Description

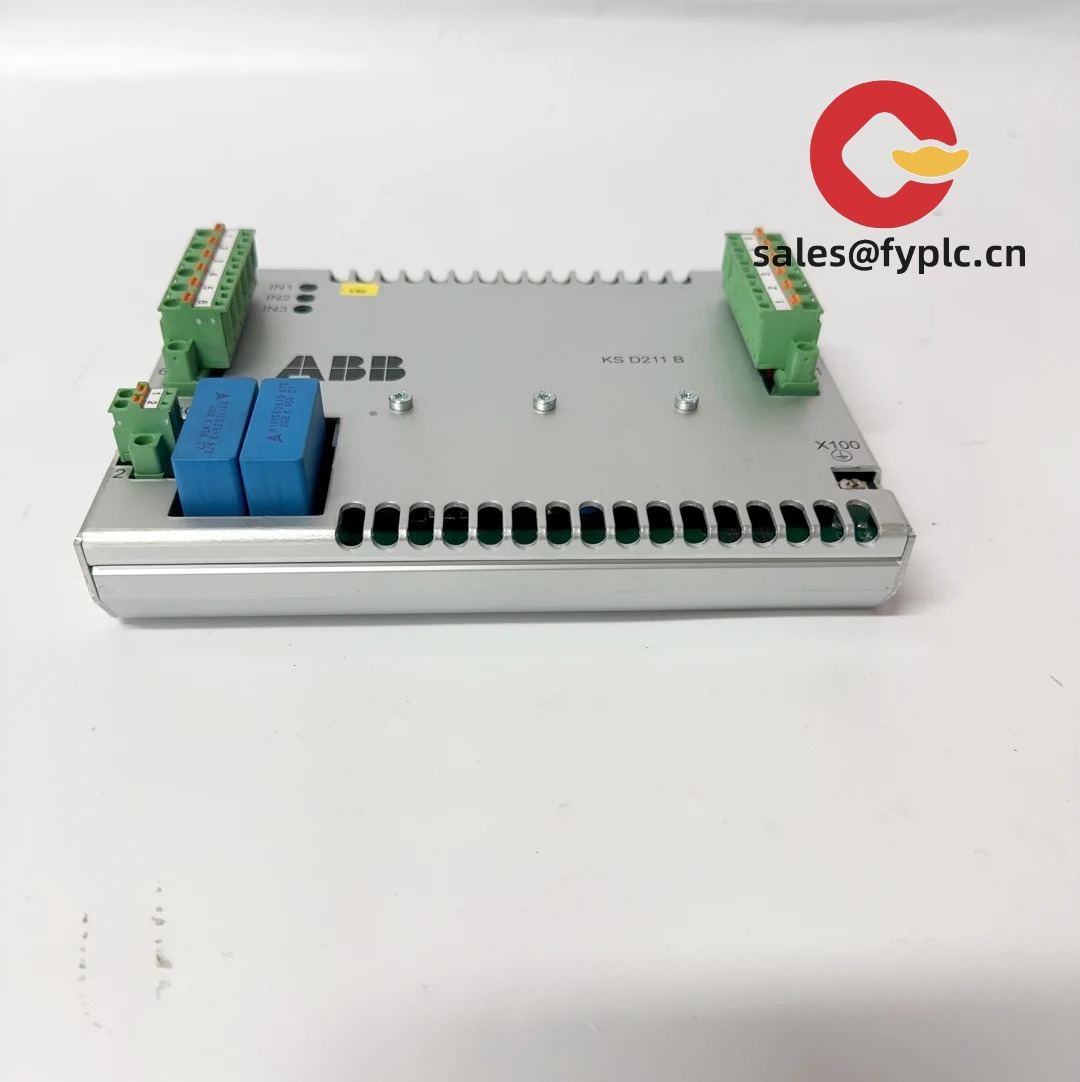

ABB KSD211B (3BHE022455R1101) – Control/Interface Board for ABB Drive and Process Systems

The ABB KSD211B, order code 3BHE022455R1101, is a board-level module used as a control/interface element inside ABB drive and process control cabinets. From my experience, it typically serves as a signal conditioning and I/O interface between the host controller and field wiring, helping stabilize analog/digital signals and ensuring reliable feedback to the drive or excitation system. You might notice that it’s designed as a plug-in spare for installed bases where uptime matters and drop-in replacement keeps maintenance windows short.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week when in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment for delivery

- Express options: FedEx, UPS, DHL

Key Features

- Board-level spare for ABB systems – Intended for in-cabinet use as part of ABB drive/control assemblies; minimizes retrofit complexity.

