failing unit, reload the config, and you’re back online with minimal downtime.

Order Placement Process & Guarantees

- Warranty: 365 days

- Lead time: typically 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment, balance before delivery

- Express options: FedEx, UPS, DHL

Key Features

- AC 800M to S800 I/O ModuleBus interface – Purpose-built link for S800 I/O islands via the ABB ModuleBus.

- CEX‑Bus integration – Mounts on the AC 800M CEX‑Bus, so no separate controller slot changes are needed.

- Redundancy-friendly topology – Typically supports dual ModuleBus lines and high availability architectures used in process industries.

- No user I/O channels – Streamlined communications module; all field signals live on the S800 I/O side.

- Stable timing and diagnostics – Works with AC 800M engineering tools for diagnostics; you can quickly verify bus health during commissioning.

- Drop‑in replacement – In many cases, a direct swap for CI810 variants with minimal re-engineering.

Technical Specifications

| Brand / Model | ABB CI810B (Order code: 3BSE020520R1) |

| HS Code | 8537.10 (Programmable controllers / control panels) |

| Power Requirements | Supplied via AC 800M CEX‑Bus; 24 V DC from controller backplane (no separate PSU; typical low power draw) |

| Operating Temperature | 0 to +55 °C (cabinet installation; typical for AC 800M environment) |