- Stable signal conditioning – Handles mixed analog/digital signals for clean, low‑noise feedback into the host controller, which in many cases improves closed-loop stability.

- Backplane-powered – Typically receives regulated power from the host backplane; no separate PSU wiring, which simplifies replacement.

- Form-fit serviceability – Screw-secured, plug-in design; swap and re-seat without reworking the cabinet layout.

- Installed base continuity – A practical choice to keep legacy ABB lines running without requalification of the whole drive or panel.

Technical Specifications

| Brand / Model | ABB KSD211B (Order code: 3BHE022455R1101) |

| HS Code | 853890 (Parts suitable for use with switchgear/control panels) |

| Power Requirements | Supplied via host backplane; typically low‑voltage DC from the main controller (no separate field PSU) |

| Operating Temperature | 0 to +55 °C (typical for in‑cabinet ABB control boards) |

| Dimensions & Weight | Board-level module; compact footprint, typically < 0.5 kg (varies by revision) |

| Signal Input/Output Types | Mixed analog/digital signal conditioning via backplane and terminal headers (as defined by the host system) |

| Communication Interfaces | Proprietary backplane bus connection; service access through the host controller/tools |

| Installation Method | Internal cabinet mounting; plug-in/screw-secured replacement within ABB drive/control frames |

Application Fields

The KSD211B is typically applied in ABB drive and process control environments where reliable board-level I/O and signal processing are needed. Common scenarios include:

- Industrial drives in metals, paper, mining, and marine segments, where stable feedback and interlocking signals are essential.

- Plant cabinets handling analog transducers (speed, current, temperature) and digital permissives for motor control.

- Service replacements in legacy ABB cabinets to restore full performance without redesigning wiring or logic.

Advantages & Value

- Reliability – Sourced to match ABB system requirements; helps maintain uptime in critical lines.

- Compatibility – Fits into existing ABB frames with minimal adjustments; in many cases no changes to field wiring.

- Cost Control – Board‑level swap avoids full drive replacement; typically short maintenance windows.

- Technical Support – Guidance on identification, test procedures, and safe handling steps before re-energizing.

One thing I appreciate is how straightforward the swap can be—an electrician told us last month, “It slotted in, we restored parameters from the host, and production was back in under an hour.” That seems to be the norm when the cabinet is in good shape and the backplane is clean.

Installation & Maintenance

- Cabinet environment – Install in a clean, dry, ventilated control cabinet. Maintain ambient within 0–55 °C and avoid condensation.

- Handling – Use ESD protection; avoid touching components and connector pins. De‑energize and lock out before removal.

- Mounting – Align with the backplane connector, seat evenly, and secure with the designated screws/standoffs. Do not force connectors.

- Wiring – Reconnect terminal headers per the cabinet drawings. Verify shield terminations and grounding to reduce noise.

- Checks before power-up – Inspect for bent pins, debris, or loose hardware. Confirm parameter/firmware alignment via the host controller.

- Routine care – Periodic cabinet cleaning, verify cooling airflow, and schedule functional checks. Firmware/parameters are managed at the host level; back up prior to any service.

Quality & Certifications

- CE conformity when integrated in ABB systems

- RoHS compliant hardware

- Manufactured under ISO 9001 quality management

- UL/CSA recognition typically applies at the system/cabinet level

If you’re replacing a previous revision, share the full code from the board label and the host controller type. We can typically verify fit and advise on any parameter alignment needed before you schedule the outage.

Reviews

There are no reviews yet.