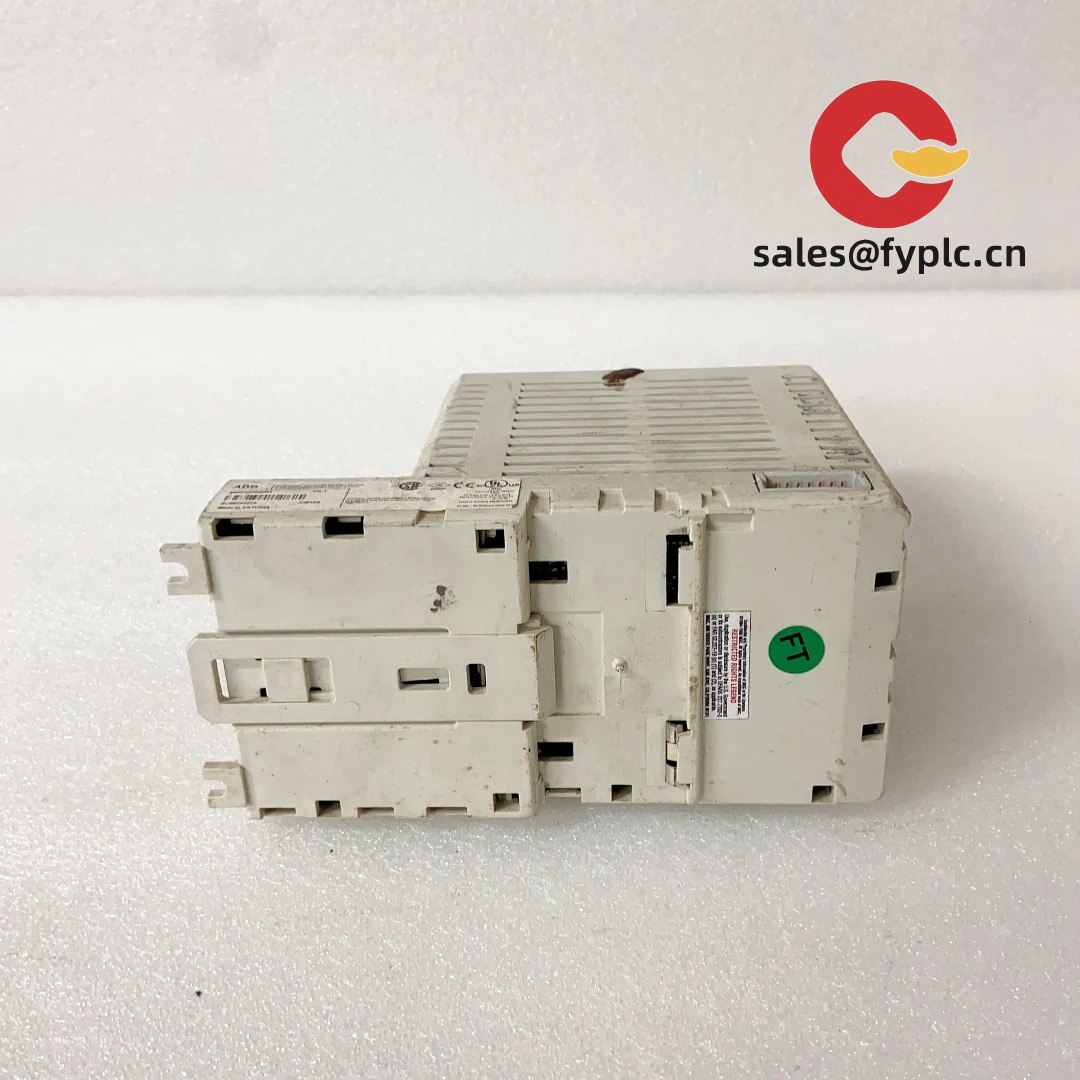

| Dimensions & Weight | Compact CEX‑module form factor; single‑width footprint; typical weight < 0.3 kg |

| Signal I/O Types | No direct field I/O; provides ModuleBus communications only |

| Communication Interfaces | CEX‑Bus (to AC 800M), ModuleBus (to S800 I/O; dual/redundant line capability in typical designs) |

| Installation Method | DIN‑rail cabinet mounting with CEX‑Bus connection; ModuleBus daisy‑chain to S800 I/O islands |

Application Fields

You’ll typically find CI810B used wherever AC 800M teams rely on S800 I/O: continuous process plants, power & utilities, chemicals, oil & gas, water/wastewater, pulp & paper, and mining. One thing I appreciate is how well it fits phased migration projects—keep the I/O islands, change only what’s necessary near the controller, and avoid long outages.

Advantages & Value

- Reliability – Proven stability in 24/7 environments; ModuleBus diagnostics help spot wiring or segment issues early.

- Compatibility – Designed for AC 800M and S800 I/O; typically works within existing 800xA architectures.

- Cost Savings – Reuse of S800 I/O infrastructure, fewer cabinet changes, and shorter shutdown windows.

- Straightforward Replacement – Swap-and-configure approach reduces engineering time for maintenance teams.

- Support Ecosystem – Abundant field knowledge and spare availability make lifecycle support simpler.

Field note: a maintenance lead at a water treatment plant told us they replaced a CI810B during a 4‑hour downtime window—reconnected ModuleBus, verified nodes in the engineering tool, and had their entire S800 rack visible again before shift change.

Installation & Maintenance

- Cabinet & Environment – Mount on DIN rail in a clean, ventilated cabinet. Aim for 0…+55 °C and avoid condensation or corrosive atmospheres.

- Wiring – Keep ModuleBus cabling consistent (impedance, shielding, and grounding). Maintain proper daisy‑chain practices and segment termination per ABB guidelines.

- Power – Uses controller‑provided 24 V DC via CEX‑Bus; verify stable cabinet supply and grounding to reduce noise.

- Commissioning – Add/verify the module in your AC 800M project (typically via Control Builder M), check ModuleBus node addressing, then download configuration.

- Maintenance – Periodically inspect connectors, tighten terminals, and clean dust. Keep firmware and project libraries aligned with site standards before making changes.

- Spare Strategy – Keeping one CI810B spare per controller family on site seems to be a practical approach for high‑availability assets.

Quality & Certifications

- CE marked; UL recognition is commonly available for AC 800M ecosystem components

- RoHS compliant design in most deliveries

- Manufacturer warranty practices apply; sales warranty coverage: 365 days

Related/Supporting Components (for planning)

- AC 800M controllers (e.g., PM861/PM864 series) with CEX‑Bus

- S800 I/O modules and termination units (e.g., TU8xx series)

- ModuleBus extension elements (e.g., TB820/TB820V2) where longer distances or fiber links are required

- CEX‑Bus interlink cable and DIN‑rail mounting accessories appropriate for your cabinet

Reviews

There are no reviews yet.